Assess engine damage by inspecting for visible signs and leaks in key components. Disassemble damaged parts, document connections, clean thoroughly, and prepare for reconstruction. Replace or upgrade worn engine components with high-quality, model-specific parts, ensuring proper installation and sealing. Test for leaks and exhaust system integrity after reinstatement.

“Unforeseen events can cause major damage to engine components, but with the right approach, rebuilding is achievable. This comprehensive guide walks you through the process of assessing, disassembling, and restoring your engine’s critical parts after severe damage. From identifying issues like cracks, corrosion, or worn-out bearings to a detailed step-by-step replacement process, you’ll learn how to expertly reinstall functional engine components. By following these expert tips, you can ensure a reliable and efficient engine rebuild.”

- Assessing Engine Damage: What to Look For

- Disassembling and Cleaning Engine Components

- Replacing and Reinstating: A Step-by-Step Guide

Assessing Engine Damage: What to Look For

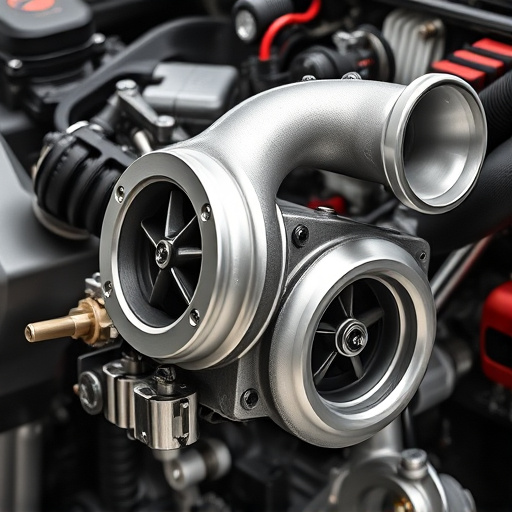

Assessing Engine Damage involves a thorough inspection to identify affected engine components. Look for visible signs such as cracks, deformations, or missing parts. Check for leaks in the oil, coolant, and fuel systems, as these can indicate compromised seals or gaskets. Examine the intake components for damage that could hinder airflow, as well as exhaust tips, which may have suffered impact or wear.

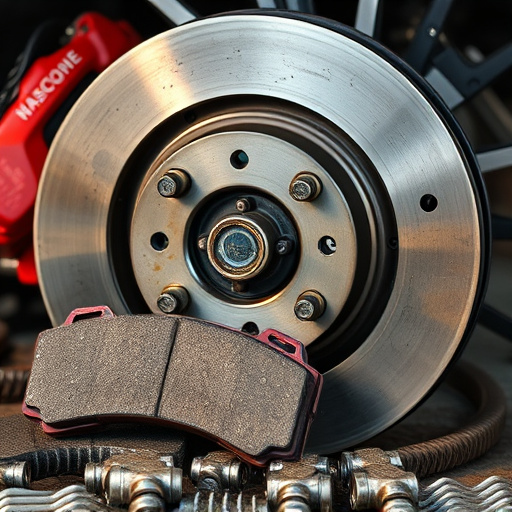

Pay special attention to critical parts like cylinder heads, pistons, and valve trains. Damaged brake rotors can also signal broader issues; inspect them for warping or pitting. Remember, early detection of these problems is crucial for successful rebuilding. By identifying the extent of the damage, you can determine which engine components require replacement or repair, ensuring a more effective and safer rebuild process.

Disassembling and Cleaning Engine Components

After assessing the damage to your engine components, the next crucial step is disassembling and preparing them for reconstruction. This process involves carefully separating each part, taking note of their orientation and connections. It’s essential to have a systematic approach to ensure you can accurately reassemble them later. Start by removing any easily accessible parts like spark plugs, fuel injectors, and air filter kits. These components often require regular replacement and are relatively straightforward to handle.

Once the major pieces are out, move on to disassembling the engine’s inner components. This may include removing cylinder heads, valves, pistons, and even the crankshaft if necessary. Ensure you use appropriate tools and take photos or create detailed notes during this process. Proper cleaning is also vital. Use specialized solvents and brushes to eliminate grease, debris, and any traces of old seals or gaskets. Pay special attention to hard-to-reach areas and crevices, especially when dealing with exhaust tips and cat back exhaust systems. A thorough clean ensures that no contaminants remain, which could impact the performance of new components during reassembly.

Replacing and Reinstating: A Step-by-Step Guide

After assessing the damage to your engine components, the next step is replacing and reinstating them for optimal function. Begin by sourcing high-quality replacements that match the make and model of your vehicle. This ensures compatibility and maintains original performance specifications. When handling parts like cylinder heads, blocks, or pistons, ensure proper cleaning and inspection to remove any debris or damage.

Follow a systematic approach: start with removing the damaged parts carefully, then install new ones, ensuring all gaskets, seals, and connections are secure. For improved engine performance, consider upgrading air filters with high-flow performance air filters and installing cold air intakes to optimize airflow. Once installed, test the engine for any leaks using a pressure gauge and check exhaust systems by examining muffler tips for proper fit and sealing.

Rebuilding engine components after major damage can seem daunting, but with careful assessment, meticulous disassembly, thorough cleaning, and a structured replacement process, it’s achievable. By understanding what to look for in terms of damage, following a systematic disassembly procedure, and adhering to a step-by-step reinstatement guide, you can restore your engine components to like-new condition. Remember, proper disassembly and cleaning are crucial for ensuring the longevity of your repaired parts, ultimately saving you time and money in the long run.