DTF inks (Direct to Fabric) are transforming the printing industry with their innovative approach to custom garment printing. Offering faster, more efficient, and eco-friendly production compared to traditional methods, these inks provide vibrant colors and high-quality prints on various fabrics. With precise heat press settings, DTF inks ensure intricate designs that meet superior quality and durability standards, catering to the growing demand for quick turnaround times. Ideal for labels, packaging, posters, and banners, DTF inks empower designers to bring their creative visions to life effortlessly while accommodating both small and large orders in the textile industry.

“The printing industry is witnessing a significant shift with Direct to Film (DTF) inks taking center stage at global conventions. This innovative technology promises to revolutionize traditional printing methods, as evidenced by its growing presence at key industry events. In this article, we explore the benefits and unique characteristics of DTF inks, their potential impact on various sectors, and how they are poised to become game-changers in the world of printing.”

- The Rise of DTF Inks in the Printing Industry

- – Exploring the benefits and advancements of DTF (Direct to Film) inks

- – How they differ from traditional printing methods

The Rise of DTF Inks in the Printing Industry

The printing industry has witnessed a significant evolution with the advent of Direct to Fabric (DTF) inks, transforming the way garments and textiles are designed and produced. This cutting-edge technology has revolutionized custom dtf transfers, enabling faster, more efficient, and environmentally friendly printing processes. DTF inks offer an alternative to traditional methods by eliminating the need for elaborate set-up procedures, thereby reducing production time and costs.

With their superior color vibrancy and ability to produce high-quality prints on a variety of fabrics, DTF inks have quickly gained popularity among printers worldwide. The demand for dtf fast delivery has surged, as businesses and designers alike recognize the benefits of this modern printing technique. Moreover, precise control over heat press settings allows for intricate designs and detailed visuals, ensuring that every custom dtf transfer meets the highest standards of quality and durability.

– Exploring the benefits and advancements of DTF (Direct to Film) inks

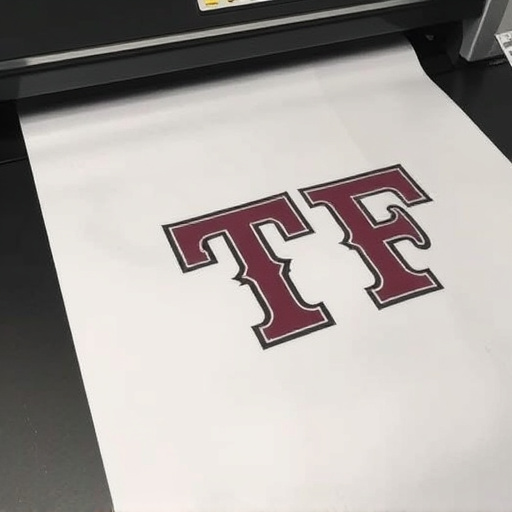

Direct to Film (DTF) inks are revolutionizing the printing industry, offering a game-changer for professionals seeking high-quality, vibrant designs. This cutting-edge technology eliminates the need for traditional plates, resulting in faster production times and enhanced efficiency. With DTF inks, printers can achieve remarkable detail and accuracy, ensuring every design comes to life with stunning clarity.

One of the key advantages is its versatility; DTF gang sheet builders enable the printing of various materials, from labels and packaging to posters and banners, all with consistent print quality. This advancement not only simplifies the production process but also opens up a world of creative possibilities for designers, allowing them to bring intricate and bold visuals to life with ease.

– How they differ from traditional printing methods

Direct to fabric (DTF) printing inks are transforming the textile industry by offering a modern alternative to traditional methods. Unlike conventional techniques that often involve multiple steps and specialized equipment, DTF inks provide a straightforward approach to printing on various fabrics. This method allows for direct application of ink onto the fabric’s surface, eliminating the need for intermediate layers or coatings.

One of the key differences lies in their durability and versatility. DTF inks are designed to withstand rigorous washing and drying processes, ensuring that artwork transfers to fabrics last longer and maintain their vibrancy. This makes them ideal for creating durable clothing, accessories, and home textiles with eye-catching designs. Moreover, DTF printing accommodates both small and large orders, catering to a wide range of businesses and individual artists looking to bring their creative visions to life efficiently and cost-effectively.

DTF inks are poised to transform the printing industry, offering precise color reproduction, faster production times, and reduced waste. As global printing conventions highlight these advancements, it’s clear that DTF technology is a game-changer, revolutionizing how we create and share visual content. Its growing popularity signals an exciting future for print media.