Gas and diesel engines, despite sharing a fundamental purpose, differ significantly in their fuel systems and combustion processes, driven by engine components like carburetors/fuel injectors, spark plugs, high-pressure pumps, and ECUs. These disparities result in varying performance (gas: smoothness & acceleration; diesel: torque & fuel economy), efficiency, and emissions characteristics, influencing their applications in vehicles and machinery. Upgrades like air filters can enhance both types' performance while specific design choices cater to their unique combustion processes and power outputs.

In the realm of automotive engineering, understanding the nuances between gas and diesel engine components is paramount. This article delves into the intricate differences that set these powerplants apart, focusing on the fuel system and combustion processes, engine design variations, and maintenance considerations. From the advanced fuel injection systems in modern engines to the distinct combustion approaches, each type offers unique advantages and challenges. By exploring these aspects, we provide insights into the optimal choices for various applications, empowering automotive enthusiasts and professionals alike.

- Fuel System and Combustion Process

- – Comparison of gas and diesel fuel injection systems

- – Differences in combustion processes: spark ignition vs. compression ignition

Fuel System and Combustion Process

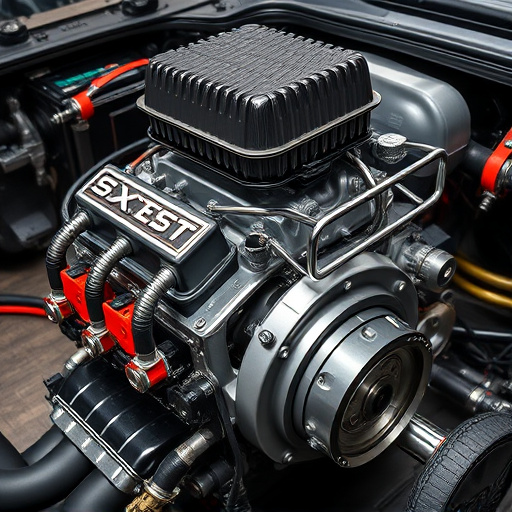

The fuel system is a critical component of both gas and diesel engines, but the mechanism of fuel delivery differs significantly. In gas engines, the fuel system typically involves a carburetor or fuel injectors that mix air and fuel to create the combustion mixture. This mixture is then delivered to the cylinder through an intake manifold, which is connected to the engine’s intake components. In contrast, diesel engines use a high-pressure pump to inject compressed air with a precise amount of fuel, creating a combustion process that relies on heat and pressure alone to ignite the diesel fuel, eliminating the need for a spark plug.

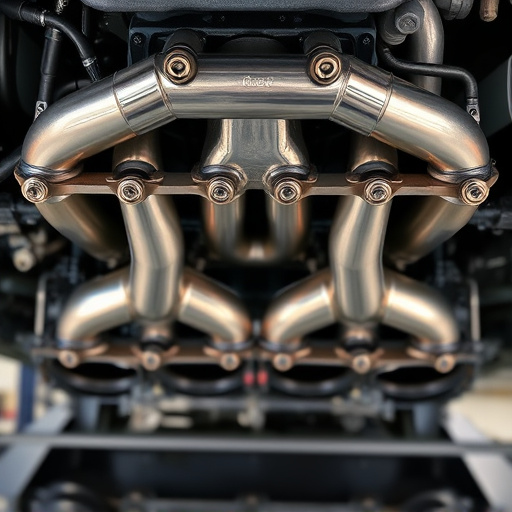

The combustion process varies as well. Gas engines utilize a four-stroke cycle, involving intake, compression, power, and exhaust strokes, while diesel engines use a slightly different approach with intake and compression strokes followed by the power stroke and then exhaust. This difference in engine components affects overall engine performance, efficiency, and emissions output, making each type suitable for different applications and driving conditions. For instance, gas engines often excel in smooth operation and faster acceleration, while diesel engines are renowned for their torque and fuel efficiency, which is why they are prevalent in commercial vehicles and heavy machinery.

– Comparison of gas and diesel fuel injection systems

Gas and diesel engines differ primarily in their fuel injection systems, which play a crucial role in engine performance and efficiency. In gas engines, the fuel injection system is typically more complex due to the need for precise air-fuel ratios. These systems use electronic control units (ECUs) to meter out the exact amount of fuel required, mixed with air from the air intake systems, through fuel injectors. This ensures optimal combustion and enhances engine performance.

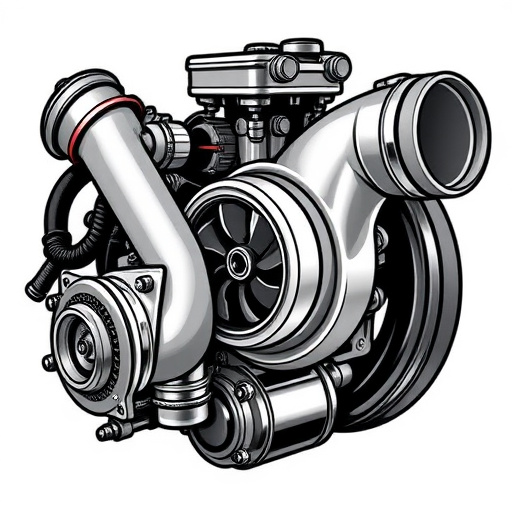

In contrast, diesel engines employ a more direct method. The fuel injection system in diesels is simpler, focusing on high-pressure injection of fuel into the compression chamber. This process, known as direct injection, allows for better control over the combustion process. Upgrading to performance air filters or air filter kits can further enhance air intake systems in both gas and diesel engines, contributing to improved engine components performance and efficiency.

– Differences in combustion processes: spark ignition vs. compression ignition

The combustion process is a fundamental distinction between gas and diesel engines, impacting their overall design and engine components. In gas engines, commonly known as spark-ignition engines, fuel is mixed with air and ignited by a spark plug at a specific time determined by the engine’s timing system. This process requires a precise timing mechanism and often involves more complex intake components to ensure the ideal air-fuel mixture. On the other hand, diesel engines utilize compression ignition, where highly compressed air heats up and ignites diesel fuel injected into the combustion chamber. This method eliminates the need for spark plugs but necessitates stronger engine blocks and pistons due to the immense pressure involved.

This contrasting ignition mechanism also influences the choice of high-performance parts. Diesel engines often require more robust suspension kits to handle the additional strain, whereas gas engines focus on optimizing intake components for efficient air and fuel flow. The combustion process further determines the overall efficiency, power output, and emissions characteristics of these engines, shaping their respective engine component designs and applications in various vehicles.

In understanding the differences between gas and diesel engine components, especially regarding fuel systems and combustion processes, it’s clear that these variations significantly impact performance, efficiency, and maintenance. Gas engines rely on a spark to ignite fuel, featuring injectors for precise timing, while diesel engines utilize compression ignition, relying on high pressure to ignite fuel directly. These distinctions not only affect the choice of engine for specific applications but also inform maintenance strategies, with gas engines generally requiring more frequent fuel system tune-ups and diesel engines presenting unique challenges in exhaust systems. Knowing these differences is crucial for efficient vehicle selection and upkeep, ensuring optimal performance from these essential engine components.