DTF curing ovens are advanced manufacturing tools pivotal for modern industries, offering precise temperature control and efficient heat distribution. Their innovative design benefits include enhanced productivity, reduced energy consumption, and sustainable practices across various sectors. In print and garment manufacturing, these ovens revolutionize processes by ensuring uniform heating, minimizing defects, and delivering superior quality, making them ideal for fast, cost-effective custom printing on apparel and signage.

“The DTF Curing Oven is revolutionizing the heat transfer industry, offering a game-changer in smooth and efficient heating processes. This article delves into the intricacies of these innovative ovens, highlighting their crucial role in enhancing heat distribution. By understanding how DTF ovens ensure consistent warmth across surfaces, businesses can achieve high-quality results with reduced waste. From bustling workshops to advanced manufacturing facilities, this technology promises a reliable solution for precise heat transfers.”

- Understanding DTF Curing Ovens: Their Role in Heat Transfer

- How DTF Curing Ovens Ensure Smooth and Efficient Heat Distribution

- Benefits of DTF Curing Oven for High-Quality Heat Transfers

Understanding DTF Curing Ovens: Their Role in Heat Transfer

Understanding DTF Curing Ovens: Their Role in Heat Transfer

DTF curing ovens play a pivotal role in modern manufacturing processes, especially for heat transfer applications. These advanced ovens utilize a dynamic temperature control system, enabling precise and uniform heating of materials. This technology is particularly crucial for industries that deal with delicate or complex designs, ensuring consistent results without damaging the product. By offering cost-effective solutions, DTF curing ovens have become an indispensable tool in various sectors, catering to both small-scale and large-scale production needs.

The unique design of a DTF gang sheet builder within these ovens facilitates efficient heat distribution, enhancing overall productivity. With vibrant designs tailored to specific requirements, these ovens ensure optimal performance while reducing energy consumption. This not only makes them an environmentally friendly choice but also a smart investment for businesses seeking to streamline their operations and achieve high-quality outcomes.

How DTF Curing Ovens Ensure Smooth and Efficient Heat Distribution

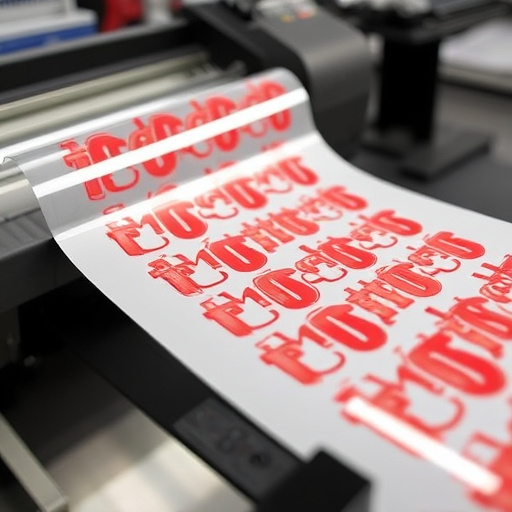

DTF (Direct to Film) Curing Ovens play a pivotal role in ensuring smooth and efficient heat distribution during the transfer printing process. Unlike traditional methods, these ovens utilize advanced technology to achieve consistent heating across the entire print area. This uniform heat application is crucial for creating high-quality DTF transfers, as it minimizes warping, bubbling, or uneven coloring often associated with inferior curing techniques.

The efficiency of a DTF Curing Oven lies in its ability to quickly and evenly set the inks, allowing for faster production times without compromising on quality. This feature not only streamlines the manufacturing process but also contributes to cost-effectiveness, making it an ideal choice for businesses specializing in custom apparel, signage, or other applications that demand high-quality DTF transfer printing.

Benefits of DTF Curing Oven for High-Quality Heat Transfers

The DTF (Direct to Fabric) Curing Oven is a game-changer when it comes to achieving smooth and high-quality heat transfers on various materials, especially in garment printing. Its primary benefit lies in the precision it offers during the curing process, ensuring that intricate dtf artwork transfers are accurately reproduced on fabrics. This level of control is particularly advantageous for businesses involved in dtf garment printing, enabling them to maintain consistent quality across every print job.

By utilizing a DTF Curing Oven, printers can streamline their production process and reduce waste. The oven’s ability to cure inks efficiently minimizes the risk of smudging or blurring, which is common with traditional methods. This advancement in technology has opened up opportunities for online ordering platforms specializing in dtf artwork transfers, as customers now expect flawless results when customizing their garments.

The DTF curing oven stands as a game-changer in heat transfer technology, offering both efficiency and precision. By understanding its role in ensuring smooth and uniform heat distribution, it’s clear that this innovation is key to achieving high-quality results in various industries. Investing in a DTF curing oven can significantly enhance production processes, making it an essential tool for anyone seeking optimal heat transfers.