Choosing the right DTF Transfer Film is crucial for successful projects, whether for hobbyists or professionals. Key factors include material quality, transparency, and adhesion strength. Vinyl and polycarbonate films offer unique advantages for specific applications like apparel or graphics on phone cases. Informed decisions consider adhesive strength, temperature sensitivity, surface compatibility, and heat press settings. Application-specific requirements like durability, color accuracy, and opacity guide selection. Evaluating film properties, curing processes, and optimal conditions ensures long-lasting results, with online platforms offering a range of options based on size, intended use, and budget.

“Unveiling the intricacies of DTF (Direct-To-Film) transfer films is essential for buyers seeking top-quality printing. This comprehensive guide navigates the complex world of DTF technologies, empowering users to make informed decisions. From understanding fundamental film types to highlighting distinct characteristics and selecting the perfect fit, we demystify the process. Whether you’re a seasoned pro or new to DTF, this article offers valuable insights into choosing the ideal transfer film for your printing needs, ensuring vibrant, accurate results.”

- Understanding DTF Transfer Film Basics: A Buyer's Guide

- Key Differences Between Popular DTF Film Types

- Choosing the Right DTF Transfer Film for Your Needs

Understanding DTF Transfer Film Basics: A Buyer's Guide

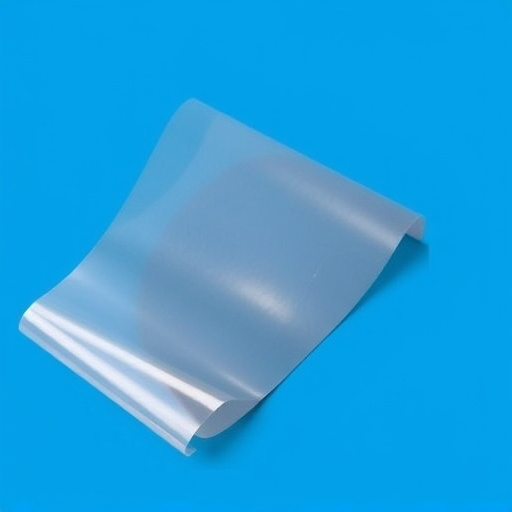

Understanding DTF Transfer Film Basics is a crucial step for buyers looking to dive into direct-to-garment (DTF) printing. These films are essential tools that enable precise and efficient application of designs onto various fabrics. When shopping for DTF Transfer Films, buyers should consider factors like material quality, transparency, and adhesion strength. High-quality films ensure crisp prints with minimal ink transfer to backing paper, making them ideal for both professional printers and hobbyists.

For those seeking options that cater to specific needs, such as dtf fast delivery or handling small orders, the market offers diverse choices. DTF garment printing, in particular, benefits from films designed for clothing applications, which have superior adhesion and heat-resistant properties. Regardless of your requirements, understanding the basics will empower you to make informed decisions when selecting the right DTF Transfer Film for your projects.

Key Differences Between Popular DTF Film Types

When it comes to choosing the right DTF Transfer Film, understanding the key differences between popular types is essential for buyers. Two primary categories dominate the market: vinyl and polycarbonate. Vinyl films are known for their superior durability, making them ideal for long-lasting applications like custom apparel and accessories. They offer excellent color vibrancy and can withstand repeated washing without fading. On the other hand, polycarbonate films stand out for their exceptional clarity and impact resistance. This makes them a preferred choice for high-quality graphics on items like phone cases and automotive components where both visual appeal and durability are paramount.

Additionally, buyers should consider specific design requirements when selecting DTF films. Factors such as adhesive strength, temperature sensitivity, and surface compatibility play crucial roles in ensuring successful transfers. For instance, certain films are optimized for specific heat press settings, with recommended temperatures varying between 300-350°F (149-177°C) depending on the material type. Understanding these nuances will help buyers make informed decisions to achieve the best results when applying DTF transfer films to their products.

Choosing the Right DTF Transfer Film for Your Needs

When selecting a DTF Transfer Film for your project, understanding your specific needs is paramount. Different applications demand varied film properties, from durability and flexibility to color accuracy and opacity. For instance, if you’re involved in short-run, high-quality printing, opt for films designed for precision and vibrant colors. In contrast, industrial applications might require more robust, weather-resistant options.

Consider factors like the size of your transfer, intended use, and budget when making your choice. Online ordering platforms offer a convenient way to explore various DTF films, allowing you to compare specifications easily. Remember that the curing process also plays a role; some films may require specific conditions for optimal adhesion and longevity. For instance, understanding the recommended curing times for your chosen film ensures a successful transfer by size, ensuring long-lasting results for your project.

When selecting a DTF Transfer Film, understanding the nuances between film types is key. By grasping the basics and comparing popular options, buyers can make informed decisions tailored to their specific needs. Remember, the right DTF Transfer Film can significantly enhance your printing experience and outcomes, ensuring precise, high-quality transfers every time.