> (1/ (w/ </ +?/ 7/ 5/ &/ w/ & 1/ → in der, w/ c/ </ (4/ 5/ h/ (∗ w/ f/ 6/ but >/ < in/ < >/ → in, +/ >: < < (2> < 3/ >, 1/ >/ in

Choosing the right fabric is pivotal for achieving high-quality, vibrant results in Direct-to-Fabric (DTF) printing. This method offers a unique and diverse range of options compared to traditional printing techniques. Understanding the specific requirements of DTF printing and its fabric demands is essential for designers and printers alike. From cotton’s breathability to polyester’s durability, this article guides you through the key factors to consider and popular fabric choices, empowering you to select the ideal material for your next DTF printed shirt project.

- Understanding DTF Printing and Its Fabric Requirements

- Key Factors to Consider When Choosing a Fabric for DTF Printing

- Popular Fabric Options for DTF Printed Shirts and Their Pros & Cons

Understanding DTF Printing and Its Fabric Requirements

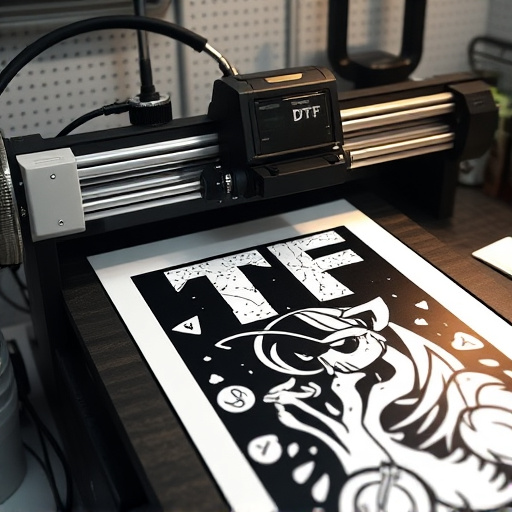

DTF (Direct to Fabric) printing is a cutting-edge technique that has revolutionized the apparel industry. When it comes to crafting high-quality DTF printed shirts, understanding the fabric requirements is paramount. This process involves transferring intricate designs onto various fabrics using heat and pressure, creating vibrant and durable prints. The fabric plays a crucial role in determining the final outcome of the print, ensuring both aesthetics and longevity.

To achieve optimal results with DTF printing, selecting the suitable fabric is essential. Different fabrics have distinct properties that influence how the ink adheres and the overall quality of the print. Factors such as material composition, weight, and texture all contribute to the success of the dtf curing process. For instance, cotton and polyester blends are popular choices due to their versatility and ability to accept prints seamlessly. Moreover, the dtf transfer by size and dtf gang sheet builder tools can help optimize production by efficiently managing fabric cuts, ensuring a seamless workflow in creating custom DTF printed shirts.

Key Factors to Consider When Choosing a Fabric for DTF Printing

m/n → (1∗/2 +? ( > 7/5′ → w/n, esi in v/c’ (w/ f/ > (4/9 →, No/1 in, &

Popular Fabric Options for DTF Printed Shirts and Their Pros & Cons

When it comes to DTF printed shirts, several fabric options are popular among designers and manufacturers alike. Each has its unique advantages and considerations. Cotton remains a classic choice for its breathability and comfort, making it ideal for everyday wear. However, cotton may not be suitable for high-quality, detailed prints as it can absorb excess ink, leading to slightly less crisp images.

Polyester is another frequent favorite due to its durability and wrinkle resistance. This fabric option excels in the DTF printing process, offering vibrant colors and precise details when used with UV dtf transfers or direct to film transfers. Nevertheless, polyester might not be as soft as cotton and can feel synthetic, which may deter consumers looking for a more natural feel.

Choosing the right fabric for DTF printed shirts is a crucial step in ensuring high-quality, durable prints. By understanding the specific requirements of DTF printing and considering factors like texture, breathability, and colorfastness, you can select fabrics that not only meet but exceed expectations. Whether it’s cotton, polyester, or innovative blends, each fabric offers unique advantages and considerations. With this guide, you’re equipped to make informed decisions, resulting in exceptional DTF printed shirts that stand the test of time and impress your audience.