After significant incidents or repairs, thoroughly inspect engine components like block, crankshaft, camshaft, mufflers, and high-performance parts for damage. Disassemble, clean, document, and assess critical elements like valve springs, piston rings, and gaskets. Replace worn or damaged parts with quality alternatives. Upgrade to performance exhaust, filters, and tips. Follow strict assembly procedures for optimal alignment and prevention of future issues.

After sustaining major damage, rebuilding engine components is a meticulous process requiring careful assessment and expert techniques. This article guides you through the steps of reassembling engine parts, from assessing the extent of damage to implementing best practices for optimal performance. We’ll explore disassembly, cleaning, and advanced rebuilding techniques, ensuring your engine components are restored to their peak condition. Discover how to navigate this intricate process with confidence, leveraging expert insights on engine components.

- Assessing Engine Component Damage: Identifying the Extent

- Disassembly and Cleaning: Preparing for Reconstruction

- Rebuilding Techniques and Best Practices for Optimal Performance

Assessing Engine Component Damage: Identifying the Extent

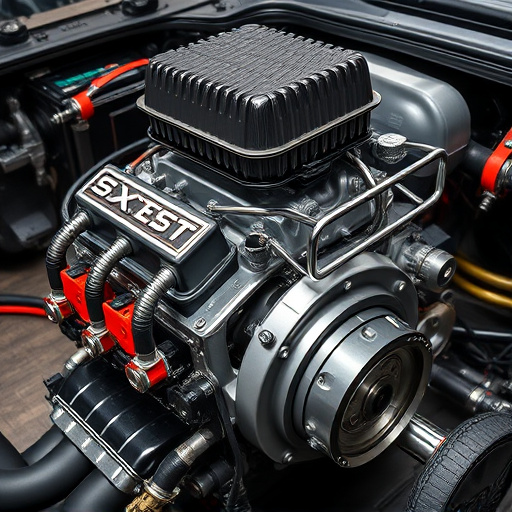

When assessing engine component damage after significant incident or repair, the first step is to thoroughly inspect each part. This involves visually examining for cracks, corrosion, or deformations and running diagnostic tests to gauge their functionality. Engine components like pistons, valves, and cylinder heads are integral to smooth operation, so identifying even the slightest imperfections is crucial.

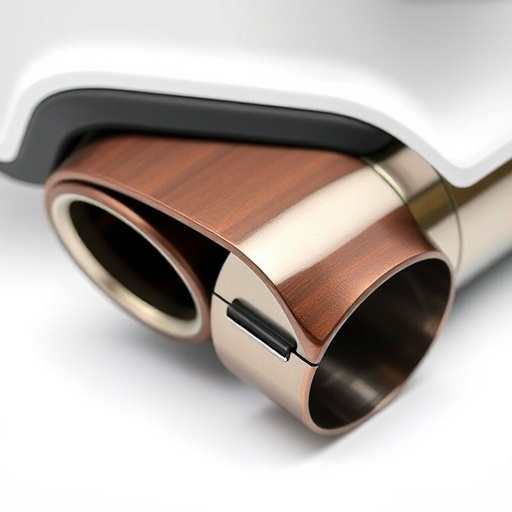

Focus on key areas such as the engine block, which houses the cylinders and crucially connects to other components like the crankshaft and camshaft. Also, check exhaust mufflers, known for accumulating wear and tear over time, as well as high-performance parts that often require specialized attention due to their intricate design. A performance exhaust system, while enhancing engine output, may also be more susceptible to damage in the event of an accident, necessitating meticulous care during the rebuilding process.

Disassembly and Cleaning: Preparing for Reconstruction

Before attempting to rebuild any engine components after significant damage, proper disassembly and cleaning are crucial steps in the process. This initial phase sets the foundation for successful reconstruction and optimal performance. First, carefully disassemble the affected parts, taking note of their original configuration and any specific connections. Ensure that all components are properly documented or photographed to facilitate accurate reassembly later.

Once disassembled, thorough cleaning becomes imperative. Use specialized solvents and brushes to remove any debris, corrosion, or old lubricant residues from the engine components. This meticulous process not only ensures better adhesion for new materials but also helps identify further damage that may have gone unnoticed during initial visual inspections. Moreover, paying attention to intricate details such as valve springs, piston rings, and cylinder head gaskets is vital, especially when considering upgrades like a cat back exhaust or performance exhaust systems, which often necessitate tighter clearances and precise adjustments in the engine’s suspension components.

Rebuilding Techniques and Best Practices for Optimal Performance

When rebuilding engine components after major damage, it’s crucial to employ techniques that ensure optimal performance. The first step is to thoroughly assess and clean the affected areas. This involves removing any debris or remnants of the original damage, which can be achieved through specialized cleaning solutions and tools designed for internal engine work. Once the components are cleaned, inspect them closely for signs of wear, cracks, or deformations that may compromise their integrity.

For best results, consider replacing critical parts such as pistons, valves, and cylinder heads with high-quality, manufacturer-recommended alternatives. Upgrading to performance exhaust systems, high-flow air filter kits, and sleek muffler tips can also significantly enhance engine performance and efficiency. Additionally, ensure that all assembly procedures are followed precisely, using the correct torque specifications for each component. Proper alignment and installation are key to preventing future damage and ensuring a seamless fit.

After carefully disassembling, cleaning, and assessing damaged engine components, it’s now time to focus on reconstruction. Employing meticulous rebuilding techniques and adhering to best practices ensures optimal performance and longevity for your engine. By combining thorough inspection with the right tools and expertise, you can successfully restore engine components, extending their lifespan and enhancing overall efficiency.