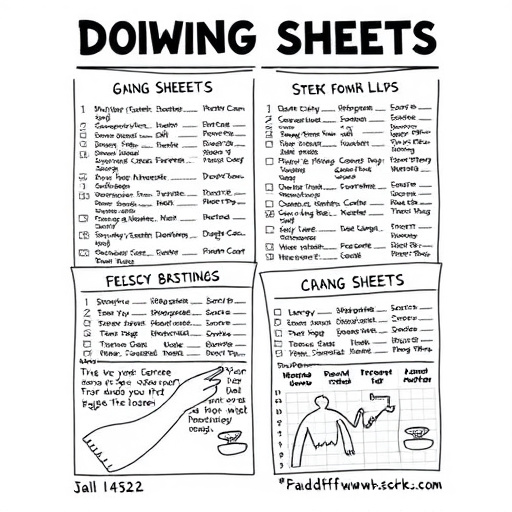

Choosing the right fabric is crucial for DTF shirt printing quality and durability. While cotton is popular, its smooth surface requires specific settings. Opt for polyester or blended fabrics for better design adhesion and long-lasting prints. Consider fabric weight, texture, and heat press settings to avoid mistakes and achieve professional results, ensuring vibrant designs with your DTF gang sheet builder.

“Avoid common pitfalls in Direct-To-Fabric (DTF) shirt printing to ensure professional, high-quality results. This guide highlights critical areas often overlooked: choosing the right fabric, understanding material science for optimal print adherence and durability; designing with pixel-perfect resolution to prevent blurry or pixelated images; and meticulous pre-press preparation to guarantee precise design placement and color accuracy. Mastering these aspects will elevate your DTF printing game, ensuring satisfied customers.”

- Choosing the Wrong Fabric

- – Understanding fabric types and their suitability for DTF printing

- – Factors to consider: material, weight, color, and stretch

Choosing the Wrong Fabric

Choosing the right fabric is a crucial step in DTF shirt printing, as it directly impacts the final product’s quality and durability. Many beginners make the mistake of selecting fabrics that are not suitable for direct-to-fabric (DTF) methods. Cotton, for instance, while popular, can be challenging to print on due to its smooth surface, requiring specific settings and preparation. Instead, opt for materials like polyester or a blend, which offer better adhesion for your dtf design transfers. These fabrics provide a smoother base, ensuring your designs are crisp and long-lasting.

Remember, when uploading your own gang sheet for DTF printing, consider the fabric’s weight and texture. Different settings on your heat press machine will be required for various materials, so it’s essential to understand the dtf heat press settings for optimal results. Taking the time to research and choose the appropriate fabric can save you from potential mistakes and ensure your printed shirts look as intended.

– Understanding fabric types and their suitability for DTF printing

When it comes to DTF shirt printing, choosing the right fabric is key to achieving high-quality results. Different fabrics have varying properties that can impact how well they adhere to the printing process, ultimately affecting the final product. For instance, natural fibers like cotton and linen are popular choices for DTF printing due to their absorbency and ability to hold ink effectively. Synthetic materials, such as polyester and nylon, also work well but may require specific types of dtf transfer film to ensure optimal adhesion.

Understanding the dtf printing process involves knowing that direct-to-film transfers rely on precise temperature and pressure settings during application. Not all fabrics are created equal in this regard, so it’s crucial to select a material suitable for your chosen dtf transfer film. For best results, consider the fabric’s weight, texture, and composition when planning your DTF shirt printing project. This ensures that the intricate details of your design are accurately reproduced, creating a professional and vibrant final product.

– Factors to consider: material, weight, color, and stretch

When it comes to DTF shirt printing, selecting the right material is a crucial step. The fabric’s composition and weight directly impact the final print quality and wearer comfort. Opting for high-quality materials like cotton or polyester blends ensures a smoother surface for printing. For instance, a 100% ring-spun cotton t-shirt provides an excellent canvas for detailed designs, while a lighter fabric might require careful consideration to avoid visible streaks during the DTF curing process.

Color choice is another vital aspect. Different fabrics have varying capabilities to absorb ink. Lighter colors reflect more light, making it easier for vibrant inks to showcase their richness. Dark hues can be challenging as they may require additional layers or specialized inks. Additionally, stretching properties should be evaluated, especially for activewear. Stretchy fabrics demand specific printing techniques to maintain design integrity during movement, ensuring your DTF custom apparel retains its visual appeal even under stress. Utilizing the right material, color, and stretch combination will set the stage for impeccable print results with your DTF gang sheet builder.

When it comes to DTF shirt printing, avoiding common mistakes is key to achieving high-quality results. By understanding fabric types and their suitability for DTF printing, as well as considering material, weight, color, and stretch, you can ensure your prints are vibrant and long-lasting. Remember, the right fabric choice is fundamental to delivering exceptional custom shirts that meet customer expectations.