Exhaust system shops play a vital role in enhancing vehicle performance through turbo and header installations. By understanding these components' functions—turbochargers boosting engine power and headers optimizing exhaust flow—shops can offer specialized services, including custom designs and precision welding. Adhering to best practices, such as proper fitment, clean spaces, safety protocols, and regular tool inspection, ensures high-quality results with cat back exhaust systems and suspension components, ultimately satisfying customers.

In the realm of automotive performance upgrades, turbo and header installations have emerged as game-changers. Exhaust system shops play a pivotal role in these complex processes, ensuring optimal engine efficiency and exhaust flow. This article delves into the intricacies of turbo and header installs, highlighting the expertise required by exhaust system shops to successfully navigate this landscape. We’ll explore best practices and tips for achieving seamless integrations, enhancing both performance and reliability.

- Understanding Turbo and Header Installs: A Comprehensive Overview

- The Role of Exhaust System Shops in Turbo and Header Installations

- Best Practices and Tips for Successful Turbo and Header Installs at Exhaust System Shops

Understanding Turbo and Header Installs: A Comprehensive Overview

Understanding Turbo and Header Installs is crucial for any exhaust system shop aiming to provide top-tier services. These components are integral parts of a vehicle’s performance, especially in modified or high-performance cars. A turbocharger, often simply called ‘turbo’, is a forced induction device that increases an internal combustion engine’s power output by compressing more air than the atmospheric pressure allows. This process delivers a larger volume of oxygen to the engine, leading to increased fuel burning and more powerful performance.

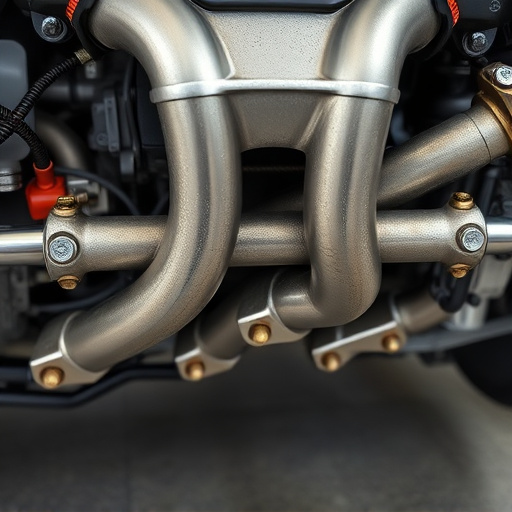

Header installs, on the other hand, are about optimizing exhaust flow from the cylinder head. Headers collect gases from multiple cylinders and direct them into the exhaust system, reducing backpressure in the combustion chamber. By improving gas flow, headers can enhance engine performance and efficiency. For exhaust system shops, proficiently handling turbo installs and header modifications ensures customer satisfaction and maintains the shop’s reputation as a reliable source for automotive enhancements, alongside services like suspension kits.

The Role of Exhaust System Shops in Turbo and Header Installations

Exhaust system shops play a pivotal role in facilitating turbo and header installations for vehicles. These specialized workshops are equipped with the necessary tools, knowledge, and expertise to handle complex modifications that enhance engine performance. They offer a range of services, from custom exhaust system designs to precision welding and fitting of high-performance components.

When it comes to turbo and header installations, exhaust system shops ensure proper fitment and alignment, optimizing gas flow for maximum efficiency. They also take into account the integration of suspension components and overall vehicle dynamics to maintain stability and handling. By combining their technical proficiency with the latest technologies, these shops deliver top-tier results, transforming a vehicle’s performance capabilities while ensuring safety and reliability through high-quality cat back exhaust systems.

Best Practices and Tips for Successful Turbo and Header Installs at Exhaust System Shops

When it comes to installing turbos and headers at an exhaust system shop, adhering to best practices is paramount for successful outcomes. One key tip is ensuring proper fitment, as even a slight misalignment can negatively impact performance. Exhaust system shops should employ high-quality tools and equipment, using them correctly to prevent damage to both the vehicle and the components themselves.

Additionally, maintaining clean working spaces and adhering to safety protocols are essential. This includes wearing appropriate personal protective equipment (PPE) and regularly inspecting tools for wear or damage. Regular training sessions on new technologies and techniques can also help keep technicians up-to-date with industry standards. For optimal results, exhaust system shops should consider offering services that encompass the entire process, from initial assessments to final tuning, ensuring a seamless experience for their clients and promoting customer satisfaction in regard to suspension components, cat back exhaust, and overall exhaust systems.

Exhaust system shops play a pivotal role in facilitating successful turbo and header installations, ensuring optimal engine performance. By adhering to best practices and employing skilled technicians, these shops offer specialized services that enhance vehicle efficiency and reliability. When considering turbo and header upgrades, it’s imperative to partner with reputable exhaust system shops for expert guidance and high-quality workmanship.