The engine intake system, comprising sensors like MAF, and modifications like cold air intakes, optimizes air and fuel delivery for enhanced performance and efficiency. Calibration is vital, ensuring precision through cleaning, proper connections, and software parameter adjustments to avoid sensor drift and maintain optimal fuel-air ratios. Regular maintenance prevents issues, leading to a smoother driving experience.

Unleash peak performance from your engine with a precise calibration of its intake system sensors. This guide delves into the intricate world of engine intake system sensors, offering a comprehensive understanding of their roles in optimizing combustion. We provide a detailed, step-by-step calibration process tailored for DIY enthusiasts and mechanics alike. Additionally, learn to identify and resolve common issues, ensuring your engine intake system operates at its most efficient. Master these techniques, and witness the tangible benefits in power, fuel efficiency, and overall vehicle dynamics.

- Understanding Engine Intake System Sensors

- Calibration Process: Step-by-Step Guide

- Common Issues and Troubleshooting Tips

Understanding Engine Intake System Sensors

The engine intake system is a complex network of components designed to draw in air and fuel, optimizing the engine’s performance. At the heart of this system are various sensors that play crucial roles in monitoring and controlling the flow of air and ensuring efficient combustion. One common sensor found in modern engines is the mass airflow (MAF) sensor, which measures the amount of air entering the engine. This data helps the vehicle’s computer adjust fuel injection accordingly, thereby improving overall performance.

Additionally, high-performance parts like cold air intakes and performance air filters can significantly impact intake system efficiency. These modifications enhance air flow by providing a direct route for cool, dense air to enter the engine. By ensuring optimal air-fuel mixture delivery, these upgrades contribute to increased power output and fuel economy. Understanding the interplay between these sensors and high-performance components is essential for achieving peak engine performance and maintaining ideal fuel efficiency.

Calibration Process: Step-by-Step Guide

Calibration is a meticulous process that ensures the precision and efficiency of your engine intake system components. Here’s a step-by-step guide to help you navigate this procedure:

1. Prepare Your Workspace: Begin by ensuring your workspace is clean, well-lit, and equipped with necessary tools such as specialized sensors, calibration kits, and a laptop for data logging. Connect the calibration equipment to your engine intake system according to the manufacturer’s instructions. This may include attaching pressure sensors or flow meters to key points within the air intake systems.

2. Initial Setup: Before initiating the calibration process, make sure all components are properly secured and sealed to avoid any potential interference. Start the engine and allow it to reach its operating temperature. Then, use your calibration software to set the desired parameters based on the specific sensors being used. This could involve inputting known air or fuel flow rates for accurate measurement. Once set, initiate the calibration routine, allowing the system to perform a series of tests that will fine-tune its accuracy.

Common Issues and Troubleshooting Tips

When it comes to calibrating sensors in an engine intake system, several common issues can arise. One of the most frequent problems is sensor drift, where readings become inaccurate over time due to wear and tear or exposure to extreme conditions. This can lead to incorrect fuel-air ratios, compromising engine performance and efficiency. Another issue is contamination, such as oil or debris, which can foul sensors and cause erratic readings. Improper installation is also a common pitfall; sensors must be meticulously aligned and secured for accurate signals.

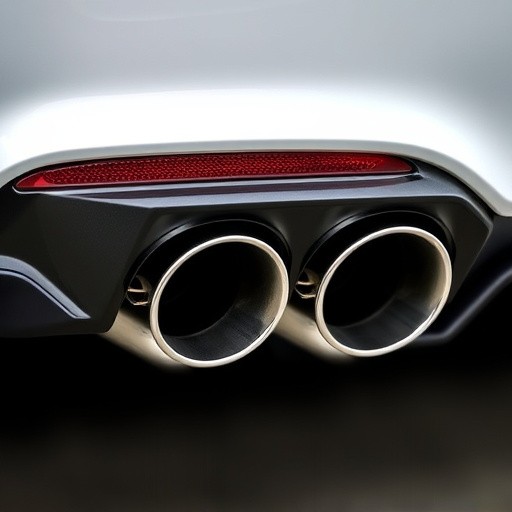

Troubleshooting these issues requires a systematic approach. Start by checking for any visible contaminants on the sensors and cleaning them thoroughly. Ensure all connections are tight and corrosion-free. If sensor readings remain inconsistent, consider using diagnostic tools to identify any unique codes or patterns indicating specific problems. Regular maintenance, including replacing worn parts like suspension kits or exhaust tips, and keeping brake components in check, can prevent many of these issues from occurring in the first place.

Calibrating sensors in your engine intake system is a crucial step in ensuring optimal performance. By following the step-by-step guide provided, you can effectively adjust and fine-tune these sensors for accurate readings. Being aware of common issues and troubleshooting tips will further assist in maintaining a well-calibrated intake system, ultimately enhancing fuel efficiency and engine power. Remember, a well-tuned engine intake system is key to maximizing the potential of your vehicle’s performance.