When major engine damage occurs, a thorough assessment identifies affected components including cylinder head, pistons, valves, spark plugs, and timing systems. Disassembly, cleaning, and meticulous reassembly with high-quality parts are crucial for engine rebuilding. Focus on proper alignment and installation of key components like the cylinder head, camshaft, and crankshaft. Upgrades can enhance performance and safety standards through rigorous testing before integration into the vehicle, ensuring optimal functionality of engine components.

After sustaining major damage, rebuilding engine components is a meticulous process that requires careful assessment and skilled execution. This comprehensive guide delves into the intricate steps of repairing engine parts, from identifying affected components to reassembling for optimal performance. By understanding the extent of the damage, disassembling with precision, and replacing essential parts, you can restore functionality and enhance your engine’s longevity. Each section—assessing damage, disassembling, replacing, and reassembling—serves as a crucial step in this transformative journey.

- Assessing Engine Damage: Identifying Components Affected

- Disassembling and Cleaning: Preparing for Reconstruction

- Replacing and Reassembly: Restoring Functionality and Performance

Assessing Engine Damage: Identifying Components Affected

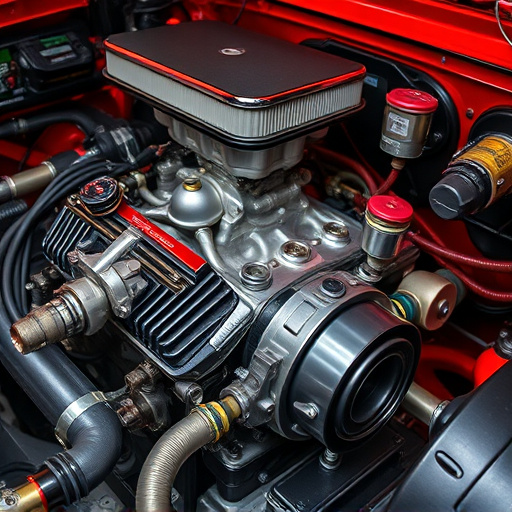

When dealing with major engine damage, the first step is a thorough assessment to identify which components have been affected. This involves carefully examining the engine for any visible signs of wear, corrosion, or damage. Check for leaks in the oil, coolant, and fuel systems, as these can point to specific issues. Remove the engine cover and inspect each component manually and with the aid of diagnostic tools. Pay close attention to the cylinder head, pistons, valves, and spark plugs—critical parts that often require replacement after severe damage.

Additionally, look into the condition of the air intake systems and air filter kits, as dirty or clogged filters can lead to reduced engine performance and even further damage. Performance air filters might be needed for high-performance engines, but standard replacements are sufficient for most cases. Other affected areas could include the timing belt, chain, or gears; these are essential for the engine’s proper functioning and must be replaced if damaged.

Disassembling and Cleaning: Preparing for Reconstruction

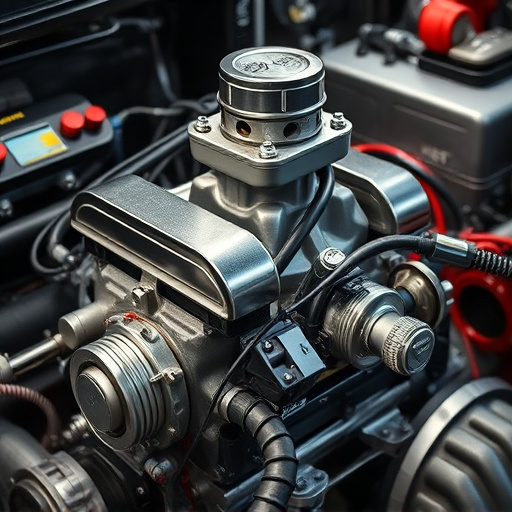

Disassembling and cleaning is a crucial step in the process of rebuilding engine components after major damage. It’s essential to carefully take apart the affected parts, paying close attention to how they were originally assembled. This meticulous approach ensures that every component is properly assessed for damage and that no foreign debris or contaminants remain within the engine’s intricate system.

Proper disassembly involves carefully separating each part, using specialized tools and techniques suitable for the specific engine components. Once separated, a thorough cleaning process begins. High-performance parts, such as performance air filters and air filter kits, often require special care to remove built-up grime and debris. This meticulous cleaning ensures that when reassembled, the engine components function optimally, enhancing overall engine performance.

Replacing and Reassembly: Restoring Functionality and Performance

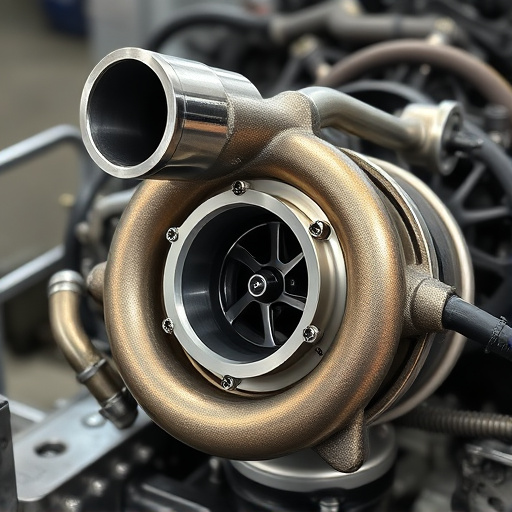

After carefully disassembling the damaged engine components, the next crucial step is their replacement and reassembly. This process involves sourcing high-quality, compatible parts to ensure they fit seamlessly into the existing engine structure. Every part, from pistons and valves to bearings and gaskets, must be in pristine condition or replaced to maintain optimal performance.

Reassembly begins with precise alignment and installation of critical components like the cylinder head, camshaft, and crankshaft. It’s here where attention to detail is paramount; proper torque specifications and clearances must be maintained throughout. Upgrading certain parts, such as installing high-performance brakes or a cat back exhaust system, can further enhance engine functionality and overall vehicle performance. Once reassembled, the engine undergoes rigorous testing to ensure its reliability and adherence to safety standards before being integrated back into the vehicle.

Rebuilding engine components after major damage is a meticulous process that requires careful assessment, disassembly, cleaning, and strategic replacement. By following these steps—from identifying affected parts to reassembly and final performance testing—you can restore your engine to its former glory, ensuring optimal functionality and reliability for years to come. This comprehensive guide empowers you to tackle even the most challenging engine component repairs with confidence.