Engine performance and efficiency hinge on a complex interplay of numerous components, including cylinder heads, pistons, valves, crankshafts, intake systems, and exhaust systems. Each architecture, from inline to rotary, offers unique advantages and challenges in weight distribution, power delivery, and cooling. Understanding these relationships is vital for maximizing vehicle functionality, ensuring smooth operation, and promoting engine longevity.

Unravel the intricate relationship between engine components and discover how each element plays a pivotal role in an automobile’s performance. This article provides a comprehensive guide, starting with an overview of engine architecture, followed by an exploration of interconnected parts and their symbiotic collaboration. We delve into optimizing performance through key component relationships, offering insights that every automotive enthusiast and mechanic should find enlightening.

- Engine Architecture: The Big Picture Overview

- Interconnected Parts: How They Collaborate

- Optimizing Performance: Key Component Relationships

Engine Architecture: The Big Picture Overview

The heart of any vehicle lies in its engine, a complex system where numerous components work in harmony to convert fuel into power. Understanding the relationship between these engine components is key to unlocking optimal performance and efficiency. At its core, an engine’s architecture defines how these parts interact, influencing everything from fuel combustion to force transmission.

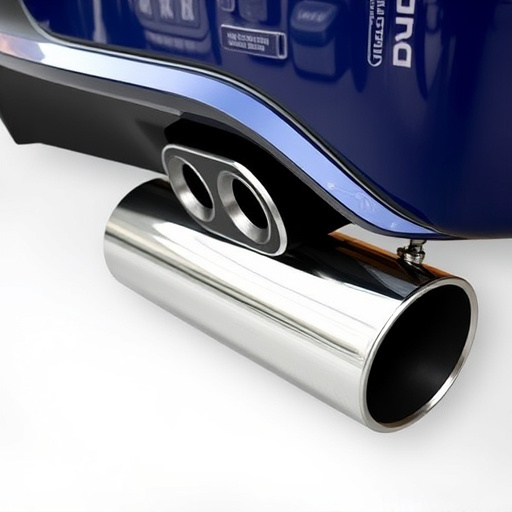

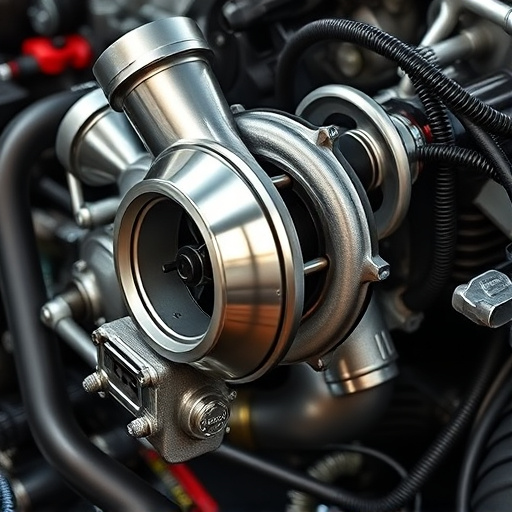

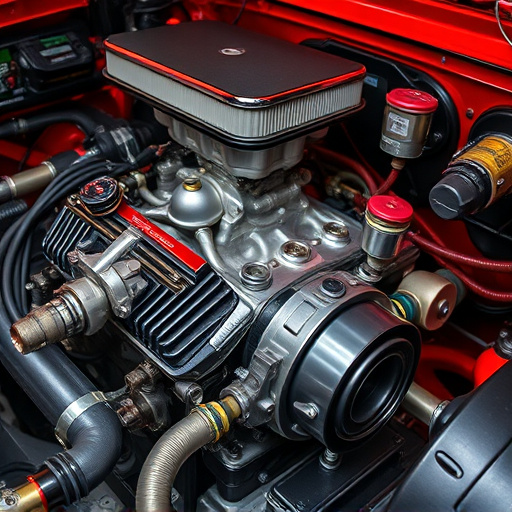

Engine architectures vary, but common designs include inline, V-type (V6, V8), flat (boxer), and rotary configurations. Each layout has unique advantages and disadvantages, impacting factors like weight distribution, power delivery, and cooling efficiency. For instance, a V-type engine’s compact design and balanced power output make it popular for many modern vehicles. Conversely, a boxer engine’s flat layout can enhance balance but may require more space. Intake components and exhaust systems, playing vital roles in airflow management, are also influenced by architecture choices. A well-designed exhaust system, for example, can enhance performance exhaust, while carefully engineered intake components ensure efficient air intake, both contributing to overall engine performance.

