Gas and diesel engines differ in fuel systems, ignition processes, and resulting emission control needs, which impact engine component design. Gas engines have simpler gas fuel systems with spark plugs, offering better fuel economy and requiring specialized brake pads for combustion by-products. Diesel engines use compression-ignition, demanding tougher piston rings due to higher compression ratios and denser fuel. Exhaust systems vary, with gas engines focusing on noise reduction and diesel engines employing SCR, DPF, EGR for NOx and particulate matter control to meet environmental standards.

Explore the intricate differences between gas and diesel engine components in this comprehensive guide. From contrasting fuel systems that power these engines to their unique compression and ignition mechanisms, we delve into what sets these powerplants apart. Furthermore, discover how exhaust systems and emissions control technologies differ, contributing to environmental considerations. Understanding these variations is key for mechanics, enthusiasts, and anyone interested in the intricacies of modern engine components.

- Fuel Systems: Gas vs Diesel Operation

- Compression and Ignition Mechanisms

- Exhaust Systems and Emissions Control

Fuel Systems: Gas vs Diesel Operation

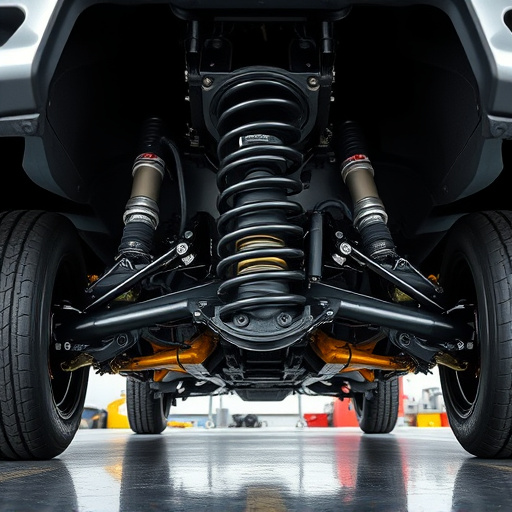

In the realm of engine components, the fuel system plays a pivotal role in the operation of both gas and diesel engines, but with distinct mechanisms. Gas engines rely on a gas fuel system that involves the injection of gasoline into the cylinder, where it is compressed and ignited by a spark plug. This process is relatively simpler and requires a series of fuel injectors precisely timed to deliver the right amount of fuel for efficient combustion. In contrast, diesel engines operate with a diesel fuel system, which compresses air in the cylinder to create heat, and then injects diesel fuel into the hot air mix. This compression-ignition process allows for higher efficiency and power output.

Understanding these fundamental differences is crucial when considering the overall engine design and compatibility of suspension components and brake components. Diesel engines, due to their higher compression ratios and denser fuel, often demand tougher engineering in parts like piston rings and cylinder linings to withstand higher pressures. On the other hand, gas engines may require specialized brake pads that can handle the specific combustion by-products of gasoline without premature wear or degradation in performance.

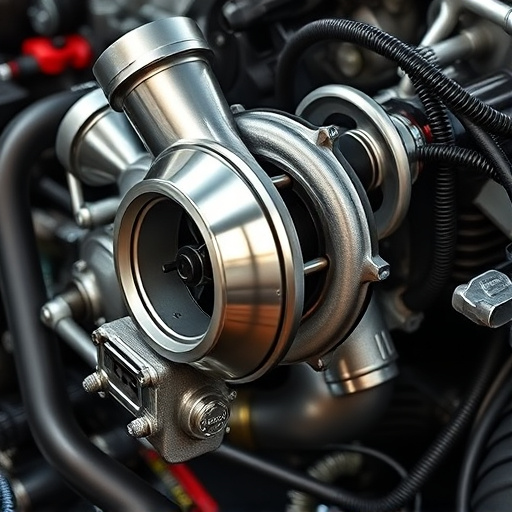

Compression and Ignition Mechanisms

Gas and diesel engines differ primarily in their compression and ignition mechanisms, which significantly impact overall engine performance. In a gas engine, the combustion process begins with the intake of a fuel-air mixture, followed by compression within the cylinder. The compressed mixture is then ignited by a spark plug, leading to rapid expansion that drives the crankshaft. This design relies on a higher compression ratio and results in efficient burning of gasoline, often associated with better fuel economy and lower emissions.

In contrast, diesel engines compress only air, creating high pressure and temperature within the cylinder. The compressed air acts as a kind of ‘spark’ to ignite the injected diesel fuel, leading to a powerful combustion event. This process allows for higher torque output at lower RPMs, making diesel engines popular choices for heavy-duty applications like trucks and construction equipment. Unlike spark plugs in gas engines, performance brakes like durable brake pads, and even high-flow performance air filters aren’t typically tailored to optimize efficiency in diesel engines due to their distinct ignition mechanisms.

Exhaust Systems and Emissions Control

Gas and diesel engines differ significantly in their exhaust systems and emissions control mechanisms, reflecting the inherent combustion processes of each type. In gas engines, where a mixture of air and fuel is ignited within the cylinder, the resulting exhaust gases are generally less toxic compared to their diesel counterparts. This is largely due to the higher combustion temperatures achieved in gas engines, which effectively break down pollutants into less harmful byproducts. As a result, gas engine exhaust systems often rely on simpler designs, focusing primarily on noise reduction through mufflers and resonators, with lesser emphasis on particulate matter filtration.

In contrast, diesel engines use compressed air to ignite a highly concentrated fuel mist, leading to higher levels of nitrogen oxides (NOx) and particulate matter emissions. To mitigate these pollutants, diesel exhaust systems incorporate advanced emission control technologies such as selective catalytic reduction (SCR), diesel particulate filters (DPF), and exhaust gas recirculation (EGR). These components work in tandem to lower NOx and particulate matter levels, ensuring compliance with strict environmental standards. Unlike brake components or suspension components, which are more pertinent to vehicle dynamics, these exhaust systems and emissions control measures are crucial differentiators between gas and diesel engine components.

Understanding the differences between gas and diesel engine components is crucial for both mechanics and car enthusiasts. This article has explored key distinctions in fuel systems, compression and ignition mechanisms, and exhaust systems/emissions control, highlighting how these factors influence performance, efficiency, and environmental impact. By delving into these topics, we’ve provided valuable insights for navigating the world of engine components, empowering readers to make informed decisions regarding their vehicle choices and maintenance.