In extreme heat, every automotive part faces increased stress, making understanding environmental conditions crucial for design and upgrades. High-quality performance exhaust systems utilize advanced materials like heat-resistant alloys and specialized coatings to withstand intense thermal loads without compromising efficiency or safety. Key components like high-flow catalytic converters, custom headers, and robust exhaust manifolds decrease backpressure, boosting engine efficiency and power output. Rigorously tested and optimized, these systems deliver peak performance and longevity, addressing interactions with intake components and other critical parts through advanced simulation tools and computer modeling.

In extreme environments characterized by high temperatures, vehicles demand robust exhaust systems to endure intense stress. This article delves into the intricacies of designing a performance exhaust system capable of withstanding such conditions. We explore the key components and design considerations essential for optimal performance and durability. By understanding the demands of high-temperature environments, we provide insights into testing and optimization processes that ensure these systems excel under duress, enhancing both vehicle efficiency and longevity.

- Understanding the Demands of High-Temperature Environments

- Key Components and Design Considerations for a Performance Exhaust System

- Testing and Optimization: Ensuring Optimal Performance and Durability

Understanding the Demands of High-Temperature Environments

In high-temperature environments, every component within a vehicle is pushed to its limits. From engine parts like cylinder heads and block assemblies to sensitive electrical systems and even everyday components such as brake rotors and suspension parts, heat can cause significant stress and deterioration. Thus, understanding these extreme conditions is crucial when designing or upgrading any part of the automotive system. This includes the performance exhaust system, which must withstand elevated temperatures without compromising efficiency or safety.

A well-crafted performance exhaust designed for high-temperature applications incorporates advanced materials and engineering to ensure durability and optimal performance. By utilizing heat-resistant alloys and specialized coatings, these systems can manage intense thermal loads while maintaining structural integrity. This is especially important as the exhaust system acts as a vital component in dissipating engine heat, preventing overheating, and ensuring the overall health of the vehicle under demanding conditions.

Key Components and Design Considerations for a Performance Exhaust System

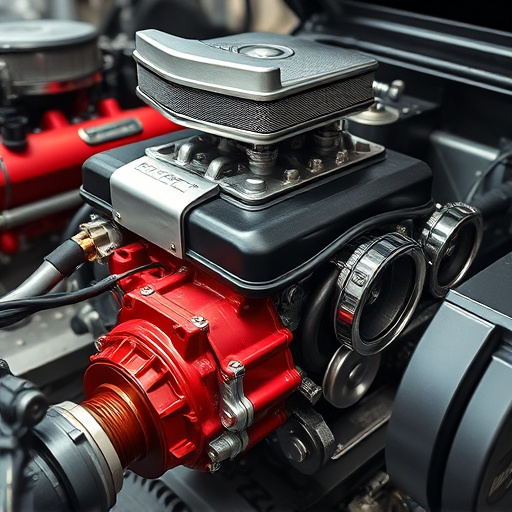

A performance exhaust system is a critical component for high-performance vehicles, designed to handle extreme temperatures and enhance engine efficiency. The key components include high-flow catalytic converters, custom headers, and a robust exhaust manifold. These parts work together to reduce backpressure in the engine, allowing it to breathe better and produce more power.

Design considerations are crucial, focusing on materials that can withstand intense heat and corrosion. Stainless steel is often chosen for its strength and resistance to high temperatures. Additionally, the system must be carefully engineered to manage heat transfer, utilizing strategic cooling points and insulations where necessary. This ensures optimal performance while maintaining the integrity of the exhaust system, even under extreme driving conditions, and complementing advanced performance brakes (like high-spec brake pads or cat-back exhaust systems) for a well-rounded high-performance package.

Testing and Optimization: Ensuring Optimal Performance and Durability

Performance exhaust systems are designed to withstand extreme conditions, from high temperatures to intense pressure. Testing and optimization play a pivotal role in ensuring these systems deliver peak performance and longevity. Rigorous testing protocols simulate real-world scenarios, subjecting the exhaust system to heat, smoke, and varying pressures to mimic demanding driving conditions. This process helps identify any potential weaknesses or areas for improvement.

Engineers use advanced simulation tools and computer modeling to optimize the design, ensuring every component is tailored for efficiency and durability. By carefully examining the interplay between the exhaust system, intake components, and brake rotors (or other critical parts), manufacturers can create a harmonious unit that enhances engine performance while maintaining stability even under harsh conditions. This meticulous approach results in a robust performance exhaust system ready to tackle the most demanding driving environments.

A well-engineered performance exhaust system is indispensable in high-temperature environments, where standard systems may falter. By understanding the unique demands of these conditions, designers can incorporate crucial components and design considerations to create durable and efficient solutions. Thorough testing and optimization ensure that the performance exhaust system not only meets but exceeds expectations, providing a reliable and long-lasting outcome.