Engine components are vital for a vehicle's smooth operation and safety. Early detection of wear in these complex parts, through visual cues like oil buildup or unusual noises, prevents costly repairs. Advanced diagnostic tools and inspections ensure optimal performance by identifying issues with pistons, valves, and other critical elements. Proactive maintenance extends the engine's lifespan, enhances efficiency, and guarantees vehicle reliability.

Engine components are the backbone of any vehicle’s performance. Spotting wear early is crucial to prevent costly damage. This article guides you through understanding the vital functions of engine components, identifying common signs of wear, and mastering accurate diagnosis techniques using modern tools. Learn how to detect issues proactively, ensuring your engine’s longevity and maintaining optimal efficiency. Discover key indicators and effective strategies for maintaining your vehicle’s most critical elements – the engine components.

- Understanding Engine Components and Their Functions

- Common Signs of Wear in Engine Components

- Accurate Diagnosis: Tools and Techniques for Early Detection

Understanding Engine Components and Their Functions

Engine components are the intricate parts that work together to power your vehicle. Each component plays a vital role in ensuring smooth and efficient engine operation. For instance, the cylinder block houses the cylinders, providing the physical structure for the piston’s movement. The pistons themselves convert the reciprocating motion into rotational force, driving the crankshaft. This, in turn, powers the transmission, and ultimately, the wheels.

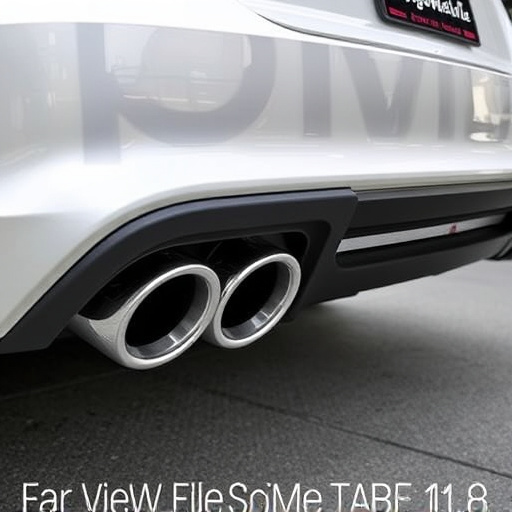

Other essential parts include exhaust mufflers, which silence the engine’s noise and reduce pollutants, and suspension components that absorb road shocks, ensuring a smooth ride. Even brake pads, though seemingly unrelated, are critical for slowing down and stopping the vehicle safely. By understanding these engine components and their functions, drivers can better recognize unusual noises, vibrations, or performance issues that may indicate early signs of wear.

Common Signs of Wear in Engine Components

The early signs of wear in engine components can often go unnoticed, but paying attention to these indicators is crucial for maintaining optimal engine performance and preventing costly repairs. One of the most common visual cues is excessive oil or grease buildup on various parts, such as pistons, valves, and cylinder heads. This may be accompanied by unusual noise during operation, like clicking or knocking sounds, which could point to worn-out bearings or piston rings.

Additionally, leaks from engine components, including those in the suspension system (like shock absorbers), intake components (air filters, hoses), and exhaust systems (muffler tips), should not be ignored. Over time, these leaks can lead to significant performance issues and increased fuel consumption. Regular inspection and prompt action when noting any of these signs are key to ensuring your engine’s longevity and safety.

Accurate Diagnosis: Tools and Techniques for Early Detection

Early detection of wear in engine components is a critical step in maintaining optimal vehicle performance and safety. Accurate diagnosis involves utilizing a combination of sophisticated tools and techniques to identify even the subtlest signs of deterioration. One essential tool for mechanics and car enthusiasts alike is the use of advanced diagnostic scanners that can read and interpret data from sensors embedded within various engine parts, such as pistons, valves, and rotors. These scanners provide real-time feedback on temperature, pressure, and performance metrics, allowing professionals to pinpoint anomalies indicative of potential wear.

Additionally, visual inspections using high-resolution cameras and enhanced lighting can reveal cracks, pitting, or other visible defects in components like exhaust mufflers and performance brakes. While some engine parts are easily accessible for regular checks, others may require specialized tools and expertise to evaluate effectively. Nonetheless, staying proactive with these diagnostic methods enables timely replacement of worn-out high-performance parts, ensuring the longevity and efficiency of your vehicle’s powerplant.

Regularly checking and maintaining your vehicle’s engine components can prevent costly repairs and ensure optimal performance. By understanding the functions of each part and recognizing early signs of wear, such as unusual noises, increased friction, or changes in power output, you can take proactive measures. Utilizing advanced diagnostic tools and techniques discussed in this article will empower car owners to accurately detect wear at its inception, allowing for timely replacement and extending engine lifespan. Staying vigilant with routine maintenance is key to keeping your engine running smoothly.