Interconnected Parts: How They Collaborate

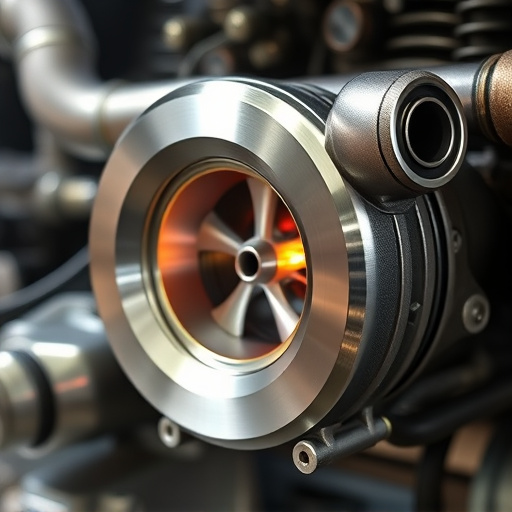

In the intricate world of automotive engineering, understanding the relationship between engine components is akin to solving a complex puzzle. Each component plays a pivotal role in the grand symphony of an engine’s operation. From the moment the ignition switches on, a harmonious dance commences. The cylinder head, for instance, acts as the central conductor, orchestrating the precise timing of fuel and air intake through meticulously designed intake components. This strategic collaboration ensures optimal combustion, a key factor in determining overall performance air filters efficiency.

The engine’s heart beats stronger thanks to the interplay between crucial parts like the pistons, connecting rods, and crankshaft. These interconnected elements work in unison to translate the linear motion of pistons into rotational force, driving the vehicle’s wheels via the transmission system. Even seemingly minor components, such as the timing belt or chain, play a vital role in maintaining this synchrony, ensuring the intake and exhaust valves open and close at the right moments. This seamless coordination is what keeps the engine purring smoothly, with performance exhaust gases efficiently expelled to enhance power and efficiency.

Optimizing Performance: Key Component Relationships

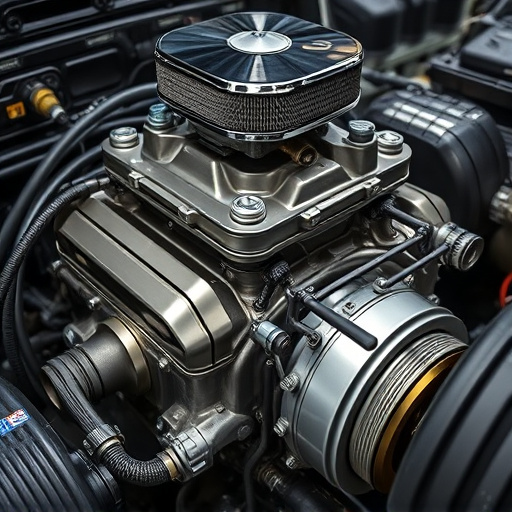

In the intricate world of engines, understanding the relationship between various components is akin to solving a complex puzzle. Each piece plays a unique role in ensuring optimal performance and efficiency. The interplay between engine components, such as the cylinder head, pistons, valves, and crankshaft, is a delicate balance that can significantly impact overall functionality. By examining these interactions, mechanics and enthusiasts alike can unlock ways to enhance power output while promoting longevity.

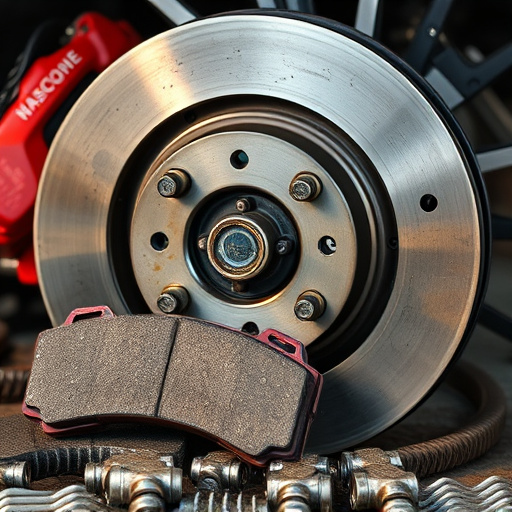

Optimizing performance extends beyond mere engine speed; it involves streamlining airflow with carefully designed intake components, ensuring clean fuel combustion. Even seemingly unrelated parts like the air filter kits contribute to this process by filtering out contaminants, allowing for smoother airflow. Moreover, considering the synergy between the brakes and other mechanical elements is vital for maintaining control and stability, especially during high-performance scenarios. Effective synchronization of these components ultimately leads to a seamless driving experience, proving that every part within an engine has its place in creating a harmonious functional unit.

Understanding the intricate relationship between engine components is key to unlocking optimal performance and efficiency. By grasping how each part collaborates within the bigger picture of engine architecture, enthusiasts and mechanics alike can make informed decisions to enhance power, improve fuel economy, and ensure longevity. This knowledge empowers individuals to navigate the complex world of engine components, fostering a deeper appreciation for the symphony of motion that powers our vehicles.