DTF Printing Equipment is a versatile solution for diverse printing needs, offering direct ink application onto textiles like cotton, polyester, and blends. The process involves fabric preparation, precise ink deposit, and heat/UV curing for exceptional design flexibility. Adaptable to small-scale and large-volume productions, it enhances productivity and ensures high-quality prints. DTF is favored in fashion, apparel, sportswear, and home decor for its material compatibility, production efficiency, superior print quality, and cost reduction compared to conventional methods.

“Unleash creative possibilities with DTF (Direct-To-Fabric) printing equipment—a game-changer for businesses seeking versatile textile printing solutions. This cutting-edge technology empowers printers to produce stunning designs on a variety of fabrics, including cotton, polyester, and blends.

In this article, we’ll explore the ins and outs of DTF printing equipment, its material compatibility, and the diverse industry applications that benefit from its efficient and high-quality output.”

- Understanding DTF Printing Equipment and Its Versatility

- Material Compatibility: Cotton, Polyester, and Blends

- Benefits of Investing in DTF Printing for Various Industries

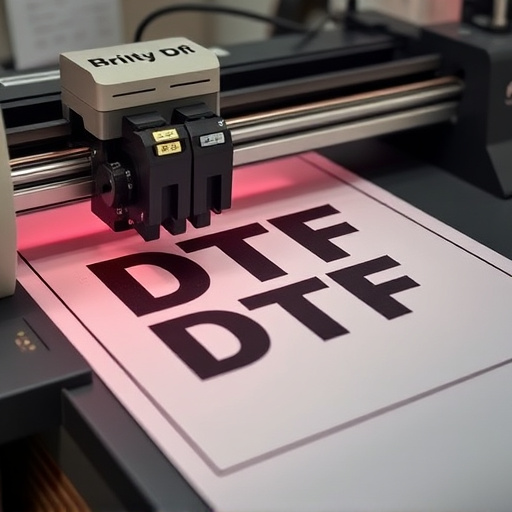

Understanding DTF Printing Equipment and Its Versatility

DTF Printing Equipment has emerged as a versatile and efficient solution for various printing needs. This technology allows for the direct application of ink onto textiles, making it suitable for printing on cotton, polyester, and blends. The process involves a series of steps where fabric is first prepared, then ink is precisely deposited, and finally, the ink is cured using heat or UV light. This method offers unparalleled design flexibility and precision.

The versatility of DTF Printing Equipment lies in its ability to handle different fabric types and compositions. Whether it’s the soft texture of cotton, the durability of polyester, or blends for a range of applications, this equipment ensures high-quality results. Custom DTF gang sheets further enhance productivity by allowing for efficient printing on multiple garments at once, making it an attractive option for both small-scale and large-volume production runs.

Material Compatibility: Cotton, Polyester, and Blends

DTF (Direct-to-Fabric) Printing Equipment is renowned for its versatility when it comes to material compatibility. This technology allows printers to create high-quality dtf transfers for a wide range of fabrics, including cotton, polyester, and blends. The ability to print on these diverse materials opens up a world of possibilities for designers and businesses looking to produce vibrant designs with intricate details.

Cotton remains a popular choice due to its natural softness and breathability. Polyester, known for its durability and wrinkle-resistant properties, is another favorite among fabric manufacturers. Blends combining cotton and polyester offer the best of both worlds—a comfortable feel from cotton paired with enhanced strength and longevity from polyester. With the right DTF gang sheet builder, these materials can be seamlessly integrated into printing processes, ensuring that final products deliver outstanding visual appeal and superior quality.

Benefits of Investing in DTF Printing for Various Industries

Investing in DTF (Direct to Fabric) Printing Equipment brings a multitude of benefits across various industries. From fashion and apparel to sportswear and home decor, DTF printing has revolutionized custom fabric design and production. Its versatility allows for printing on a wide range of materials, including cotton, polyester, and blends, enabling businesses to cater to diverse customer demands. This technology offers faster turnaround times, higher quality prints, and cost-effectiveness compared to traditional methods.

For apparel manufacturers, DTF garment printing streamlines the process, allowing for intricate designs and vibrant colors on t-shirts, hoodies, and more. In home decor, it facilitates the creation of unique fabric patterns for curtains, throw pillows, and upholstery. Moreover, DTF heat transfers enable the application of designs to a variety of products, from mugs and phone cases to bags and shoes, opening up new avenues for businesses to explore and expand their product lines. With its efficiency and versatility, DTF gang sheet builder systems are a valuable asset for any industry looking to enhance their custom printing capabilities.

DTF (Direct-to-Fabric) printing equipment offers a versatile solution for businesses seeking to print on various fabrics, including cotton, polyester, and blends. Its ability to handle multiple material types makes it an attractive investment for diverse industries, from apparel to home goods. By leveraging DTF Printing Equipment, businesses can create high-quality, custom designs with exceptional speed and efficiency, opening up new opportunities for innovation and growth in today’s competitive market.