Timing belts are essential for synchronizing engine components (crankshaft, camshaft, valves) to ensure optimal fuel injection, valve motion and ignition timing, maximizing power output and energy efficiency. Well-maintained timing belts extend engine lifespan, linked with systems like suspension and high-performance air filters, enhancing vehicle stability and efficiency. Regular care is critical for peak performance, preventing reduced efficiency, increased emissions, handling problems and engine damage. Modern engines use advanced engineering like VVT to achieve precise engine components interaction.

In today’s advanced automotive landscape, precise synchronization of engine components is paramount for optimal performance and efficiency. Timing belts play a crucial role in this intricate dance, coordinating the movements of various parts to ensure seamless operation. This article delves into the fascinating world of timing belts, exploring their fundamental role in engine functionality and how they synchronize engine components with meticulous accuracy. By understanding these mechanisms, we gain insights into the intricate tapestry of modern vehicle engineering, where every component works in harmony for enhanced power and reduced wear.

- Understanding Timing Belts' Role in Engine Functionality

- Components Affected by Precise Synchronization

- The Mechanics Behind Ensuring Timely Component Interaction

Understanding Timing Belts' Role in Engine Functionality

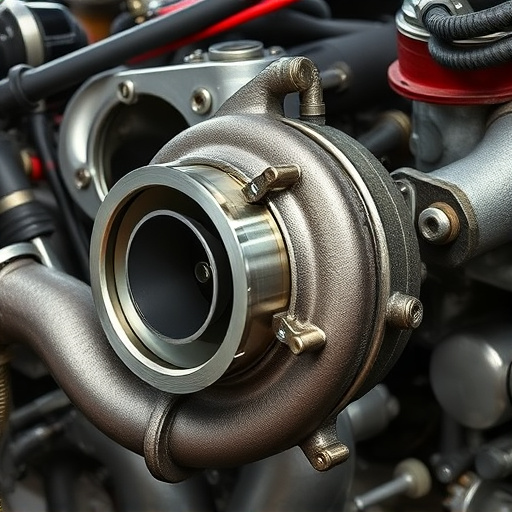

Timing belts play a pivotal role in synchronizing the movements of various engine components, ensuring smooth and efficient operation. They connect and coordinate the crankshaft with the camshaft, allowing them to work in harmony. This coordination is critical for several functions, including fuel injection, valve opening and closing, and compression within the cylinders.

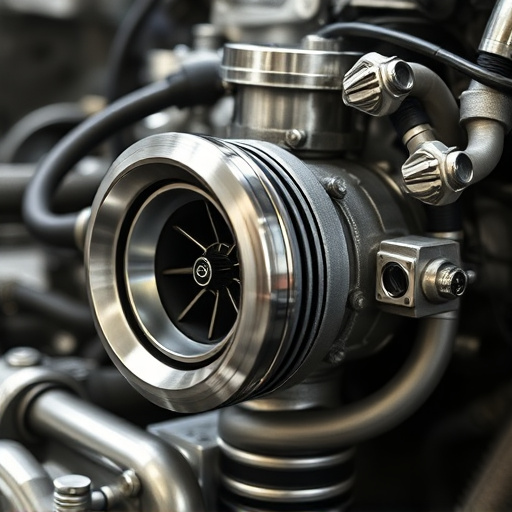

The precise timing facilitated by timing belts is essential for optimal engine performance. It ensures that each cylinder fires at the right moment, maximizing power output while minimizing energy wastage. Furthermore, well-maintained timing belts can contribute to the longevity of not just the engine but also other critical components like suspension parts and high-performance air filters, ultimately enhancing overall vehicle stability and efficiency.

Components Affected by Precise Synchronization

In a vehicle’s engine, precise synchronization among various components is paramount for optimal performance and efficiency. When an engine runs, multiple parts must work in perfect harmony to ensure smooth and seamless operation. Components like the camshaft, crankshaft, and valves are directly affected by the timing belt’s accuracy. These elements govern the intake and exhaust cycles, fuel injection, and ignition timing—any misalignment can lead to reduced vehicle performance air filters efficiency, increased emissions, and even damage to critical engine parts.

Suspending kits and other performance enhancements often highlight the need for precise synchronization. As modifications are made to a vehicle’s suspension or power outputs, maintaining accurate timing becomes even more crucial. An improperly timed engine can cause uneven tire wear, handling issues, and decreased overall vehicle performance. Therefore, ensuring the timing belt is in top condition and properly maintained is essential for both stock and modified vehicles alike, guaranteeing optimal performance and longevity of these critical engine components.

The Mechanics Behind Ensuring Timely Component Interaction

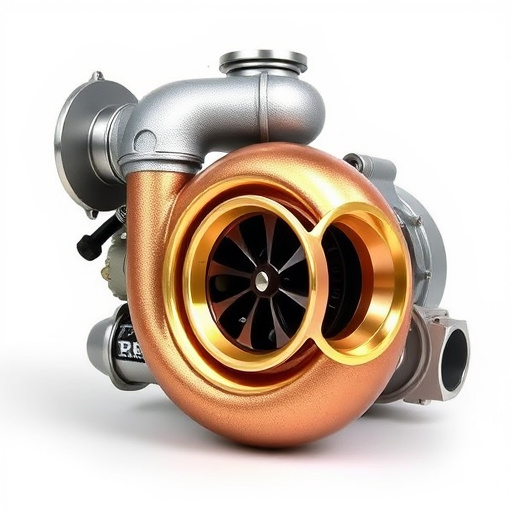

The timing belt, a crucial component in internal combustion engines, serves as the maestro conducting the precise interaction of various engine components. Its mechanics are intricate and vital to the smooth operation of any automotive powerplant. The belt’s primary role is to synchronize the rotation of the crankshaft with that of the camshaft, ensuring valves open and close at precisely the right moments during each cylinder’s intake and exhaust strokes.

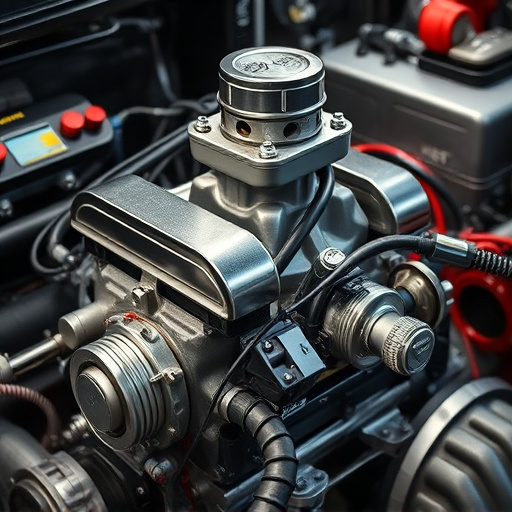

This synchronization is achieved through a carefully engineered system that includes gears, pulleys, and sensors. In modern engines, advanced timing belt designs, coupled with technologies like variable valve timing (VVT), allow for even greater precision. For instance, cold air intakes and exhaust systems with integrated sensors can communicate with the engine control unit to adjust timing belts’ operation, optimizing performance and fuel efficiency. Similarly, the strategic placement of exhaust tips can enhance airflow, further contributing to the timely interaction of engine components.

Timing belts play a pivotal role in synchronizing critical engine components accurately, ensuring smooth and efficient operation. By maintaining precise timing, these belts facilitate seamless interaction among various parts, leading to optimal engine performance. Understanding the mechanics behind this process highlights the importance of regular maintenance and timely replacements for optimal vehicle health and fuel efficiency.