Modern vehicles boast vastly improved durability and reliability in their engine components thanks to advancements in materials science (like high-strength steels and lightweight alloys), sophisticated manufacturing techniques, and innovative engineering. These developments, driven by a need for better performance and fuel efficiency while meeting stringent emission standards, have transformed engines from fragile early models to robust, long-lasting powerhouses. Components like exhaust systems, air filters, and coilover kits exemplify this progress, enhancing both engine health and overall vehicle longevity.

In today’s automotive landscape, understanding the evolution and future of engine components is crucial. The focus on durability has driven remarkable advancements, ensuring vehicles withstand rigorous conditions. From historical progress to modern innovations like fuel injection systems, each component plays a vital role in overall engine longevity. This article explores these developments, highlighting the top five most durable parts and looking ahead to emerging trends, including lightweight materials, electric vehicle considerations, and predictive maintenance, shaping the future of reliable engine components.

- The Evolution of Engine Durability

- – A brief history of engine development and the focus on durability

- – Key advancements that have led to longer-lasting components

The Evolution of Engine Durability

Over the years, there has been a significant evolution in the durability and reliability of engine components in modern vehicles. Early engines were notorious for their frequent wear and tear, with many parts requiring regular replacement. However, advancements in materials science, manufacturing techniques, and engineering have led to a remarkable increase in the lifespan of these critical components. Today’s automobiles are designed with an emphasis on endurance, incorporating innovative solutions that ensure better performance and longer service life.

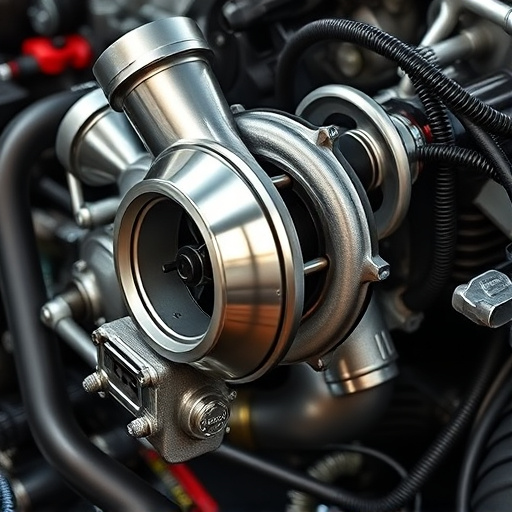

This transformation is evident in various engine components. For instance, modern exhaust systems, complete with high-performance muffler tips, are engineered to withstand extreme temperatures and pressures without compromising structural integrity. Additionally, performance air filters now employ advanced media that trap contaminants effectively, ensuring optimal engine efficiency and reduced degradation over time. Even essential elements like coils springs in coilover kits have seen enhancements, offering improved control, durability, and tuning potential for enthusiasts who demand both performance and longevity.

– A brief history of engine development and the focus on durability

Over the years, engine development has evolved from simple steam-powered mechanisms to complex internal combustion engines we see today. This transformation is a testament to engineers’ relentless pursuit of power and efficiency, while not overlooking durability as a critical factor. Initially, engine components were designed for longevity, focusing on robust materials and sturdy construction to withstand the rigors of daily use. However, with advancements in technology, the industry shifted its gaze towards performance and fuel efficiency, often at the expense of raw durability.

Modern vehicles demand more from their engines, requiring them to deliver peak performance while adhering to stringent emission standards. As a result, engine manufacturers have doubled down on innovation, creating components that offer unparalleled strength and longevity without compromising vehicle performance. This shift is evident in the development of advanced materials like lightweight alloys and high-strength steels, which enhance both durability and fuel efficiency. Moreover, modern engineering techniques ensure precise manufacturing, resulting in improved component reliability, a key aspect in ensuring the long-term health of an engine and, by extension, the entire vehicle. This balance between performance air filters and brake components, along with other critical engine parts, is revolutionizing the driving experience, making vehicles more dependable and environmentally friendly.

– Key advancements that have led to longer-lasting components

In recent years, significant advancements in materials science, manufacturing processes, and design have contributed to the development of more durable engine components. Manufacturers are increasingly utilizing advanced alloys, such as high-strength steels and lightweight aluminum, which offer improved strength-to-weight ratios. These materials can withstand higher temperatures and stresses, prolonging the lifespan of parts like cylinder heads, pistons, and crankshafts.

Moreover, the integration of computer-aided design (CAD) and advanced simulation tools has enabled engineers to optimize engine components for enhanced performance and durability. This precision engineering ensures that every part is tailored for specific functions, reducing wear and tear. For instance, modern brake rotors and suspension kits are designed with sophisticated heat dissipation properties and precise tolerances, respectively, leading to longer service lives compared to traditional counterparts. Additionally, the widespread adoption of high-quality brake pads has significantly reduced maintenance intervals, as these pads offer superior friction control and resist degradation, including in challenging driving conditions.

In today’s modern automotive landscape, the focus on engine durability has evolved significantly, leading to the development of robust and long-lasting engine components. Through advancements in materials science, manufacturing techniques, and design innovations, vehicle engineers have created parts capable of withstanding rigorous driving conditions for extended periods. Understanding the history and key factors contributing to this evolution empowers both manufacturers and consumers to make informed decisions regarding engine component longevity. By continuing to prioritize durability, the automotive industry ensures that vehicles remain reliable and efficient, enhancing the overall driving experience.