Understanding OEM (Original Equipment Manufacturer) and aftermarket engine components is crucial in the automotive industry. OEMs offer superior reliability due to precise engineering and unique markings like branding and part numbers. Aftermarket parts provide customization but may vary in quality, requiring careful installation for critical components. Fitment data and compatibility are key when selecting engine components, with aftermarket products needing meticulous research using manufacturer databases.

Identifying original equipment manufacturer (OEM) versus aftermarket engine components is crucial for ensuring optimal performance and reliability. This guide breaks down the process into three key steps. First, understand the distinctions between OEM and aftermarket parts. Next, learn to identify physical attributes that set them apart. Finally, utilize manufacturer and fitment data for accurate determination. By mastering these strategies, you’ll confidently navigate the engine components landscape.

- Understanding OEM and Aftermarket Parts

- Physical Attributes to Look For

- Researching Manufacturer and Fitment Data

Understanding OEM and Aftermarket Parts

In the automotive industry, understanding the distinction between Original Equipment Manufacturer (OEM) and Aftermarket parts is crucial when it comes to engine components. OEM parts are those that are produced by the vehicle manufacturer as original equipment for their specific models. These are the same parts that come installed on new cars straight from the factory. Aftermarket parts, on the other hand, are replacement or add-on pieces made by different manufacturers, designed to fit various makes and models of vehicles. Aftermarket engine components can range from simple upgrades like performance filters to more complex systems such as complete engine kits.

When it comes to reliability and performance, OEM engine components have an edge due to their precise engineering for specific vehicle models. They are built to meet the manufacturer’s standards for quality and compatibility. In contrast, aftermarket parts may vary in terms of quality and fitment, and while they can offer more customization options, they don’t always guarantee the same level of performance or longevity as OEM components. For instance, while aftermarket brake rotors and pads might provide improved braking power for some drivers, not all brands are created equal, and proper installation is essential to ensure safety when it comes to critical parts like brakes.

