The digital revolution has profoundly transformed engine components, with computer systems now integral to their design and operation. Historically mechanical and hydraulic, engines now incorporate electronic control units (ECUs) managing fuel injection, spark plugs, and variable valve timing. This digital integration extends to auxiliary systems, real-time monitoring, and adjustments for enhanced efficiency, reduced emissions, and improved vehicle dynamics. Such advancements have significantly boosted engine performance, reliability, and longevity, setting the stage for future innovations in automotive technology.

Computer systems have revolutionized the way modern engines operate, marking a significant evolution from their mechanical predecessors. This article explores the intricate relationship between computer systems and engine components in today’s automotive landscape. We delve into the historical transformation, highlighting the early days of basic control and monitoring to the present, where advanced ECUs (Electronic Control Units) process real-time data for optimal performance. Furthermore, we examine future trends, including AI’s role in diagnostics, IoT applications, and the push towards autonomous vehicles and smart factories, all driven by enhanced engine component integration.

- The Evolution of Engine Components and Computer Integration

- – A historical perspective on engine development and the rise of computerization

- – Early systems: Basic control and monitoring

The Evolution of Engine Components and Computer Integration

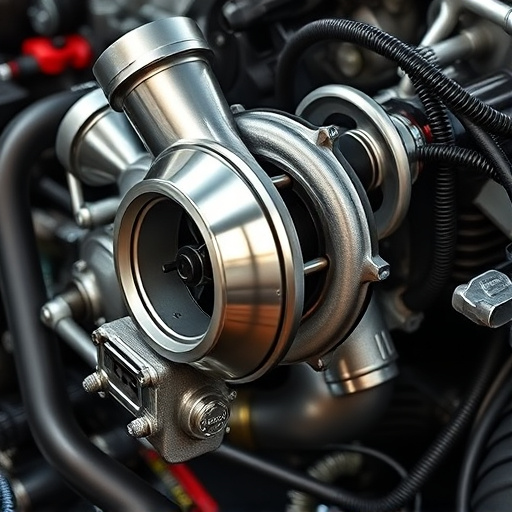

The evolution of engine components has paralleled the digital revolution, with computer systems playing an increasingly integral role in their design and functionality. Historically, engines relied on mechanical and hydraulic systems for control, but the advent of electronic control units (ECUs) marked a significant shift. These ECUs, integrated into modern vehicles, manage various engine components like fuel injectors, spark plugs, and variable valve timing, enabling precise control and optimized performance.

This integration extends beyond core engine operations to auxiliary systems such as air intake systems, exhaust manifolds, and even brake pads and rotors. Computerized sensors monitor engine conditions in real-time, adjusting parameters to ensure efficiency, reduce emissions, and enhance overall vehicle dynamics. This digital interaction has revolutionized not just how engines perform but also their reliability and longevity, setting the stage for future innovations in automotive technology.

– A historical perspective on engine development and the rise of computerization

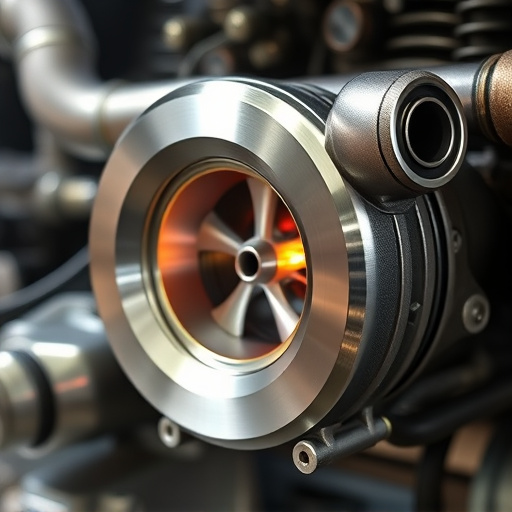

In the past, engine development was largely driven by mechanical principles and intuitive design. Early engines, from the steam-powered wonders to the internal combustion revolution, relied heavily on human expertise and manual adjustments. However, as technology advanced, so did the need for more sophisticated control and precision. The introduction of computerization in the late 20th century marked a significant turning point in engine development. This era witnessed the seamless integration of computer systems with various engine components, leading to unprecedented efficiency and performance gains.

The evolution from purely mechanical systems to computerized ones has been transformative. Today, every aspect of an automobile’s engine can be monitored and adjusted by powerful computing units. From optimizing combustion processes through advanced sensors to managing exhaust systems and enhancing brake components, computer systems have become the backbone of modern engines. Even something as seemingly simple as exhaust tips benefits from this technology, ensuring optimal gas flow and reducing noise pollution. This digital revolution has not only improved engine efficiency but also paved the way for more eco-friendly and innovative solutions in vehicle design.

– Early systems: Basic control and monitoring

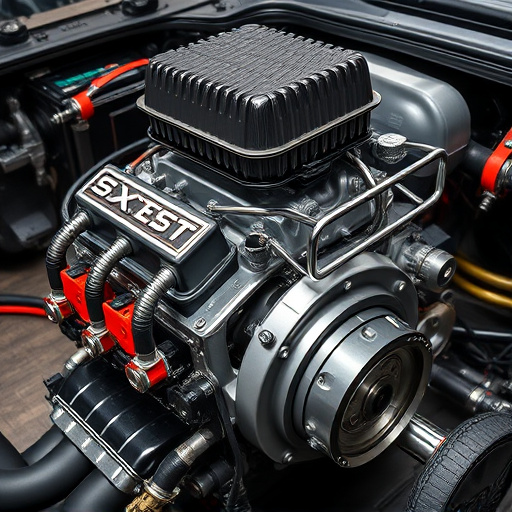

In the early days of automotive technology, computer systems played a minimal role in engine components. These initial systems were primarily focused on basic control and monitoring functions, ensuring smooth operation and driver safety. Computers would collect data from sensors placed throughout the vehicle, such as temperature, pressure, and speed, to adjust fuel injection, ignition timing, and other critical parameters. This basic interaction between computers and engine components laid the foundation for more advanced systems in subsequent years.

As technology advanced, computer systems became integral to various engine components, including suspension and brake rotors. Modern vehicles rely on sophisticated onboard computers to optimize vehicle performance by continuously analyzing data from numerous sensors. These systems not only enhance fuel efficiency and emissions control but also contribute to improved safety features like anti-lock braking systems (ABS) and electronic stability control (ESC), thereby transforming the driving experience and boosting overall vehicle performance.

Computer systems have profoundly transformed how modern engine components interact and function, marking a significant evolution from early basic control and monitoring. Today, advanced computing enables precise real-time data analysis, optimal performance tuning, and predictive maintenance for engine components. This integration enhances efficiency, reduces downtime, and paves the way for more innovative and sustainable automotive technologies. By leveraging computer systems, the future of engine development promises enhanced performance, improved reliability, and a greener environmental impact.