Camshaft design significantly impacts engine components' efficiency and performance by dictating valve timing, enhancing combustion through precise valve opening/closing moments, and facilitating improved airflow/fuel distribution. Valve timing synchronizes operations of pistons, crankshafts, and valves, optimizing power output, torque delivery, and overall efficiency. A well-designed camshaft, paired with optimized intake components and efficient exhaust systems, enhances combustion, maximizes power output, and improves engine breathing.

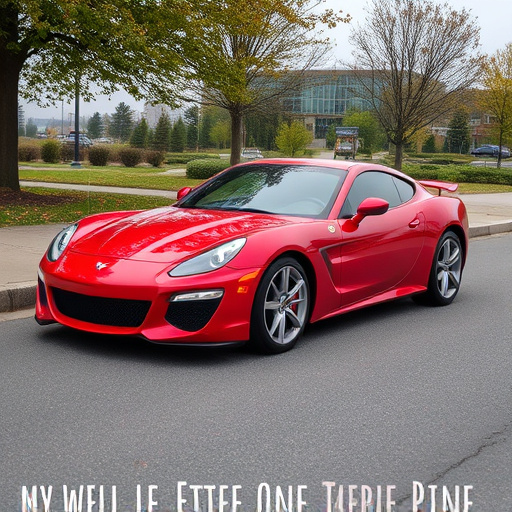

Camshafts, often overlooked, are pivotal in enhancing the performance of various engine components. This article delves into the intricate relationship between camshaft design and overall engine efficiency. We explore how precise valve timing, controlled by the camshaft, synchronizes critical engine parts, optimizing power and torque generation. By understanding these dynamics, engineers can fine-tune engines for enhanced fuel efficiency and increased output, ultimately elevating the performance of every component on the field.

- Camshaft Design Impacts Engine Efficiency

- Valve Timing: Key to Component Synchrony

- Camshaft's Role in Power and Torque Generation

Camshaft Design Impacts Engine Efficiency

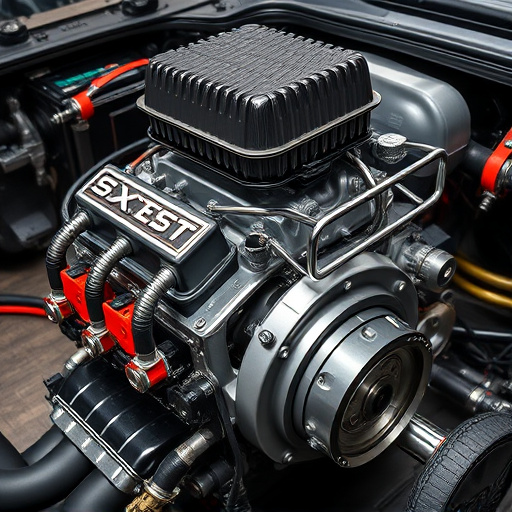

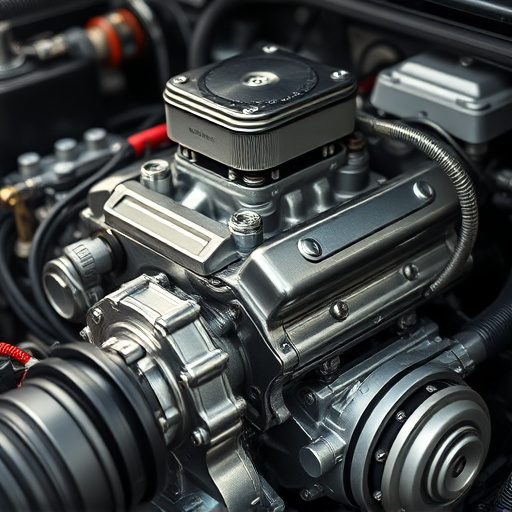

Camshaft design plays a pivotal role in determining the efficiency and overall performance of engine components. The intricate shape and profile of a camshaft directly influence the valve opening and closing timings, which in turn affects the intake and exhaust gas flow within the engine. Optimized camshaft profiles can enhance combustion efficiency by ensuring that valves open at precisely the right moment, allowing for maximum air-fuel mixture entry and effective gas expulsion.

