Commercial DTF Printing (Direct-to-Fabric Transfer Printing) is a revolutionary method for businesses to print designs onto fabric efficiently and cost-effectively. Using specialized equipment, including a DTF printer, high-quality films, and inks, this technology bypasses traditional screen printing by applying designs directly to fabric. The process involves preparing digital designs, applying the transfer film, curing ink, and removing the film for long-lasting, vibrant prints. With its versatility, wide color range, intricate detail capabilities, lower setup costs, and faster production times, Commercial DTF Printing has become a go-to method for bringing fabric designs to life.

Commercial DTF (Direct to Fabric) printing is a game-changing tech revolutionizing the textile industry. This beginner’s guide aims to demystify this process, offering a comprehensive overview for those new to its vast potential. From understanding the fundamentals of DTF printing to navigating equipment setup and design optimization, we’ll explore each step required to create vibrant, custom fabric products. Get ready to dive into this exciting world of commercial DTF printing.

- Understanding Commercial DTF Printing: The Basics

- Getting Started: Equipment and Materials Needed

- Mastering the Process: From Design to Final Product

Understanding Commercial DTF Printing: The Basics

Commercial DTF Printing, or Direct-to-Fabric Transfer Printing, is a cutting-edge technology that has revolutionized the textile industry. It involves the application of designs directly onto fabric using a special transfer film, offering an efficient and cost-effective solution for bulk printing. This process eliminates the need for intricate screen printing methods, making it an accessible option for businesses and entrepreneurs looking to print custom designs on various fabrics.

At its core, DTF printing comprises several steps: preparing the design digitally, applying the dtf transfer film to the fabric, curing the ink, and then removing the film to reveal the vibrant, long-lasting print. This innovative technique is not only versatile but also allows for a wide range of colors and intricate details, ensuring that final products are of exceptional quality. With its many advantages, including reduced setup costs and faster production times, Commercial DTF Printing has become a preferred method for those seeking to bring their fabric designs to life efficiently.

Getting Started: Equipment and Materials Needed

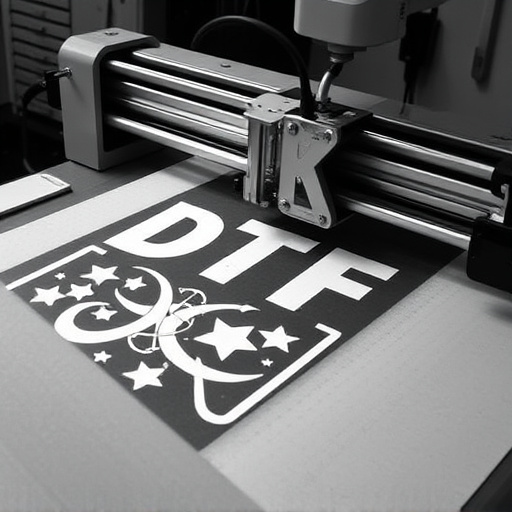

Getting Started with Commercial DTF Printing requires an investment in specific equipment and materials tailored for this advanced printing technique. Central to your setup is a Direct-to-Film (DTF) printer, designed to precisely deposit inks onto a film, which will then be used for subsequent transfer to various substrates. Alongside the printer, you’ll need high-quality DTF printing films compatible with your model, along with ink sets optimized for DTF application instructions.

Essential materials also include applicator tools for even film placement and a suitable workspace equipped with proper ventilation due to the volatile nature of inks. Understanding the required dtf design requirements is paramount; designs should be vector-based, with clean lines and minimal detail to ensure optimal printing quality. Once printed, the film undergoes a crucial dtf curing process to set the ink, ensuring long-lasting durability on transfer to materials like textiles or wood.

Mastering the Process: From Design to Final Product

Mastering the Process: From Design to Final Product

Commercial DTF (Direct-to-Fabric) printing is a straightforward yet sophisticated process that demands attention to detail at every stage. It begins with the design phase, where creators translate their artistic vision into digital formats suitable for printing. This involves using specialized software and ensuring the design meets the required specifications for DTF printing, including file size, resolution, and color profiles. Once the design is finalized, it’s time to prepare the fabric. The chosen material, whether it’s cotton, polyester, or a blend, needs to be clean, dry, and free from any impurities that could affect ink adhesion.

The next crucial step is setting up the DTF printer. These machines use heat to transfer the design onto the fabric, so maintaining proper temperature control and ensuring the printing surface is clean are essential. After loading the fabric into the printer, the process begins. The design is precisely applied using high-quality inks, creating vibrant, long-lasting colors. The final product is then carefully inspected for any imperfections, ensuring it meets the client’s expectations. For custom DTF gang sheets or orders, this process becomes even more intricate, requiring precise color matching and careful handling of bulk production runs to maintain consistency and quality across all pieces.

Commercial DTF (Direct-to-Fabric) printing is a game-changing technology for those looking to enter the textile industry. By understanding the basics, investing in the right equipment and materials, and mastering the design-to-product process, beginners can create high-quality, custom fabric prints. This guide has equipped you with the fundamentals to start your journey in commercial DTF printing, allowing you to explore endless creative possibilities in this vibrant and bustling field.