Upgrading engine components like turbochargers and fuel injection systems can significantly enhance a vehicle's performance and value, but these parts are expensive. Budget-conscious owners have options: aftermarket parts offer comparable performance at lower costs, while focusing on simpler upgrades like air intake systems and exhausts reduces expenses without sacrificing power. Regular maintenance, such as injector cleaning and filter replacements, prevents costly repairs and extends the vehicle's lifespan, ultimately saving money.

In today’s automotive landscape, replacing high-performance engine components can be as expensive as purchasing a new car. This article delves into the top 3 most expensive engine parts to replace and why they carry such a hefty price tag. We’ll explore these components’ critical roles in your vehicle’s performance and efficiency. Additionally, we provide budget-friendly alternatives and tips for owners looking to save on maintenance costs without compromising power.

- Top 3 Expensive Engine Components to Replace

- Why These Parts Carry a High Cost

- Alternatives and Tips for Budget-Conscious Owners

Top 3 Expensive Engine Components to Replace

When it comes to engine components, some replacements carry a hefty price tag due to their advanced technology, specialized materials, and precision engineering. Among the most expensive are the top three: turbochargers, high-performance pistons, and custom fuel injection systems.

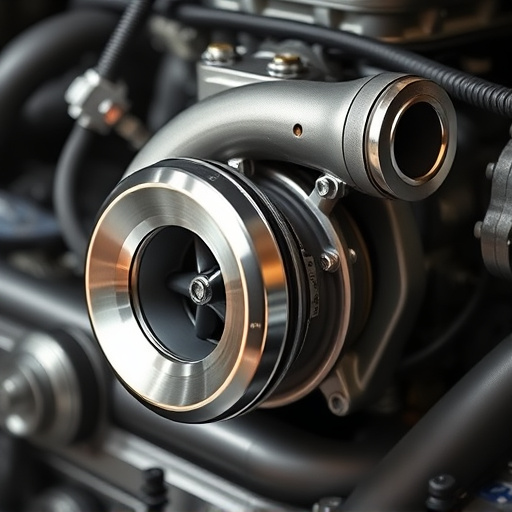

Turbochargers, known for boosting engine power and efficiency, often cost thousands of dollars, with prices varying based on their size, complexity, and manufacturer. High-performance pistons, designed to withstand extreme pressures and temperatures, are another significant expense, especially when crafted from exotic materials like titanium or forged steel. Lastly, custom fuel injection systems, tailored to optimize a vehicle’s performance and fuel efficiency, can run into the thousands, with costs influenced by factors such as precision engineering, advanced materials, and the system’s capabilities, including its ability to handle high-octane fuels and precise metering. These engine components are key areas where investment can significantly impact a vehicle’s performance and value.

Why These Parts Carry a High Cost

The cost of engine components is directly tied to their complexity, precision engineering, and critical role in vehicle performance. High-end parts, like advanced turbos or custom camshafts, are often crafted with meticulous attention to detail, employing cutting-edge materials and manufacturing techniques to enhance power outputs and efficiency. This specialized production process drives up costs significantly.

Furthermore, the reputation and brand associated with these components play a role in their pricing. Premium engine parts manufacturers invest heavily in research and development to stay at the forefront of technology. They ensure their products deliver superior performance, reliability, and longevity, which are all factors that justify the higher price points when compared to more conventional or generic engine components. Additionally, specialized services like custom tuning and fitting, often offered with high-end parts, further add to their overall cost.

Alternatives and Tips for Budget-Conscious Owners

For budget-conscious car owners looking to replace expensive engine components, there are several alternatives and tips to consider. One cost-effective solution is to explore aftermarket parts, which offer similar performance at a fraction of the price. Aftermarket manufacturers often replicate original equipment manufacturer (OEM) designs, ensuring compatibility without compromising quality.

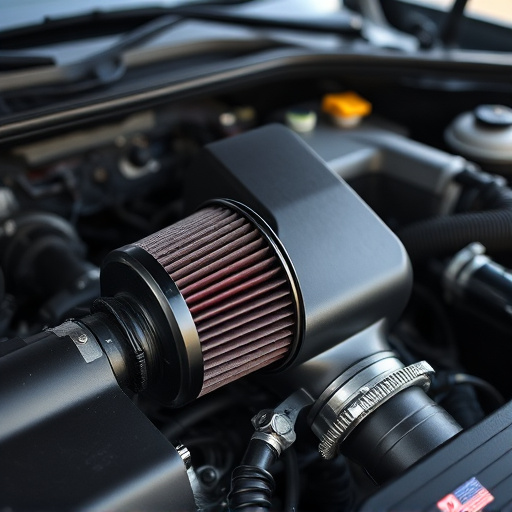

Additionally, focusing on less intricate or high-performance engine components like air intake systems and cat back exhausts can significantly reduce costs. Upgrading these parts doesn’t necessarily affect engine power, but it can improve efficiency. Regular maintenance, such as cleaning fuel injectors and replacing air filters, is another tip to keep costs down. By adhering to a service schedule, owners can prevent major repairs and prolong the life of their vehicles, ultimately saving money in the long run.

When considering the cost of replacing engine components, it’s essential to understand that certain parts are more intricate and specialized, driving up their prices. The top 3 most expensive engine components to replace reflect this – from turbochargers to crankshafts. However, for budget-conscious car owners, there are alternatives and tips available, such as opting for reconditioned or remanufactured parts, which can significantly reduce costs without compromising quality. By staying informed about these options, you can navigate the market for engine components more effectively.