Fuel delivery systems differentiate gas (electronic injection, spark plugs) and diesel (high-pressure injection, compression ignition) engines. Combustion chambers vary significantly: gas engines use spark plugs for controlled explosions, while diesel engines rely on air compression to autoignite fuel. Exhaust systems manage gases, with gas engines focusing on flow and conversion via catalytic converters, and diesel engines employing robust structures, particulate filters, SCR systems for higher pressure/temperature control. Engine components like headers, pipes, mufflers, and advanced filtration are vital for both types.

Exploring the intricacies of gas and diesel engines reveals a fascinating contrast in their inner workings. This article delves into the fundamental differences between these powerplants, focusing on three key areas: fuel delivery systems, combustion chambers, and exhaust systems with emission controls. By understanding these variations, automotive enthusiasts and mechanics alike can grasp the unique challenges and advantages each engine type presents, ultimately enhancing their knowledge of engine components.

- Fuel Delivery Systems: Gas vs Diesel

- Combustion Chambers: Key Differences

- Exhaust Systems and Emission Controls

Fuel Delivery Systems: Gas vs Diesel

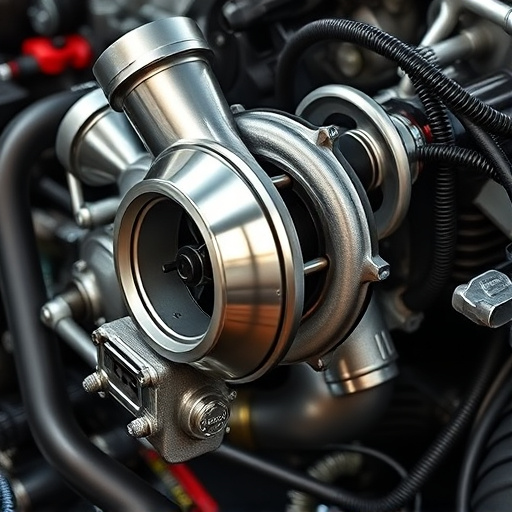

In the realm of engine components, fuel delivery systems play a pivotal role in defining the performance and efficiency of both gas and diesel engines. One of the most significant distinctions between these two types of engines lies in their respective fuel delivery mechanisms. Gas engines rely on a gasolines-based fuel system that typically employs cold air intakes to draw in atmospheric air, which is then mixed with gasoline in a precise ratio before being ignited by a spark plug. This process is often enhanced through the use of electronic fuel injection systems, ensuring optimal combustion and power delivery.

Conversely, diesel engines utilize diesel fuel, which is injected directly into the combustion chamber under high pressure. Unlike gas engines, diesels do not depend on a spark to ignite the fuel-air mixture; instead, they rely on compression ignition. This design leads to more efficient fuel burning and generally better fuel economy. Additionally, while both types of engines have exhaust mufflers designed to reduce noise pollution, diesel exhaust systems often incorporate advanced particulate filters and catalytic converters to address unique emissions challenges associated with diesel combustion.

Combustion Chambers: Key Differences

In terms of engine components, the combustion chamber plays a crucial role as the heart of both gas and diesel engines. However, significant differences exist between these two types, particularly in their design and functionality. Gas engines, known for their efficiency and popularity in vehicles like cars and motorcycles, feature combustion chambers that facilitate the rapid combustion of gasoline. This process involves spark plugs igniting fuel-air mixtures, resulting in a powerful yet controlled explosion that drives pistons. In contrast, diesel engines, commonly found in trucks and heavy machinery, have combustion chambers designed for compression ignition. Here, high-pressure air is compressed until it reaches autoignition temperature, causing the diesel fuel to ignite spontaneously.

These fundamental differences impact various engine aspects. For instance, gas engines typically require a complex system of fuel injection and timing to ensure optimal combustion, while diesel engines rely on precise compression ratios. Moreover, the presence of a cat back exhaust system in gas engines is essential for emission control, whereas diesel engines often incorporate advanced suspension components to manage the higher torque output. Lastly, high-performance parts enthusiasts find unique opportunities in modifying these chambers; for example, tuning diesel combustion chambers can enhance power and efficiency, catering to those seeking top-tier engine performance.

Exhaust Systems and Emission Controls

Exhaust systems play a pivotal role in gas and diesel engines, facilitating the removal of combustion gases. While both types of engines share this fundamental requirement, their exhaust setups differ significantly due to varying combustion processes. In gas engines, exhaust systems primarily focus on directing spent gases away from the engine, with components like headers, pipes, and muffler tips ensuring efficient flow and reducing noise levels. On the other hand, diesel engines involve higher pressures and temperatures, necessitating more robust exhaust structures that can withstand these extremes.

Emission controls are another critical aspect where gas and diesel engines diverge. Gas engines rely on catalytic converters to reduce harmful emissions like carbon monoxide and nitrogen oxides. These converters use precious metals to facilitate chemical reactions that transform pollutants into less harmful compounds. Diesel engines, with their compression-ignition technology, employ particulate filters and selective catalytic reduction (SCR) systems. Particulate filters trap and burn off soot particles, while SCR systems inject urea to convert nitrogen oxides into harmless nitrogen and water. These emission control strategies reflect the distinct combustion characteristics of gas and diesel engine components.

Understanding the distinctions between gas and diesel engine components is key for both vehicle owners and mechanics. Each system has unique characteristics, from fuel delivery methods to combustion processes and exhaust management. By grasping these differences, users can make informed decisions regarding maintenance, repairs, and even preferences when choosing a vehicle. These insights are essential in today’s market, where both types of engines offer distinct advantages, contributing to the diverse landscape of automotive technology.