Turbo lag, a delay in turbocharger engagement impacting engine performance, is mitigated by efficient intercooler piping. This system swiftly cools compressed air, reducing intake air temperature and enhancing combustion efficiency. Strategic piping layout ensures optimal airflow, swift turbo response, and heat dissipation, preventing overheating during high-load conditions. Well-designed intercooler piping boosts overall vehicle performance, particularly in high-performance cars demanding rapid power delivery, while accommodating upgrades like exhaust systems and coilover kits.

In the realm of turbocharged engines, minimizing turbo lag and optimizing response time is key to enhancing performance. This article delves into the intricate relationship between intercooler piping and engine dynamics. We explore how the layout of intercooler pipes impacts turbo lag, affecting both cooling efficiency and turbine response. By understanding these factors, enthusiasts and professionals can make informed decisions to optimize their vehicles’ power delivery, resulting in a smoother, more responsive driving experience.

- Understanding Turbo Lag and Its Impact on Engine Performance

- The Role of Intercooler Piping in Turbo Response Time

- Optimizing Piping Layout for Efficient Cooling and Quick Turbo Response

Understanding Turbo Lag and Its Impact on Engine Performance

Turbo Lag, a term that sends shivers down every car enthusiast’s spine, refers to the delay between the moment you press the accelerator and when the turbocharger actually engages. This lag can significantly impact engine performance, especially in vehicles equipped with forced induction systems like turbos or superchargers. The primary reason for this phenomenon is the time it takes for compressed air to cool down after being compressed, which reduces the risk of detonation (knocking) and allows for a more efficient combustion cycle.

In the context of intercooler piping layout, understanding how air flows through the system is crucial. Efficient intercooler piping ensures quick cooling of the compressed air, minimizing turbo lag. This, in turn, leads to faster response times, allowing your vehicle’s engine to deliver smoother power delivery and enhanced overall performance, especially when paired with other upgrades like performance exhaust systems or coilover kits.

The Role of Intercooler Piping in Turbo Response Time

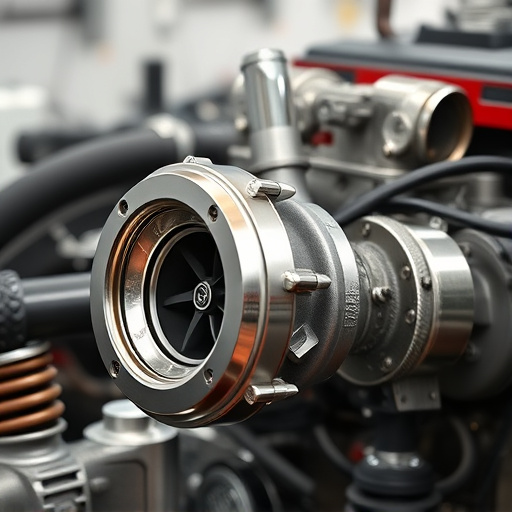

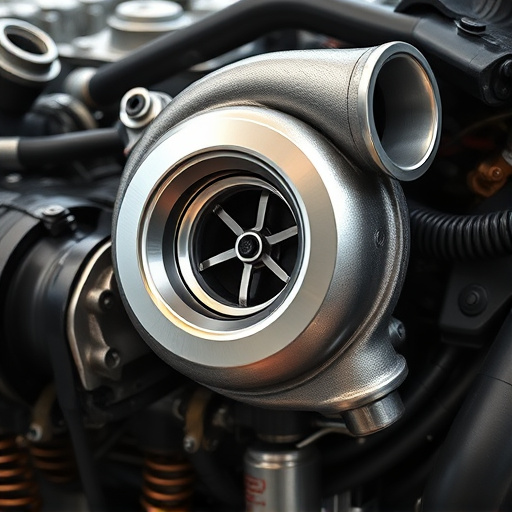

The layout and design of intercooler piping play a significant role in optimizing turbocharger response time. Efficient intercooler piping ensures that compressed air from the turbocharger is quickly and effectively cooled before entering the engine. This rapid cooling process reduces the temperature of the intake air, allowing for denser charge mixing, which enhances combustion efficiency. As a result, the engine can utilize more oxygen, leading to improved power output and reduced turbo lag.

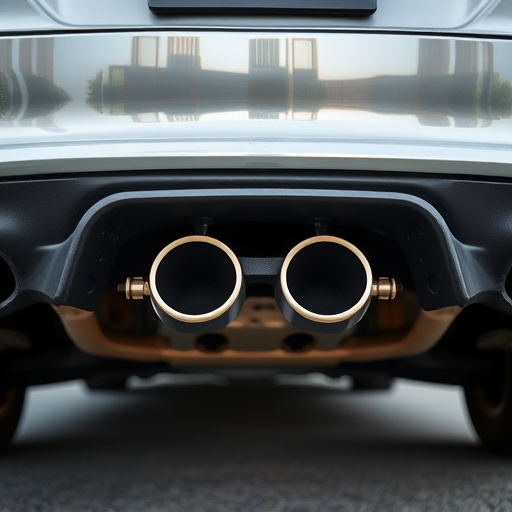

Well-designed intercooler piping also facilitates smoother airflow, minimizing restrictions that could hinder the flow of cool air. This seamless integration ensures that the turbocharger receives a steady stream of cooled air, enabling it to respond swiftly to changes in engine load. Additionally, strategic piping configurations can help dissipate heat more effectively, preventing excessive overheating and ensuring consistent performance, especially during sustained high-load conditions. When combined with high-performance air filters and optimized exhaust systems (including performance exhaust tips), intercooler piping contributes to a well-rounded approach that enhances overall vehicle dynamics and driving experience.

Optimizing Piping Layout for Efficient Cooling and Quick Turbo Response

Optimizing the intercooler piping layout is a key factor in enhancing both cooling efficiency and turbo response time, directly contributing to overall vehicle performance. A well-designed piping system ensures rapid heat transfer from the compressed air to the intercooler core, minimizing temperature rise and reducing turbo lag. This is particularly crucial for high-performance vehicles where quick power delivery is essential for an engaging driving experience.

A strategic approach to intercooler piping involves careful consideration of component placement, bend radii, and overall flow dynamics. Proper routing not only facilitates faster cooling but also allows for more compact packaging, which can be beneficial when upgrading brake components or installing a cat-back exhaust system without compromising performance or reliability.

The layout of intercooler piping plays a significant role in optimizing turbo response time and reducing turbo lag, both crucial factors for enhancing engine performance. By understanding how intercooler design impacts these aspects, car enthusiasts can make informed decisions to fine-tune their vehicles for better overall efficiency. Through strategic optimization, the right intercooler piping layout ensures quick cooling and responsive turbo operation, ultimately enhancing the driving experience.