Furthermore, advancements in camshaft design extend beyond standard suspension components to include modifications that cater to high-performance requirements. Cold air intakes and performance air filters, for instance, can work in harmony with carefully engineered camshafts to deliver enhanced power outputs. By facilitating improved airflow and fuel distribution, these components complement the camshaft’s role in optimizing engine performance, ultimately contributing to a more responsive and efficient powerplant.

Valve Timing: Key to Component Synchrony

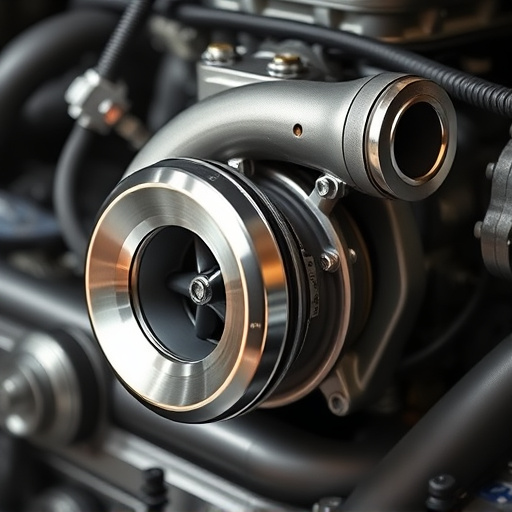

Valve timing plays a pivotal role in ensuring the harmonious synchronization of various engine components. It dictates when valves open and close, controlling the flow of air and fuel into the combustion chamber. This precise timing is crucial for optimal engine performance as it directly influences factors such as power output, torque delivery, and overall efficiency.

In an engine, the camshaft’s interaction with the valve train is instrumental in maintaining a balanced rhythm among different parts, including the piston, crankshaft, and valves. Accurate valve timing ensures that intake and exhaust valves operate in sync with the movement of other components, facilitating efficient combustion and maximizing energy extraction from each cycle. This synchronization is especially critical for modern engines, where advanced suspension kits and high-performance brake components, like precision-engineered brake rotors, demand precise control to unlock their full potential.

Camshaft's Role in Power and Torque Generation

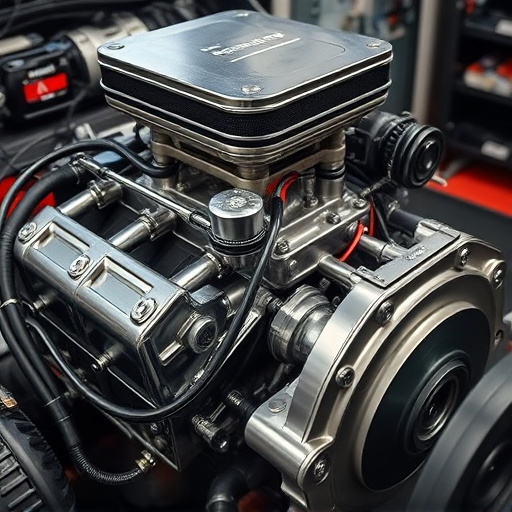

The camshaft, a pivotal component within any internal combustion engine, plays a dynamic role in orchestrating the intricate dance between engine components that results in power and torque generation. Its primary function is to control the timing of the opening and closing of intake and exhaust valves, directly influencing the flow of air and fuel into the cylinder and the subsequent expulsion of exhaust gases. This precise control over valve operation is fundamental to optimizing the engine’s performance across its entire RPM range.

In the context of engine components, a camshaft’s design, including its lobe shape and profile, dictates the lift and duration of the valves, affecting air/fuel mixture intake and exhaust gas discharge. Efficient intake components facilitate the entry of a rich blend of air and fuel, enhancing combustion and maximizing power output. Conversely, well-tuned exhaust systems, often featuring cat back exhaust configurations, ensure seamless evacuation of spent gases, thereby improving engine breathing and further bolstering performance.

In understanding how camshafts influence the performance of engine components, it’s clear that their design directly impacts efficiency. Precise valve timing ensures synchrony among critical engine parts, enhancing power and torque generation. By optimizing camshaft profiles, engineers can significantly improve overall engine performance and efficiency, making them a crucial element in modern automotive engineering.