Performance exhaust systems require materials resistant to heat, pressure, and corrosion, optimizing gas flow for better engine performance. Stainless steel, aluminum, and titanium are top choices catering to diverse automotive needs. Advanced materials like high-strength steels, composites, and ceramics enhance efficiency, durability, and fuel economy. Future trends include carbon fiber and high-performance polymers offering lighter weight, enhanced durability, and superior thermal management for optimal system performance in high-octane vehicles.

Performance exhaust systems are a crucial upgrade for automotive enthusiasts seeking enhanced power and sound. Manufacturing these systems requires a blend of traditional materials and cutting-edge composites. From durable metals like stainless steel to advanced alloys, each component contributes to improved efficiency and longevity. This article explores the key materials revolutionizing performance exhaust system design, highlighting common metals, advanced innovations, and futuristic composites that push the boundaries of automotive technology.

- Common Metals and Alloys for Performance Exhaust Systems

- Advanced Materials Enhancing Efficiency and Durability

- Innovative Composites Shaping Future Exhaust Technology

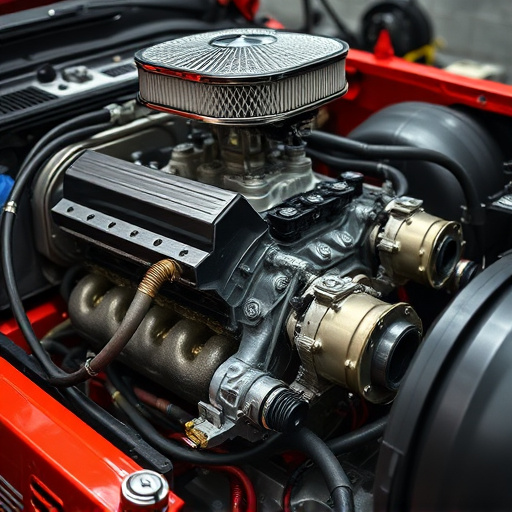

Common Metals and Alloys for Performance Exhaust Systems

Performance exhaust systems require materials that can withstand extreme heat, pressure, and corrosive gases while ensuring optimal gas flow for enhanced engine performance. Common metals and alloys used in their manufacturing include stainless steel, aluminum, and titanium. Stainless steel is highly resistant to corrosion and offers excellent durability, making it a top choice for many high-performance exhaust systems. This metal’s non-reactive properties prevent it from being affected by the hot gases and chemicals present in engine exhaust.

Aluminum, another prevalent material, is lighter than stainless steel, which makes it ideal for race cars and vehicles equipped with suspension kits or coilover kits. Its excellent heat conductivity ensures efficient temperature management within the exhaust system. Titanium, known for its exceptional strength-to-weight ratio, is used in premium performance exhaust systems due to its ability to handle extreme conditions while keeping weight to a minimum. This material’s resistance to corrosion and oxidation further enhances its appeal in demanding automotive applications.

Advanced Materials Enhancing Efficiency and Durability

In the realm of manufacturing performance exhaust systems, advanced materials play a pivotal role in enhancing both efficiency and durability. These cutting-edge substances are meticulously chosen to withstand the extreme conditions encountered during vehicle operation, ensuring optimal performance over an extended period. For instance, high-strength steels and specialized alloys are increasingly utilized for exhaust pipes, muffler tips, and other critical components, providing superior resistance to corrosion and heat stress while allowing for more lightweight designs—a key factor in improving vehicle fuel efficiency.

Beyond traditional materials, innovative composites and advanced ceramic technologies are also finding their place in performance exhaust systems. These materials offer unparalleled thermal stability, reducing heat transfer and minimizing expansion issues. Moreover, they contribute to improved sound deadening properties, enhancing the overall silencing effectiveness without compromising airflow. By integrating these advanced materials, manufacturers can deliver top-tier vehicle performance, ensuring that every drive is both powerful and efficient.

Innovative Composites Shaping Future Exhaust Technology

The future of performance exhaust systems is being reshaped by innovative composites, pushing the boundaries of what’s possible in automotive engineering. Traditional metal components are being replaced or augmented with advanced materials like carbon fiber and high-performance polymers. These composites offer significant advantages, such as reduced weight, increased durability, and enhanced thermal management—all crucial factors for optimizing exhaust system performance. By integrating these materials, manufacturers can create lighter, more efficient systems that withstand the extreme conditions of high-performance vehicles.

This shift towards innovative composites also opens up new design possibilities. Exhaust systems are no longer confined by the limitations of metal fabrication. Engineers can now craft intricate geometries and complex shapes, allowing for better airflow and gas flow dynamics. Moreover, these advanced materials often exhibit superior resistance to corrosion and wear, ensuring longer lifespans even under harsh driving conditions. As a result, performance exhaust systems are becoming more efficient, powerful, and reliable, catering to the demands of automotive enthusiasts who seek both speed and style.

In the realm of performance exhaust system manufacturing, a blend of traditional metals and cutting-edge materials defines modern innovation. Common metals like stainless steel remain staples for their durability and corrosion resistance, while advanced alloys offer enhanced thermal conductivity. Moving forward, innovative composites are revolutionizing exhaust technology by providing lightweight solutions that improve fuel efficiency without compromising strength. As the industry continues to evolve, these key materials drive performance exhaust systems toward greater efficiency, longer lifespans, and reduced environmental impact.