Turbo heat shields are crucial components for turbocharged vehicles, protecting against excessive heat that can harm performance and cause damage. The best shields utilize advanced materials like stainless steel, aluminum alloys, or composite options, offering superior protection and contributing to improved vehicle reliability and overall performance. Selection should consider compatibility with suspension/coilover kits, air intake systems, and exhaust setups, ensuring optimal airflow and cooling. Proper placement, regular maintenance, and timely replacement extend the turbocharger's lifespan, enhance engine cooling, boost power output, and improve fuel efficiency.

Choosing the best turbo heat shield is crucial for optimizing your engine’s performance. This essential component manages exhaust gases, reduces backpressure, and enhances turbine efficiency. In this guide, we’ll explore the role of turbo heat shields, their materials, and the numerous benefits they offer. We’ll also walk you through critical factors to consider during selection, along with expert tips for installation and maintenance to ensure peak performance from your turbo setup.

- Understanding Turbo Heat Shields: Materials and Benefits

- Factors to Consider When Choosing a Turbo Heat Shield

- Installation and Maintenance Tips for Optimal Performance

Understanding Turbo Heat Shields: Materials and Benefits

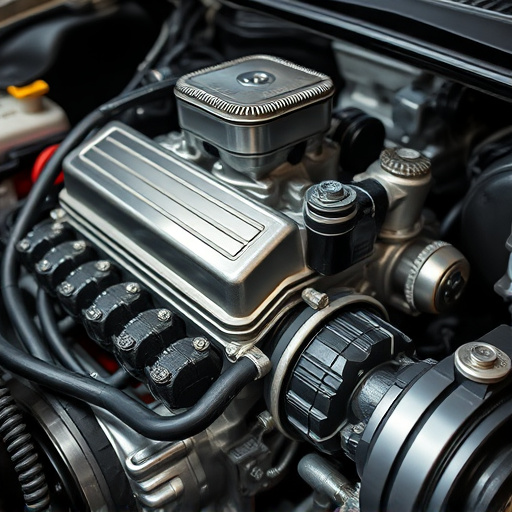

Turbo heat shields are an essential component for any vehicle with a turbocharged engine. These protective barriers serve as a crucial line of defense against the extreme heat generated by turbochargers, which can lead to serious performance issues and even damage if not properly managed. Understanding the materials used in their construction is key to selecting the best shield for your setup.

High-quality turbo heat shields are typically crafted from advanced materials designed to withstand intense temperatures while also offering excellent durability and heat dissipation properties. Stainless steel, for instance, is a popular choice due to its resistance to corrosion and ability to efficiently transfer heat away from the engine bay. Other options include aluminum alloys known for their lightweight nature and efficient thermal conductivity, making them ideal for those seeking both performance and reduced weight in their exhaust systems. Moreover, advanced composite materials are increasingly being used, offering superior strength-to-weight ratios and excellent heat resistance, particularly beneficial when integrated with high-performance parts. By carefully considering these factors, you can choose a turbo heat shield that not only protects your engine but also contributes to the overall performance and reliability of your vehicle’s critical components, including brake components.

Factors to Consider When Choosing a Turbo Heat Shield

When selecting a turbo heat shield, several key factors come into play to ensure it aligns with your vehicle’s setup and performance needs. One of the primary considerations is compatibility; the shield must fit seamlessly with your existing suspension kits or coilover kits without compromising their functionality. This ensures optimal air flow around critical components, maintaining the integrity of your vehicle’s cooling system.

Additionally, materials play a significant role in performance. High-quality heat shields made from durable, heat-resistant alloys can withstand extreme temperatures and offer longer lifespans. Consider also how well the shield integrates with your vehicle’s aesthetics, especially if you have a custom air intake system, ensuring it complements your setup rather than clashing with its design.

Installation and Maintenance Tips for Optimal Performance

When installing a turbo heat shield, proper placement is key to ensure optimal performance. Follow the manufacturer’s instructions carefully, as incorrect positioning can lead to reduced efficiency and even damage to your vehicle’s components. Secure the shield tightly using the recommended hardware to prevent shifting or movement during operation. Regular maintenance is equally important; inspect the heat shield for any signs of damage, corrosion, or loose connections. Clean it thoroughly to remove dirt, grease, or debris that could impede airflow. Replacing worn-out parts or damaged shields promptly will ensure your turbocharger operates at peak condition.

Consider the compatibility of the heat shield with your specific exhaust systems and air filter kits for seamless integration. High-performance parts require meticulous care; a well-maintained turbo heat shield can contribute to better engine cooling, increased power output, and improved fuel efficiency. Remember, a properly installed and maintained shield is crucial for sustaining the performance and longevity of your vehicle’s turbocharger and overall exhaust system.

When selecting a turbo heat shield, understanding your vehicle’s specific needs is key. By considering factors like material, size, and compatibility, you can ensure optimal performance and longevity. With proper installation and regular maintenance, the right turbo heat shield will not only protect your engine but also enhance overall efficiency, making it an essential accessory for any turbocharged setup.