Boat wrap installation is a professional process using durable vinyl materials like 3M or Avery to protect and enhance a boat's exterior, offering UV protection, fading prevention, and aesthetic customization through various colors, patterns, and graphic designs. This meticulous process involves precise surface preparation, priming, tailored vinyl application, and regular maintenance including cleaning, UV protection with wax/sealant, routine inspections, and prompt repair using premium automotive services to preserve the wrap's beauty and integrity over time.

“Elevate your boat’s style and protection with a professional boat wrap installation using top-tier 3M or Avery vinyl. This comprehensive guide delves into the process, materials, and benefits of this innovative technique. Learn how high-quality wraps enhance durability, offer easy maintenance, and provide a sleek, customizable exterior. Discover the step-by-step application process, essential tips for longevity, and expert advice on choosing the right materials. Optimize your boat’s look and performance with our insightful guide on boat wrap installation.”

- Understanding Boat Wrap Installation: Materials and Benefits

- The Process of Applying High-Quality 3M or Avery Vinyl Wraps

- Maintaining Your Boat Wrap: Tips for Longevity and Protection

Understanding Boat Wrap Installation: Materials and Benefits

Understanding Boat Wrap Installation: Materials and Benefits

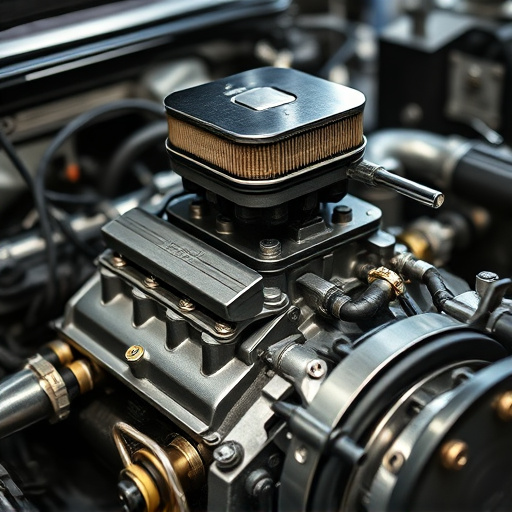

Boat wrap installation is a process that involves applying high-quality vinyl materials to the exterior surface of a boat, offering numerous benefits. The primary material used in this process is 3M or Avery vinyl, renowned for its superior durability and vibrant finish. These protective coatings not only safeguard the boat’s surface from UV damage and fading but also enhance its overall aesthetic appeal. The installation process involves precise cutting and application techniques to ensure a seamless fit, much like custom vehicle wraps.

Additionally, boat wrap installation can incorporate window tinting for enhanced privacy and heat reduction inside the boat. This feature is particularly valuable in regions with intense sunlight. The versatility of this technique allows for customization, enabling owners to choose from a range of colors, patterns, or even graphic designs to personalize their vessel. Thus, boat wrap installation isn’t just about protection; it’s also about transforming your boat into a unique, stylish reflection of your taste and lifestyle.

The Process of Applying High-Quality 3M or Avery Vinyl Wraps

The process of applying high-quality 3M or Avery vinyl wraps to boats involves several meticulous steps for a professional finish. It begins with thorough preparation of the boat’s surface, ensuring it’s clean, dry, and free from any debris. Priming the surface is crucial to enhance adhesion, followed by careful measurement and cutting of the vinyl wrap to fit the contours of the boat.

Once cut, the vinyl wraps are carefully positioned and smoothly applied, eliminating any air bubbles or wrinkles. This meticulous installation process ensures not only a visually appealing boat wrap but also provides excellent UV protection, safeguarding the boat’s finish from the harsh effects of sunlight. The end result is a stunning transformation that enhances the boat’s aesthetics, offering an effective car customization solution for owners seeking to personalize their vessels.

Maintaining Your Boat Wrap: Tips for Longevity and Protection

A successful boat wrap installation is only half the battle; maintaining your new protective layer is key to ensuring its longevity and keeping your boat looking its best. Regular cleaning and inspection are essential components of any boat wrap care routine. Start by washing your boat wrap with a mild, pH-balanced soap and warm water to remove dirt, salt, and other debris that can damage the material. Avoid using abrasive cleaners or scrub brushes, as they may scuff or scratch the surface.

Protecting your vinyl wrap from UV exposure is another critical aspect of maintenance. Applying a high-quality wax or sealant every few months will create a barrier against harmful rays, preventing fading and cracking. Additionally, consider parking your boat in shaded areas when possible to reduce direct sunlight exposure. For optimal results, combine these care tips with regular checks for any signs of damage or wear, ensuring you address issues promptly using premium automotive services and the right repair techniques for vinyl wraps. This proactive approach will help preserve the beauty and integrity of your boat wrap installation over time.

Boat wrap installation is a transformative process that not only enhances the aesthetics of your vessel but also offers significant protection. Using high-quality 3M or Avery vinyl wraps, as discussed in this article, ensures longevity and easy maintenance. By following the detailed steps outlined for application and the provided tips for upkeep, you can enjoy a pristine boat wrap that stands out on the water. Remember, proper installation and regular care are key to maximizing the benefits of this investment in your boat’s protection and style.