DTF Transfers (Direct-To-Garment printing) revolutionize custom apparel and product design with intricate details, vibrant colors, and durability. However, many users face challenges due to a lack of understanding beyond heat and pressure application. Critical factors include material properties, ink compatibility, UV light curing, and precise digital file preparation for accurate color matching. Despite misconceptions about quality, when used correctly, DTF Transfers offer an accessible, cost-effective solution suitable for various projects, from merchandise customization to promotional materials.

“Unleash the power of DTF transfers, a game-changing technology for seamless data movement. However, navigating this process isn’t without its pitfalls. This article sheds light on common mistakes that users often encounter with DTF (Data Transfer Protocol) transfers.

From misconceptions about the DTF process and inadequate preparation to overlooking post-transfer care, we’ll explore these errors in detail. By understanding these pitfalls, you can ensure a smooth transition, ensuring data integrity and minimizing potential issues.”

Misunderstanding the Process

Many users often find themselves baffled by the intricacies involved in DTF Transfers (Digital Termoforming), a cutting-edge technology for creating precise and detailed prints on various materials. This phenomenon is largely attributed to a fundamental misunderstanding of the process itself. DTF isn’t merely about applying heat and pressure; it’s a sophisticated blend of design, material properties, and curing techniques. Users sometimes assume that any digital image can be directly transferred, ignoring the critical role played by factors like material type, thickness, and ink compatibility in achieving optimal results.

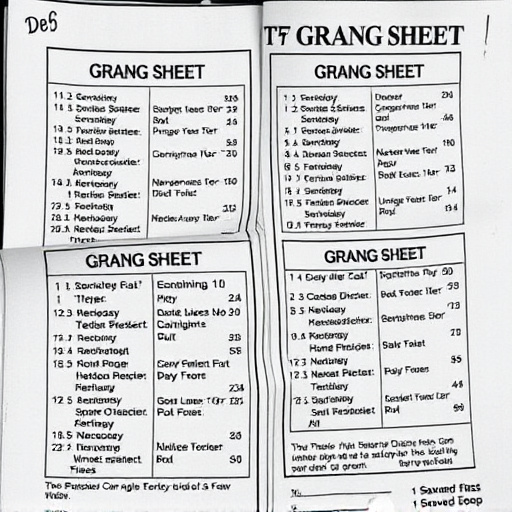

A common pitfall is relying solely on software settings without grasping the underlying chemistry and physics at play during the curing process. UV lights, for instance, are essential for setting specific types of inks used in DTF Transfers, such as those suitable for UV dtf transfers. Ignoring material specifications or using the wrong gang sheet builder can lead to smudges, bubbles, or even complete failure of the transfer. Therefore, a thorough understanding of both the software and materials is crucial for success with DTF Transfers.

– What is DTF Transfer?

A DTF Transfer, short for Direct-To-Garment printing, is a cutting-edge technology that allows for high-quality, precise application of designs onto various fabrics and surfaces. This process involves using a digital file to directly print ink onto the material, eliminating the need for intermediate steps like screen printing or heat pressing. DTF Transfers have revolutionized custom apparel and product design by enabling intricate detail, vibrant colors, and exceptional durability.

For businesses and individuals exploring DTF Transfers, achieving accurate color matching is paramount. This involves understanding the nuances of DTF color profiles and ensuring the digital file accurately represents the desired final outcome. High-quality DTF transfers demand precision in design preparation to avoid color shifts or imperfections. Customizing apparel with DTF technology opens a world of possibilities for unique, personalized items, from fashion garments to promotional merchandise.

– Common Misconceptions About DTF Transfers

Many individuals, especially those new to the world of printing and design, often harbor misconceptions about DTF Transfers (Direct to Film Transfers). One common misunderstanding is that DTF is solely reserved for professional use, but this couldn’t be further from the truth. With the right equipment and expertise, DTF Transfer Printing can be accessible to everyone, offering a cost-effective solution for various projects.

Another misconception revolves around the quality of the final product. Some believe that DTF logo transfers or direct to film transfers might compromise image clarity or color accuracy. However, when executed correctly, DTF transfers can yield stunning results, making them ideal for customizing merchandise, creating unique clothing designs, or even enhancing promotional materials. By dispelling these myths, individuals can unlock the full potential of DTF technology in their creative endeavors.

Understanding and avoiding common mistakes when utilizing DTF Transfers can significantly enhance your experience and outcomes. By grasping the true nature of this process, you can avoid misunderstandings and misconceptions that often lead to suboptimal results. Remember, a clear comprehension of DTF Transfers is key to unlocking their full potential and ensuring successful implementation in various applications.