The internal combustion engine's core structure includes cylinders, pistons, and blocks, vital for transforming fuel into mechanical energy. Cylinders house pistons that compress and ignite fuel to generate power activating the crankshaft, propelling vehicle wheels. Engine block provides structural support and houses cooling & oil systems. Modifying engine components like coilover kits or upgrading brake rotors can enhance efficiency. Combustion, valve control, spark plugs, and strategic placement of parts influence performance. Cooling and lubrication systems are crucial for maintaining component health and longevity.

Unravel the intricate dance of engine components and discover how each element contributes to seamless power generation. From the foundational blocks and cylinders to the delicate interplay of valves and spark plugs, every part plays a pivotal role. This article delves into the core aspects, exploring the basic engine layout, power generation mechanisms, and essential cooling & lubrication systems. By understanding these key components, you gain insights into the intricate symphony that keeps engines running smoothly.

- The Basic Engine Layout: Cylinders, Pistons, and Blocks

- Power Generation: Combustion, Valves, and Spark Plugs

- Cooling and Lubrication: Keeping the Engine Running Smoothly

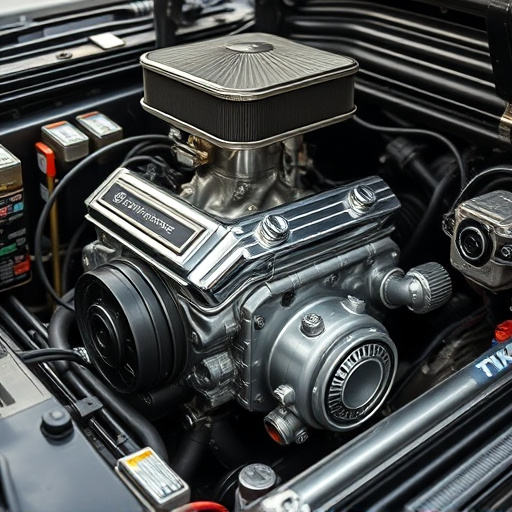

The Basic Engine Layout: Cylinders, Pistons, and Blocks

The heart of any internal combustion engine lies in its basic layout—a combination of cylinders, pistons, and blocks that work together to convert fuel into mechanical energy. Cylinders, typically arranged in rows or V-configurations, are the chambers where the magic happens. Inside each cylinder, a piston moves up and down, compressing the fuel mixture and igniting it through a spark plug, thereby generating power. This powerful movement is what drives the engine’s crankshaft, which in turn powers the vehicle’s wheels.

The block, or engine case, houses and supports all these components, providing them with the structural integrity they need to operate at high pressures and temperatures. The block also contains vital cooling systems and oil passages that ensure the engine stays cool and lubricated during operation. For those looking to enhance their vehicle’s performance, modifying these core engine components—using high-performance parts like coilover kits or upgrading brake rotors for better stopping power—can significantly impact overall engine performance.

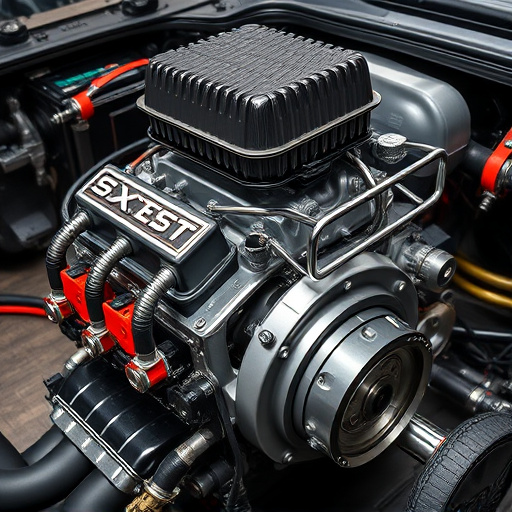

Power Generation: Combustion, Valves, and Spark Plugs

Power generation in an engine is a complex interplay between various components that work in harmony to convert fuel into motion. At the heart of this process lies combustion, where the ignition of fuel and air creates a powerful force. This force is then channeled through valves, acting as gateways, opening and closing at precise intervals to regulate the flow of gases entering and exiting the engine cylinders.

The timing and synchronization of these valves are critical for optimal vehicle performance. Spark plugs play a pivotal role in this mechanism by igniting the combustible mixture inside the cylinders, ensuring efficient combustion. The strategic placement and timing of spark plugs directly impact engine power, torque, and overall vehicle exhaust performance, often visible through sleek exhaust tips that enhance not just aesthetics but also signal the engine’s capabilities.

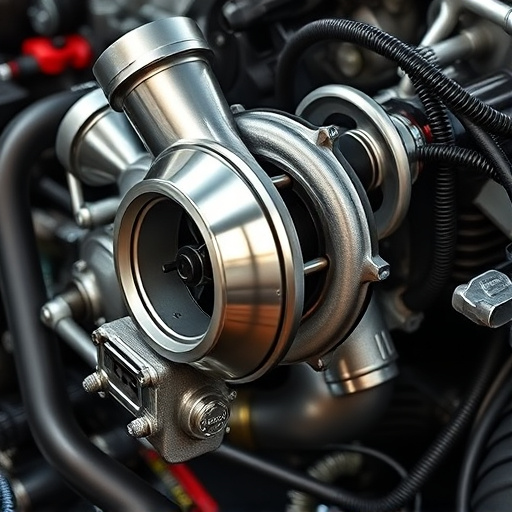

Cooling and Lubrication: Keeping the Engine Running Smoothly

Cooling and Lubrication play a pivotal role in ensuring the optimal performance and longevity of engine components. These systems work hand-in-hand to maintain the engine’s operating temperature within safe limits, preventing overheating that could lead to serious damage. Efficient cooling involves the use of coolants that circulate through the engine, absorbing heat and dissipating it via radiators or other cooling mechanisms. This process not only keeps the engine from shutting down due to excessive heat but also supports the overall thermal stability required for seamless operation.

Lubrication, on the other hand, reduces friction between moving parts of the engine, such as pistons, valves, and bearings. High-quality engine oil, when properly circulated, creates a thin film that separates these components, minimizing wear and tear. Regularly changing engine oil and using high-performance air filters to keep intake components clean are crucial practices for maintaining optimal lubrication. These measures ensure not just the smooth operation of individual parts but also contribute significantly to the overall performance and reliability of the entire engine.

Understanding the intricate relationship between engine components is key to optimizing performance and efficiency. By grasping the basic layout, power generation processes, and critical systems like cooling and lubrication, you gain valuable insights into how these parts work together seamlessly. This knowledge empowers you to make informed decisions when maintaining or upgrading your engine, ensuring its longevity and peak functionality. Each component plays a vital role, from cylinders and pistons driving the combustion process to spark plugs igniting the fuel mix, all contributing to the harmonious symphony of a well-oiled machine.