Physical Attributes to Look For

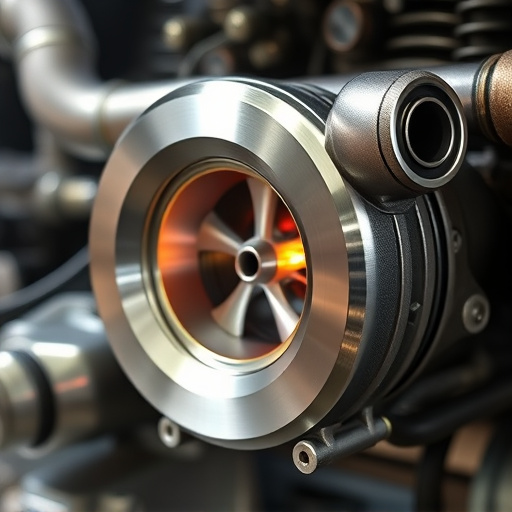

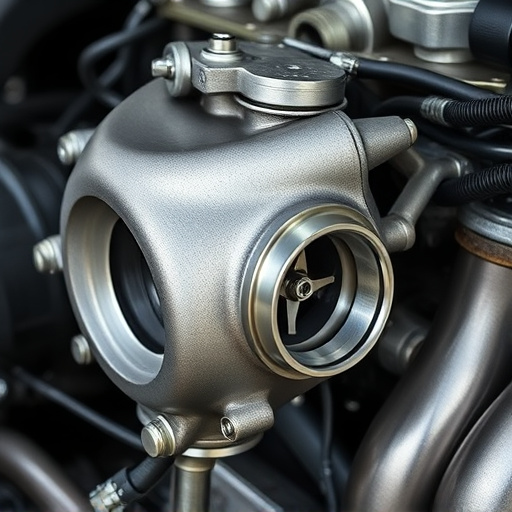

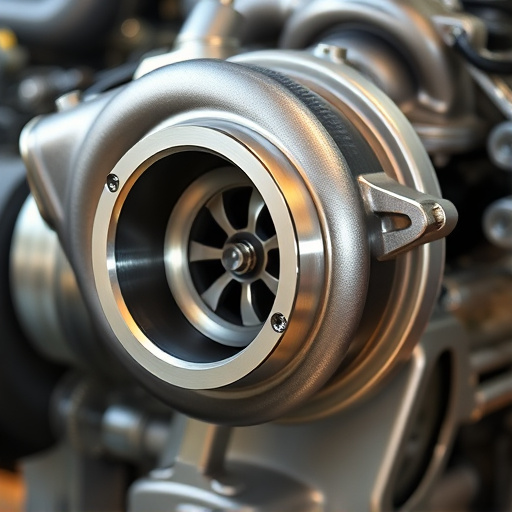

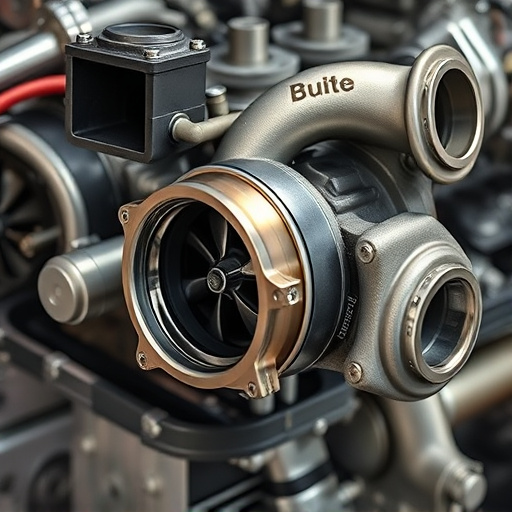

When comparing OEM (Original Equipment Manufacturer) to aftermarket engine components, one of the first things to consider is their physical attributes. OEM parts are designed and manufactured specifically for a particular vehicle model, so they often have unique markings, specifications, and dimensions that set them apart from generic aftermarket alternatives. Look for original branding, part numbers, and serial codes on OEM pieces, which can be found on labels, stamping, or engravings. Aftermarket components, while similar in function, may lack these distinguishing marks and instead feature more generic packaging and labeling.

Additionally, the quality of materials used can provide clues about their origin. OEM parts are typically made from high-grade materials specified by the vehicle manufacturer to ensure durability and performance. Aftermarket items, on the other hand, might use different materials or lower-quality alloys, which could result in visible differences in texture, color, or finish when compared side-by-side with genuine components. For instance, brake rotors (a key component among many) may exhibit variations in thickness, surface treatment, and overall construction between OEM and aftermarket brands. Other physical attributes like the fitment of engine parts, such as cold air intakes, can also indicate their origin, as OEMs usually offer precise, tailored designs while aftermarkets might have more universal or generic fits.

Researching Manufacturer and Fitment Data

When researching engine components, one key differentiator is understanding whether it’s an Original Equipment Manufacturer (OEM) or Aftermarket product. OEM parts are designed and manufactured by the vehicle’s original producer, tailored to specific fitment data for a particular model year and make. This ensures seamless integration and optimal performance. Conversely, aftermarket components are created by independent manufacturers, often with more general specifications, requiring careful consideration during installation to ensure compatibility with your engine.

Accessing manufacturer databases and fitment charts is crucial in this process. Many OEM suppliers offer extensive online resources where you can input your vehicle’s details to retrieve precise information on compatible parts. For exhaust components like tips (exhaust tips) and mufflers (exhaust mufflers), these charts will show exact dimensions, thread sizes, and mounting points, ensuring a direct replacement or proper adaptation. This meticulous research step is vital in distinguishing OEM from aftermarket products, ultimately guiding your decision for the right engine component to suit your needs.

When distinguishing between OEM and aftermarket engine components, a combination of understanding industry terminology, examining physical attributes, and researching manufacturer data is key. By comparing physical characteristics like logos, markings, and design differences, along with verifying fitment and compatibility through manufacturer databases, you can confidently identify the source of any engine component. This knowledge ensures that you’re selecting parts that meet your specific needs, whether they’re original equipment or high-quality aftermarket alternatives.