Engine components crucial for vehicle performance and efficiency. Common issues include faulty sensors, worn spark plugs, damaged pistons, and camshaft/crankshaft problems, leading to reduced fuel efficiency, power loss, unusual noises, and engine failure. Regular maintenance, monitoring temperatures and oil levels, upgrading exhaust systems or air intakes, and ensuring proper air intake systems are key for optimal engine health. Accurate troubleshooting requires advanced diagnostic tools like OBD-II scanners, pressure gauges, flow meters, and compression testers, enabling technicians to resolve issues effectively, enhancing vehicle efficiency and reliability. Structured problem-solving process begins with visual inspections and basic checks, leading to replacements or complex overhauls based on identified problems. Upgrading to high-performance air filters can enhance engine intake and performance, while intricate components require expert advice due to depth of knowledge needed.

Struggling with a car’s performance? It might be time to troubleshoot those stubborn engine component issues. This guide breaks down common problems affecting your vehicle’s powerplant, from sensor malfunctions to fuel injection woes. Learn to leverage diagnostic tools for accurate assessments and discover effective repair strategies tailored to these specific engine components. Get ready to breathe new life into your car with informed, targeted solutions.

- Identify Common Engine Component Problems

- Diagnostic Tools for Accurate Assessment

- Effective Troubleshooting and Repair Strategies

Identify Common Engine Component Problems

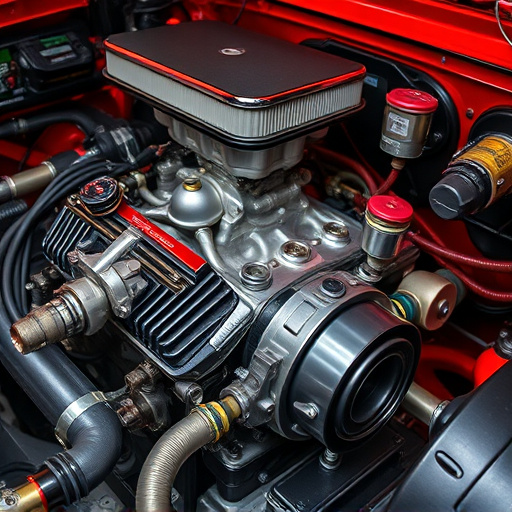

Engine components play a critical role in the overall performance and efficiency of your vehicle. Identifying common issues with these parts is an essential step in troubleshooting and maintaining optimal engine health. Some of the most frequent problems include faulty sensors, clogged or worn-out spark plugs, damaged pistons, and issues with the camshaft or crankshaft. These problems can lead to a range of symptoms, such as reduced fuel efficiency, poor engine power, unusual noises, and even complete engine failure.

Regular maintenance and prompt attention to warning signs are key in mitigating these issues. For instance, monitoring engine temperatures and oil levels can help detect problems with cooling systems or oil leaks. Upgrading components like installing high-performance exhaust systems or cold air intakes can significantly enhance airflow and combustion efficiency, resulting in better overall performance. Furthermore, ensuring the proper functioning of air intake systems is crucial for optimal fuel delivery and power output.

Diagnostic Tools for Accurate Assessment

When troubleshooting common engine component issues, having the right diagnostic tools is paramount for an accurate assessment. Modern vehicles are equipped with advanced onboard diagnostics (OBD) systems that provide valuable data on various engine components. These systems include sensors, actuators, and control modules that work together to monitor and regulate engine performance. Utilizing OBD-II scanners, which can interface with these systems, allows mechanics to access real-time data, identify fault codes, and pinpoint problematic areas within the engine.

In addition to OBD systems, other diagnostic tools such as pressure gauges, flow meters, and compression testers are essential for a comprehensive evaluation. Air filter kits and intake components, like cold air intakes, play significant roles in engine performance. Regularly inspecting and replacing these parts can help maintain optimal airflow, ensuring the engine receives the right mix of air and fuel. By combining these diagnostic tools with thorough inspections, technicians can effectively troubleshoot and resolve issues related to engine components, leading to improved vehicle efficiency and reliability.

Effective Troubleshooting and Repair Strategies

Effective troubleshooting involves a systematic approach to identifying and rectifying issues with engine components. Start by isolating the problem through visual inspection and basic functional checks. Look for signs of damage, leaks, or unusual noises that could point to specific components like spark plugs, fuel injectors, or sensor malfunctions.

Once identified, repair strategies can range from simple replacements (e.g., air filters or oil pans) to more complex tasks like overhauling an engine block or replacing exhaust systems for improved performance exhaust. Upgrading to high-performance air filters can boost engine intake and overall vehicle performance. Remember, proper troubleshooting requires a good understanding of engine mechanics, so consulting service manuals or seeking expert advice is often beneficial, especially when dealing with intricate engine components.

Troubleshooting common engine component issues is a vital skill for any vehicle owner or mechanic. By understanding the various problems that can arise with different engine parts, utilizing diagnostic tools for accurate assessments, and employing effective repair strategies, you can efficiently navigate through these challenges. Regular maintenance and prompt action when issues are identified are key to keeping your engine running smoothly, ensuring optimal performance, and preventing more severe damage to these critical engine components.