Engine components like pistons, valves, and blocks are crucial for vehicle power. Regular maintenance prevents failures of air filters, brake rotors, thermostats, etc., enhancing reliability and safety. Timely replacement of worn parts and adherence to service intervals ensure optimal performance, especially in high-performance vehicles. Proactive checks on all engine components mitigate risks of breakdowns and improve driver confidence.

Engine components are the backbone of any vehicle’s performance, ensuring smooth and efficient operation. However, failure in these critical parts can lead to severe consequences. This article delves into the intricate world of engine components, exploring their vital roles and the widespread impact of failures. We uncover common issues, from cylinder heads to piston rings, and present effective strategies to prevent and manage their effects, ultimately guiding vehicle owners towards optimal performance and safety.

- Understanding Engine Components: Their Role and Significance

- Common Engine Component Failures and Their Impact

- Strategies for Preventing and Mitigating Failure Effects

Understanding Engine Components: Their Role and Significance

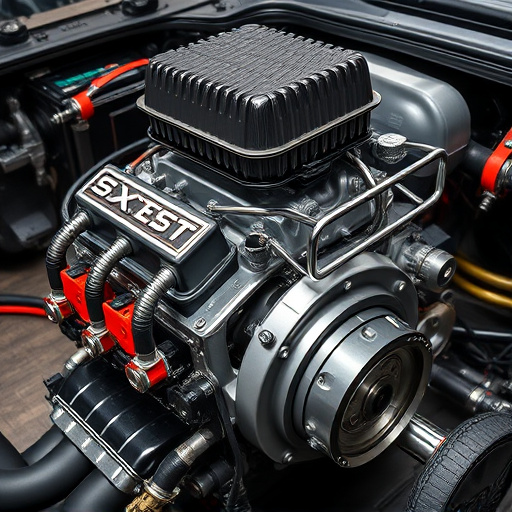

Engine components are the backbone of any vehicle’s operation, responsible for converting fuel into power. These critical elements include various parts such as pistons, valves, cams, and the all-important engine block. Each component plays a specific role in ensuring smooth and efficient operation. For instance, air intake systems deliver the right amount of air to mix with fuel for optimal combustion, while performance exhaust systems facilitate the efficient expulsion of spent gases, enhancing overall vehicle performance.

When these engine components fail, it can have significant impacts on vehicle performance. A malfunctioning piston, for example, can lead to reduced engine compression and power output. Faulty valves may cause poor fuel efficiency or even prevent the engine from starting. High-performance parts are designed to enhance engine capacity and speed, but they also require meticulous care and regular maintenance to avoid premature failure. Regular checks on these components, especially in high-performance vehicles or those with modified engines, can help prevent unexpected breakdowns and ensure a seamless driving experience.

Common Engine Component Failures and Their Impact

Common Engine Component Failures and Their Impact

Some of the most prevalent engine component failures include issues with the air intake systems, which can lead to decreased performance and efficiency. A clogged or faulty air filter, for instance, restricts airflow, causing the engine to work harder and potentially leading to overheating. Another critical area is the brake rotors; their wear and tear can result in reduced braking power, increasing stopping distances and compromising safety.

Additionally, intake components such as the thermostat or sensor malfunctions can disrupt the engine’s cooling system, leading to overheating during operation. These failures not only impact vehicle performance but also pose significant safety risks. Regular maintenance and timely replacements of these essential engine components are crucial to ensure optimal vehicle operation and driver safety on the road.

Strategies for Preventing and Mitigating Failure Effects

Preventing and mitigating the effects of engine component failure is paramount for maintaining optimal vehicle performance and safety. Regular maintenance plays a crucial role in forestalling catastrophic breakdowns. Routine checks, such as inspecting and replacing worn-out parts like spark plugs, oil filters, and belts, can significantly reduce the risk of sudden failures. Additionally, adhering to recommended service intervals ensures that essential components, including the catalytic converter (cat back exhaust) and intake components, remain in top condition.

Beyond maintenance, prioritizing safety and performance involves scrutinizing less obvious but critical elements like suspension components. Well-maintained suspension parts contribute to better control and handling, thereby enhancing driver confidence and reducing the likelihood of accidents. By integrating proactive measures into vehicle care routines, drivers can effectively mitigate the adverse effects of engine component failures, ensuring a smoother, safer driving experience.

Engine components are the backbone of any vehicle’s performance, and their failure can lead to significant operational issues. By understanding the critical role these parts play, we can implement effective strategies to prevent and mitigate failures. Regular maintenance, prompt replacement of worn-out components, and staying informed about common failure modes are key to ensuring smooth vehicle operation. Keeping an eye on these essential elements can save time, money, and potentially avoid hazardous situations on the road.