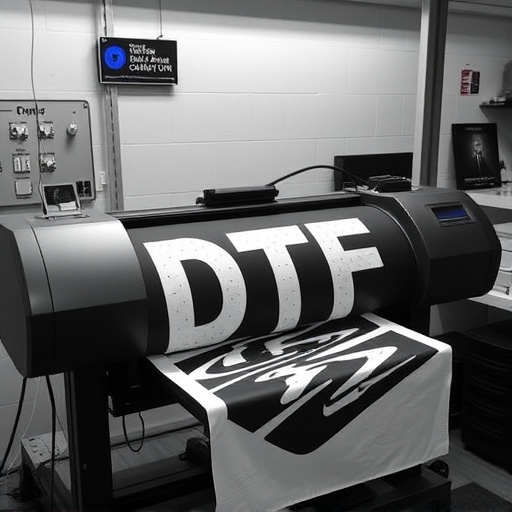

DTF Adhesive Powder is a revolutionary industrial solution offering superior bonding strength and durability for diverse applications. Utilizing Direct to Fabric (DTF) technology, it enables cost-effective logo transfers and intricate design work on textiles and plastics via ready-to-press transfers, streamlining manufacturing processes. Its strong adhesive properties ensure durable bonds in high-pressure environments, enhancing productivity and reducing downtime. Ideal for precise DTF transfers by size, this industrial-grade powder delivers exceptional results in manufacturing, automotive, and beyond, revolutionizing production with its fine texture and superior bonding strength while requiring careful application of heat press settings to prevent damage to delicate materials.

“Discover the transformative power of DTF Adhesive Powder, a game-changing bonding solution in industrial applications. This powerful compound offers exceptional strength and versatility, making it an indispensable tool for various sectors. From manufacturing to construction, its industrial-grade performance enhances productivity and efficiency. Explore the benefits and unique properties that set DTF powder apart. Uncover how this innovative adhesive is revolutionizing industries and fostering advanced manufacturing techniques.”

- Understanding DTF Adhesive Powder: A Powerful Bonding Solution

- Industrial Applications: Unleashing the Potential of DTF Powder

- Advantages and Considerations for Optimal Performance

Understanding DTF Adhesive Powder: A Powerful Bonding Solution

DTF Adhesive Powder stands as a powerful bonding solution, transforming various industrial applications with its exceptional performance. This innovative product is designed to create strong, durable bonds, making it a game-changer for many manufacturing and design processes. By utilizing DTF (Direct to Fabric) technology, the powder offers a cost-effective method for achieving high-quality logo transfers and intricate designs onto a variety of materials, from textiles to plastics.

Unlike traditional methods that can be time-consuming and costly, DTF transfers ready to press, ensuring a swift and efficient production process. The adhesive powder’s versatility allows for precise control during application, enabling detailed and accurate results. Its industrial-grade performance means enhanced durability, making products more resilient and suitable for demanding environments. Whether enhancing textiles or crafting intricate patterns, DTF Adhesive Powder is a reliable choice that promises to revolutionize the way we approach material bonding.

Industrial Applications: Unleashing the Potential of DTF Powder

The versatility of DTF Adhesive Powder is truly showcased when it comes to industrial applications. This powerful material has revolutionized various sectors, offering precise and efficient solutions. From manufacturing to automotive, its use extends across a wide range of industries. In the realm of precision engineering, DTF powder enables intricate dtf transfer by size, allowing for detailed designs and precise component assembly. Its strong adhesive properties ensure durable bonds, making it ideal for high-pressure environments.

Moreover, the industrial-grade performance of DTF Adhesive Powder translates into enhanced productivity and reduced downtime. It facilitates faster production cycles without compromising on quality, a significant advantage in today’s fast-paced manufacturing world. Whether used in creating intricate dtf transfer film designs or for structural bonding, this powder consistently delivers exceptional results, making it an indispensable tool in many industrial settings.

Advantages and Considerations for Optimal Performance

The DTF Adhesive Powder offers a range of advantages that make it a preferred choice for industrial applications. One key benefit is its superior bonding strength, ensuring long-lasting and robust connections between materials. This feature is particularly valuable in demanding industries where durability and reliability are paramount. Additionally, the powder’s fine texture enhances its adhesive properties, allowing for precise and detailed dtf transfers ready to press, catering to intricate design requirements.

To achieve optimal performance with DTF Adhesive Powder, consider specific settings and techniques. The recommended dtf heat press settings, when combined with proper application methods, can result in exceptional results. Precisely controlling temperature and pressure during the pressing process is crucial, ensuring the adhesive powder activates effectively without causing damage to delicate materials. By adhering to these considerations, users can take full advantage of the DTF Adhesive Powder’s capabilities, revolutionizing their production processes.

DTF Adhesive Powder stands out as a game-changer in industrial bonding solutions, offering unparalleled performance across various applications. By leveraging its unique properties, professionals can achieve superior results in tasks ranging from manufacturing to construction. Understanding the powder’s advantages and optimal use cases ensures maximum efficiency and durability, making DTF an essential consideration for any project requiring high-quality adhesive binding.