DTF Powder Adhesive is a game-changer in graphic design and printing, offering precise transfers, customizable properties via uploadable gang sheets, and durable, vibrant designs. Before use, professionals should prioritize safety and workspace preparation. Evenly spreading the adhesive on a design transfer or apparel with precision tools enhances print quality. This method allows for intricate custom DTF transfers suitable for apparel or craft projects.

“Unleash the power of DTF Powder Adhesive—a game-changer in the realm of professional bonding. This versatile adhesive offers unparalleled strength and versatility, making it a favorite among industry pros. Our guide delves into the intricate world of DTF application, providing valuable insights for achieving optimal results. From understanding its unique properties to mastering safety protocols, you’ll discover expert tips to enhance your workflow. Elevate your projects with this revolutionary adhesive.”

- Understanding DTF Powder Adhesive: Properties and Benefits

- Preparation and Safety Measures for Professional Application

- Step-by-Step Guide to Achieving Optimal Results with DTF Powder Adhesive

Understanding DTF Powder Adhesive: Properties and Benefits

DTF Powder Adhesive is a revolutionary material that has transformed various industries, particularly in the realm of graphic design and printing. Understanding its unique properties is crucial for professionals aiming to master its application. This adhesive is renowned for its ability to facilitate precise and efficient transfers, making it a game-changer in many creative processes. Its key advantage lies in the precision it offers; DTF (Direct to Form) transfer by size ensures that designs are accurately replicated onto various surfaces, from clothing to accessories.

The benefits of using DTF Powder Adhesive extend beyond its accuracy. It is known for its versatility, allowing users to upload their own gang sheets and customize the adhesive properties to suit specific projects. This level of customization enables professionals to handle bulk orders with ease, as they can tailor the adhesive to meet the unique requirements of each client or design. Moreover, the adhesive’s durability ensures that transferred designs remain indelible and vibrant, enhancing the overall quality of the final product.

Preparation and Safety Measures for Professional Application

Before tackling any DTF Powder Adhesive application, professionals should meticulously prepare and prioritize safety measures for a successful outcome. This involves gathering all necessary tools and materials, including protective gear such as gloves, masks, and safety goggles to prevent skin and eye contact with the adhesive powder. A well-ventilated workspace is crucial, especially in enclosed areas, to avoid inhaling toxic fumes.

Additionally, ensure proper lighting to facilitate accurate application and inspection of the work area. For optimal results, professionals should adhere to manufacturer guidelines regarding surface preparation, priming, and drying times. Custom DTF gang sheets can be utilized for large-scale projects, enhancing efficiency and ensuring durable prints. Even for smaller orders, these measures are essential to maintain quality and consistency in every application.

Step-by-Step Guide to Achieving Optimal Results with DTF Powder Adhesive

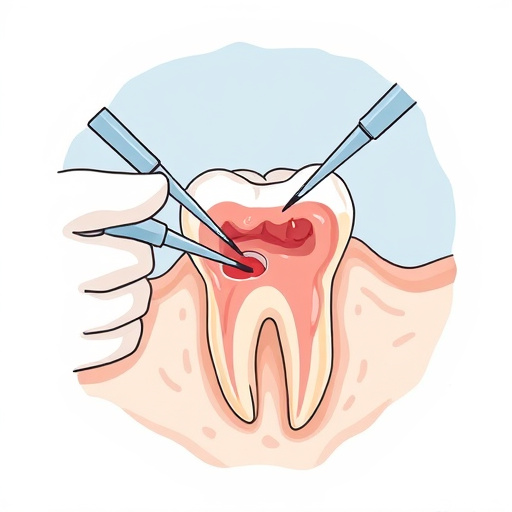

To achieve optimal results with DTF Powder Adhesive, follow this step-by-step guide. Begin by preparing your workspace and gathering all necessary materials, including the DTF powder adhesive, applicators, and a clean surface for application. Ensure excellent ventilation to minimize exposure to dust particles. Next, carefully measure the required amount of DTF powder adhesive according to the project’s scale and spread it evenly on one side of your design transfer or custom dtf apparel using a precision tool or brush.

For precise application, place your design transfer onto the target material, ensuring complete coverage without gaps or overlaps. Use a smooth, even pressure to secure the transfer in place. Allow the adhesive to set for a short period as per the manufacturer’s instructions. Once cured, carefully remove the backing film to reveal the adhered dtf design. This method is ideal for creating intricate custom dtf transfers that add vibrant designs to various substrates, enhancing their aesthetic appeal and functionality in dtf custom apparel or other craft projects.

The application of DTF Powder Adhesive offers professionals a versatile and efficient bonding solution. By understanding its unique properties, implementing proper preparation and safety protocols, and following a systematic approach, experts can achieve superior results in various industrial applications. This adhesive’s versatility makes it a valuable tool for those seeking durable bonds across different materials, ensuring a seamless and professional finish.