DTF RIP Software revolutionizes garment printing with advanced Raster Image Processing (RIP), bridging designers and printers for optimal output quality. It offers precise control over image rendering, color management, and curing techniques, enabling print shops to produce intricate designs swiftly and accurately on various materials. This software streamlines workflows through automated plate preparation, batch processing, and support for diverse file formats, enhancing productivity and unlocking new creative potential in DTF printing, ultimately leading to happier customers and high-quality results.

In the print industry, maximizing efficiency is key to staying competitive. Discover how Advanced DTF RIP Software can transform your printing processes. This article delves into the core concepts of Direct To File (DTF) RIP software, exploring its key features and benefits that enhance print quality, speed, and cost-effectiveness. We’ll guide you through implementing this game-changing technology, offering strategies to optimize print efficiency and meet evolving demands in today’s digital era.

- Understanding DTF RIP Software: The Core Concepts

- Key Features and Benefits of Advanced DTF RIP Software

- Implementing DTF RIP Software: Strategies for Optimal Print Efficiency

Understanding DTF RIP Software: The Core Concepts

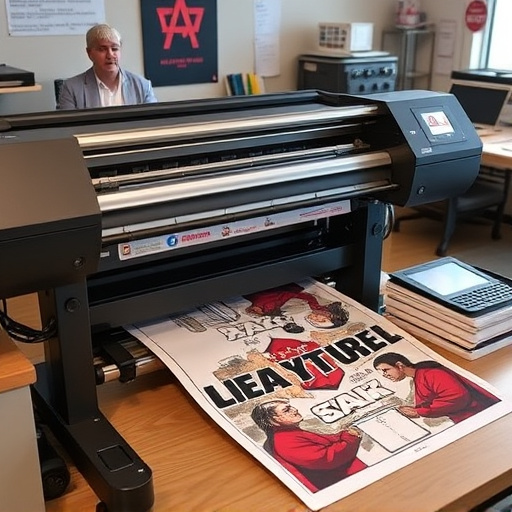

DTF RIP Software is a powerful tool that revolutionizes the print industry, especially in the realm of dtf custom apparel and garment printing. At its core, RIP stands for Raster Image Processing, and it plays a pivotal role in transforming digital designs into printable images. This software acts as an intermediary between the designer’s workflow and the printing equipment, ensuring optimal output quality.

The primary concept revolves around precise control over the printing process. By optimizing image rendering, color management, and cutting-edge curing processes, such as those involved in dtf curing, these programs enhance efficiency. They enable print shops to produce high-quality, intricate designs on various materials, from fabric to vinyl, with speed and accuracy. This not only improves productivity but also opens up new possibilities for creative expression in the world of DTF (Direct-To-Fabric) printing.

Key Features and Benefits of Advanced DTF RIP Software

Advanced DTF RIP software is a game-changer for print businesses aiming to boost efficiency and deliver high-quality results. Its key features include intelligent color management, which ensures precise and consistent color reproduction across various print mediums. This precision is vital for achieving stunning visuals in final products, especially when dealing with complex DTG custom orders.

Moreover, these software solutions offer automated plate preparation, simplifying the curing process and reducing setup times significantly. By streamlining the workflow from design to printing, businesses can accommodate more dtf custom orders without compromising quality. The result is a faster turnaround time, increased productivity, and ultimately, happier customers receiving high-quality dtf transfers.

Implementing DTF RIP Software: Strategies for Optimal Print Efficiency

Implementing DTF RIP (Digital Transfer File) Software is a strategic move to optimize print efficiency for businesses dealing with bulk orders and custom transfers. This advanced technology streamlines the process, from designing to printing, ensuring precision and speed. By using DTF software, printers can pre-process designs, automatically generating the necessary files for DTG or heat transfer applications. This preparation reduces setup time significantly, allowing for faster turnaround of dtf bulk orders and dtf transfers ready to press.

For maximum efficiency, it’s crucial to choose a DTF RIP Software that supports various file formats, offers robust color management tools, and includes automated layout features. These capabilities ensure that intricate designs with fine details are accurately reproduced on various print surfaces, be it fabric, paper, or other materials used in dtf heat transfers. The software should also facilitate batch processing, enabling printers to manage multiple jobs simultaneously, further enhancing productivity.

DTF RIP software is a game-changer in print efficiency, offering advanced features that streamline production and enhance quality. By understanding its core concepts and implementing strategic solutions, businesses can maximize their printing capabilities. With these tools, navigating the complex world of digital to film (DTF) ripping becomes manageable, ensuring optimal results for any printing task. Embrace this technology to revolutionize your print workflow and stay ahead in today’s competitive market.