Mass Air Flow (MAF) Sensors are critical components in tuned engines, regulating fuel injection and ignition timing by measuring airflow rate. Calibration is essential for accurate readings, especially in modified vehicles with coilover kits. The process involves disconnecting the sensor, simulating various airflow conditions, and comparing outputs to known values. Regular calibration, every 50-100k miles, along with clean intake components, proper wiring, and balanced air/fuel ratio, ensures optimal engine performance. Consult manufacturer guidelines for accurate MAF sensor calibration.

“Unleash your tuned engine’s full potential with a precise Mass Air Flow Sensor (MAFS) calibration. This critical component ensures optimal fuel-air mixture, enhancing performance and efficiency. In this guide, we’ll demystify MAFS calibration, walking you through the process step-by-step. From understanding these sensors to mastering best practices, you’ll gain the knowledge needed to maintain peak engine performance. Keep your vehicle humming harmoniously with our expert tips on MAFS calibration.”

- Understanding Mass Air Flow Sensors: Their Role in Tuned Engines

- Calibration Process: Steps to Ensure Precise Readings

- Tips for Maintaining Optimal Performance: Precautions and Best Practices

Understanding Mass Air Flow Sensors: Their Role in Tuned Engines

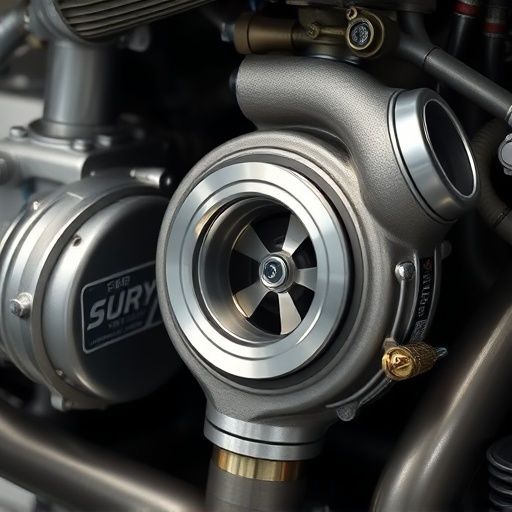

Mass Air Flow (MAF) Sensors are a critical component in tuned engines, playing a pivotal role in ensuring optimal vehicle performance. They measure the mass flow rate of air entering the engine, providing essential data to the engine control unit (ECU). This information is crucial for accurate fuel injection and ignition timing, which directly impacts engine efficiency and power output. In tuned vehicles, where performance modifications like coilover kits are often installed, precise MAF sensor calibration becomes even more vital.

These sensors are typically located in the air intake system, close to the engine’s air filter. They monitor the volume of air entering the engine, taking into account various environmental factors like temperature and humidity. By accurately calibrating the MAF sensor, you ensure that the ECU receives precise data, enabling it to fine-tune fuel delivery and ignition timing accordingly. This, in turn, enhances overall vehicle performance and contributes to a smoother, more responsive driving experience.

Calibration Process: Steps to Ensure Precise Readings

The calibration process for a mass air flow (MAF) sensor is a critical step in ensuring precise readings and optimal engine performance. To start, disconnect the sensor from the vehicle’s electrical system to prevent any interference. Next, use specialized tools to simulate various air flow conditions, typically by adjusting the intake air temperature and pressure. This involves carefully controlling the environment around the sensor to mimic different driving scenarios.

As you adjust these parameters, observe the sensor’s output closely, comparing its readings against known values from a calibrated reference. Each step must be precise and systematic to avoid errors. You may also need to consult your vehicle’s manufacturer for specific guidelines and tolerances. Remember, accurate calibration ensures that your engine management system receives reliable data, facilitating efficient fuel injection and enhancing overall performance, much like well-tuned suspension components or high-performance air filters contribute to smoother handling and faster acceleration.

Tips for Maintaining Optimal Performance: Precautions and Best Practices

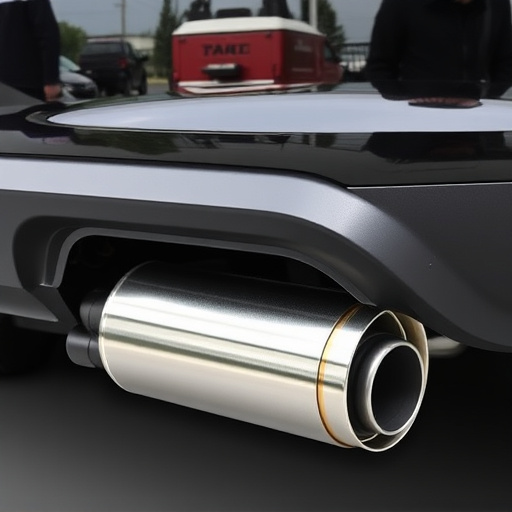

To maintain optimal performance in a tuned engine, regular Mass Air Flow (MAF) sensor calibration is paramount. Start by ensuring clean and intact intake components; any debris or damage can disrupt airflow readings. Next, check for proper wiring and connections to prevent inaccurate signals to the engine control unit (ECU). Regular replacement of the MAF sensor itself is also crucial as it ages, typically every 50,000 to 100,000 miles, depending on usage.

Beyond these basics, consider the interplay between your exhaust systems and the MAF sensor. Exhaust backpressure can influence airflow measurements, so keeping exhaust systems in good condition and minimizing restrictions is essential. Additionally, maintain a balanced air/fuel ratio through regular tuning and check for any leaks in the system, as they can compromise performance brakes. Always refer to manufacturer guidelines and consult with professionals when necessary to ensure your MAF sensor remains calibrated for peak efficiency.

Calibrating your vehicle’s Mass Air Flow (MAF) sensor is a key step in maintaining peak engine performance. By understanding how these sensors function within tuned engines and implementing the calibration process with precision, you ensure optimal fuel-air mixture delivery. Adhering to best practices and regular maintenance will safeguard your engine’s health, enhancing both efficiency and longevity. Remember, a well-calibrated MAF sensor is integral to the overall harmony of your tuned engine.