Lightweight design is crucial for performance exhaust systems, enhancing efficiency, response times, and engine output through strategic material choice and engineering. Advanced materials like titanium and carbon fiber boost strength and temperature resistance, while streamlined shapes reduce air resistance. Future trends include 3D printing for custom components and smart sensors for real-time adjustments, redefining the performance exhaust system landscape.

In today’s race for faster, more efficient vehicles, every component matters. This includes the often-overlooked performance exhaust system. This article explores how lightweight design principles can significantly enhance speed and performance. We delve into the science behind these innovations, highlighting key benefits like reduced weight, improved fuel efficiency, and increased acceleration. Additionally, we examine best practices for implementation and future trends shaping the industry, offering insights vital to automotive engineers and enthusiasts alike.

- Understanding Lightweight Design Principles for Exhaust Systems

- Key Benefits of Lightening Performance Exhaust Components

- Implementing Lightweight Designs: Best Practices and Future Trends

Understanding Lightweight Design Principles for Exhaust Systems

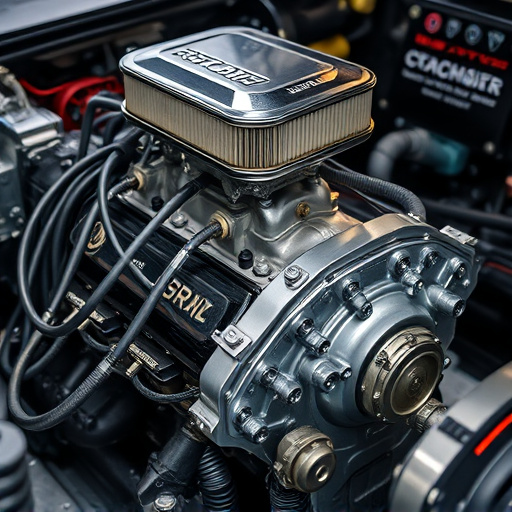

Lightweight design is a key principle in enhancing the performance of exhaust systems. By reducing the overall weight of components, manufacturers can create systems that are faster, more responsive, and efficient. This concept goes beyond simply using lightweight materials like aluminum or carbon fiber; it involves strategic engineering to ensure strength, durability, and optimal airflow. In a performance exhaust system, every gram saved contributes to better engine output and fuel efficiency.

Understanding this design philosophy requires recognizing the interplay between material choices, structural integrity, and aerodynamic flow. For instance, incorporating lightweight high-performance parts, like improved catalytic converters or optimized mufflers, can significantly impact the overall weight reduction. Even components not directly related to performance, such as cold air intakes or brake rotors (though not exhaust system components), can influence the overall system weight, highlighting the need for a holistic approach when applying lightweight design principles.

Key Benefits of Lightening Performance Exhaust Components

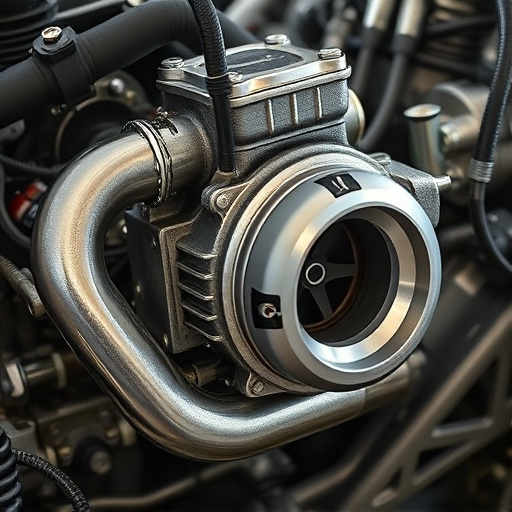

The pursuit of speed in vehicle performance has long been a balancing act between power and weight. Lightweight design plays a pivotal role in enhancing the performance of exhaust systems, offering several key benefits that translate directly into improved vehicle dynamics. By reducing the overall mass of exhaust components, such as headers, mufflers, and catalytic converters, manufacturers can significantly boost the engine’s efficiency.

This strategy not only facilitates faster combustion and increased power output but also improves response times. In a performance exhaust system, lighter components enable quicker discharge of gases, resulting in enhanced breathing capabilities for the engine. Moreover, the weight savings allow for easier handling and acceleration, making these lightweight exhaust systems particularly appealing to enthusiasts seeking both speed and control in their vehicles. The integration of advanced materials and innovative engineering techniques ensures that these benefits are achieved without compromising structural integrity or durability, thereby further enhancing the overall vehicle performance.

Implementing Lightweight Designs: Best Practices and Future Trends

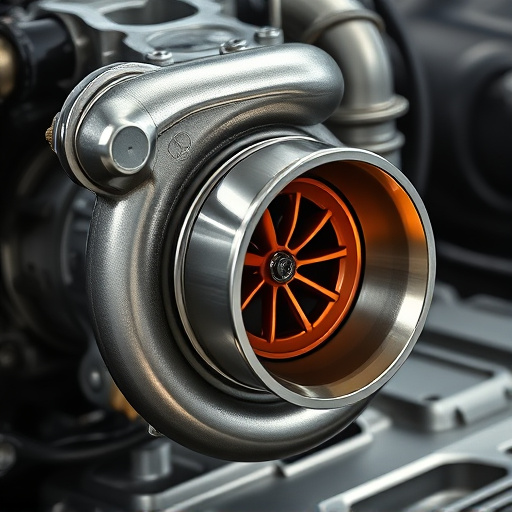

Implementing lightweight designs in performance exhaust systems is a strategy that promises significant improvements in speed and overall vehicle dynamics. Best practices involve utilizing advanced materials like titanium and carbon fiber, which offer superior strength-to-weight ratios while reducing weight significantly. These materials also withstand extreme temperatures, ensuring longevity under demanding conditions. Additionally, designers should focus on streamlined shapes to minimize air resistance, enhancing the engine’s power output.

Future trends suggest an increased adoption of 3D printing technology for custom exhaust components tailored to specific vehicle models and driving styles. This approach allows for intricate designs that optimize gas flow, further boosting performance. Moreover, the integration of smart sensors and advanced electronics could enable real-time adjustments to exhaust settings, enhancing both efficiency and responsiveness, especially in performance brakes and exhaust systems with variable valve timing. These innovations are set to redefine the landscape of high-performance vehicles.

Lightweight design principles have significantly revolutionized the automotive industry, especially in enhancing the performance of exhaust systems. By employing innovative materials and engineering techniques, manufacturers are able to create more efficient, faster, and environmentally friendly vehicles. As technology continues to advance, we can expect even greater integration of these lightweight designs, ultimately driving improvements in fuel efficiency and overall vehicle performance for the benefit of drivers worldwide.