Fast DTF Transfers, a game-changer for printing businesses, offers efficient, cost-effective custom order solutions, especially for short runs or on-demand projects. To harness its potential, understanding key equipment like specialized printers, inks, and adhesives is crucial. Accessible online ordering systems empower businesses of all sizes to leverage Fast DTF's advantages, including rapid turnaround times. Optimal outcomes require strategic equipment selection, regular maintenance, and calibration to ensure precise cutting, bonding, and consistent results on media types like fabric, paper, or plastic.

In today’s fast-paced manufacturing landscape, efficient and precise Fast DTF (Direct To Final) transfers are crucial. This article delves into the essential equipment needed to streamline the process, ensuring accuracy and speed in production. We explore the understanding of Fast DTF transfers, highlight critical tools for a seamless experience, and provide tips for maintaining and calibrating your equipment to optimize performance. Essential for any modern workshop, this guide is your go-to resource for mastering Fast DTF Transfers.

- Understanding Fast DTF Transfers and Their Requirements

- Essential Equipment for Seamless DTF Transfer Process

- Tips for Maintaining and Calibrating Your Equipment

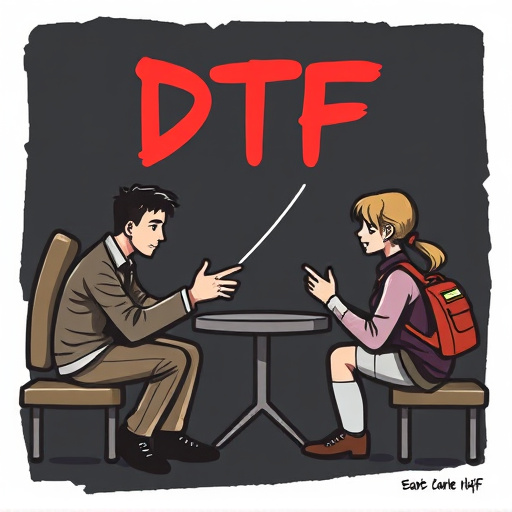

Understanding Fast DTF Transfers and Their Requirements

Fast DTF Transfers represent a cutting-edge technology for printing and producing high-quality images on various materials in record time. This process has revolutionized the way businesses handle custom orders, offering a cost-effective solution for short runs or unique, on-demand projects. Unlike traditional methods, Fast DTF allows for precise control over design and material interaction, ensuring exceptional results.

Understanding what equipment is essential for these transfers is key to achieving consistent quality. From specialized printers capable of handling diverse materials to the right inks and adhesives, each component plays a vital role in the success of DTF custom orders. Efficient online ordering systems also contribute to making this technology more accessible, allowing businesses of all sizes to take advantage of its benefits, including rapid turnaround times and, as a result, improved customer satisfaction.

Essential Equipment for Seamless DTF Transfer Process

For a smooth and efficient Fast DTF Transfers process, having the right equipment is paramount. The key tools ensure precise alignment, optimal pressure distribution, and even heat application, resulting in high-quality, detailed transfers. A top-tier DTF gang sheet builder stands as the foundation, enabling precise cutting and weeding for clean, crisp designs.

Complementing this is a reliable DTF heat press, meticulously adjusted with accurate heat press settings to match the material and design. This ensures the adhesive bonds securely without causing damage to the substrate or the design itself. Pair these with a quality DTF transfer film that aligns perfectly with your chosen medium, whether fabric, paper, or plastic, for seamless results every time.

Tips for Maintaining and Calibrating Your Equipment

To ensure optimal performance and accuracy in Fast DTF Transfers, proper equipment maintenance and calibration are paramount. Regular cleaning of your transfer machine is crucial to remove build-up and debris that can hinder its functionality. Use recommended cleaning solutions and follow the manufacturer’s guidelines to prevent damage. Additionally, calibrating your machine periodically guarantees precise temperature and pressure settings, ensuring consistent and high-quality dtf artwork transfers onto various materials.

Inspecting your supplies regularly is another vital step. Check for any signs of wear or damage in your dtf printed shirts, transfer paper, and ink. Replace worn-out components promptly to maintain the integrity of your Fast DTF Transfers. Proper storage conditions, including a clean and dry environment, further extend the lifespan of your equipment, contributing to enhanced dtf durability over time.

Fast DTF transfers require a specific set of equipment to ensure precision and efficiency. By understanding the process and investing in the right tools, from printers to software, you can achieve high-quality results. Regular maintenance and calibration are key to keeping your equipment in top condition, ensuring consistent and reliable fast DTF transfers every time.