Pipe diameters in performance exhaust systems directly affect efficiency and tuning. Wider diameters reduce backpressure, enhance power output for high-performance engines, while smaller diameters maintain consistent pressure differentials with components like coilover kits. Balancing flow restriction, gas velocity, and component compatibility is crucial for optimal engine performance, maximizing horsepower and torque gains, especially in advanced vehicle models.

In the realm of automotive enhancements, a performance exhaust system stands out as a game-changer. Understanding pipe diameter is crucial for optimizing exhaust efficiency and engine performance. This article delves into the intricate relationship between pipe diameter and exhaust dynamics, exploring key factors like flow restrictions and engine responsiveness. By examining these elements, you’ll gain valuable insights into selecting the ideal diameter for your performance exhaust system, ensuring maximum power and efficiency.

- The Role of Pipe Diameter in Exhaust Efficiency

- Factors Influencing Optimal Diameter Selection

- How Pipeline Size Impacts Engine Performance

The Role of Pipe Diameter in Exhaust Efficiency

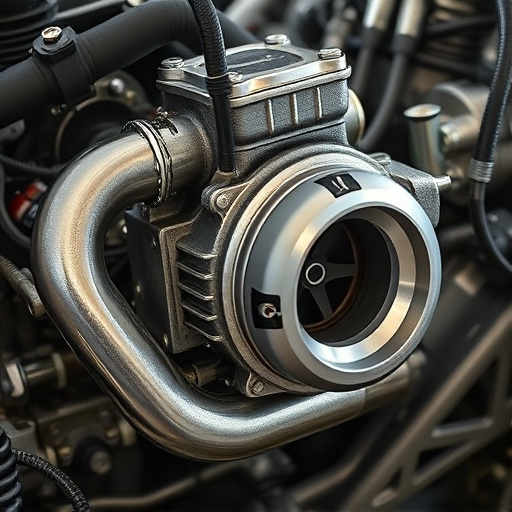

The diameter of pipes in a performance exhaust system plays a pivotal role in determining its overall efficiency and performance. In simple terms, the size of the exhaust pipes influences the flow of gases, which directly impacts the engine’s ability to expel waste products efficiently. A wider pipe diameter allows for smoother and faster gas expulsion, reducing backpressure within the exhaust system. This is particularly beneficial for high-performance engines that demand rapid and efficient gas exchange for optimal power output.

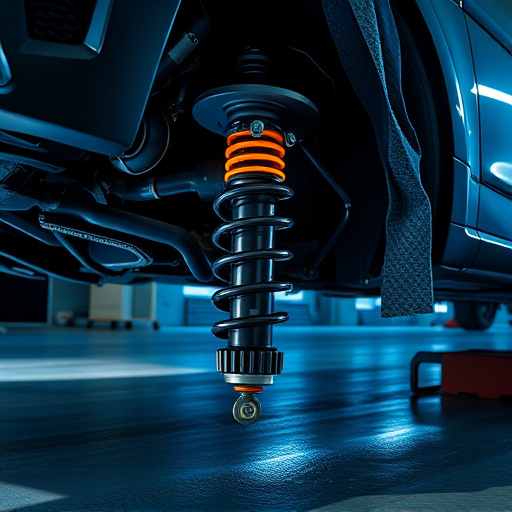

Furthermore, the choice of pipe diameter can also be tied to the overall tuning of the vehicle’s performance. For instance, smaller diameters might be preferred in systems with components like coilover kits or enhanced brake rotors, as they can aid in maintaining a more consistent pressure differential across the exhaust system. Conversely, larger pipes are often used in systems featuring cold air intakes to accommodate higher airflow rates without constriction, ensuring the engine receives ample oxygen for efficient combustion.

Factors Influencing Optimal Diameter Selection

When designing or upgrading a performance exhaust system, selecting the optimal pipe diameter is crucial. Several factors influence this decision, each playing a critical role in achieving desired performance outcomes for high-performance parts. One key consideration is the overall flow restriction within the entire exhaust system, including air intake systems and the specific geometry of the pipes themselves. Wider pipes can enhance gas flow, but they also increase backpressure, which can negatively impact engine power. Therefore, engineers must balance these factors to ensure smooth exhaust gas flow without compromising efficiency.

Another essential aspect is the velocity of gases traveling through the exhaust system. Higher velocities generally favor smaller diameters, as they reduce resistance and allow for faster gas expulsion from the engine. This is particularly important in performance-oriented vehicles where minimizing backpressure contributes significantly to horsepower and torque gains. Additionally, the type of exhaust components, such as headers, mufflers, and catalytic converters, should be considered, as these can dictate specific diameter requirements for optimal performance across the entire range of operating conditions.

How Pipeline Size Impacts Engine Performance

The diameter of a pipeline plays a significant role in determining the efficiency and performance of a vehicle’s exhaust system. In the context of a performance exhaust system, larger pipe diameters can significantly enhance engine performance by allowing for smoother and faster flow of gases. This reduced backpressure enables the engine to expel exhaust gases more efficiently, resulting in increased horsepower and torque. When combined with high-performance brakes, which require well-designed cooling systems, proper pipeline sizing becomes even more critical.

Smaller pipe diameters, on the other hand, can restrict airflow, leading to higher backpressure within the exhaust system. This restriction can cause the engine to work harder to expel gases, ultimately reducing its power output. In contrast, larger pipes facilitate better heat dissipation for performance brakes, ensuring optimal braking performance during prolonged use. Therefore, selecting the right pipe diameter is crucial not just for enhancing the performance exhaust system but also for maintaining the overall efficiency and safety of high-performance vehicles equipped with advanced braking mechanisms.

When optimizing a performance exhaust system, understanding pipe diameter is key. Factors like engine output, RPM range, and gas flow dynamics dictate the ideal size for enhanced exhaust efficiency. By carefully considering these aspects, car enthusiasts can ensure their performance exhaust system delivers superior power and torque, transforming their vehicle’s overall performance.