Direct-to-Film (DTF) transfers are transforming custom printing with cutting-edge technology, enabling precise, vibrant prints on diverse substrates like fabrics, plastics, and metals. This game-changing method offers swift production times, exceptional image quality, and cost-effectiveness, making it popular among designers and businesses. To scale efficiently, optimize equipment placement, leverage advanced software for automation, and maintain intricate design precision to meet growing demand while upholding quality standards in the competitive custom DTF market.

Direct-to-Film (DTF) transfers are transforming custom printing, offering unparalleled versatility and quality. This article delves into the world of DTF technology, exploring its fundamental principles and the benefits it brings to businesses looking to scale their printing operations. From precise color reproduction to swift production times, DTF is revolutionizing customization. We’ll guide you through effective strategies for implementing and scaling DTF printing, enabling efficient production of unique, high-quality products.

- Understanding Direct-to-Film Transfers: The Basics

- Benefits of Using Direct-to-Film Transfers for Custom Printing

- Scaling Up: Strategies for Efficient DTF Printing Operations

Understanding Direct-to-Film Transfers: The Basics

Direct-to-Film (DTF) Transfers are a cutting-edge technology revolutionizing custom printing. Unlike traditional methods that involve multiple steps and intermediate materials, DTF transfers directly apply ink to the surface of a film, which is then pressed onto various substrates like t-shirts, mugs, or even metal. This innovative process offers unparalleled precision and vibrancy in prints, making it a favorite among designers and businesses looking for high-quality, durable designs.

The key to successful DTF transfers lies in understanding the custom dtf transfers design requirements. Designers need to optimize their artwork for specific substrate types and consider factors like ink compatibility and resolution. Achieving the right balance ensures that final products feature crisp details and vibrant colors, showcasing the full potential of durable prints. This method’s efficiency and versatility make it a game-changer in the printing industry, catering to diverse applications from promotional items to personalized merchandise.

Benefits of Using Direct-to-Film Transfers for Custom Printing

Direct-to-Film Transfers (DTF) for custom printing offer several compelling advantages that set them apart from traditional methods. One of the key benefits is their versatility; DTF allows for high-quality printing on a wide range of materials, including fabrics, plastics, and even metals. This makes it an ideal choice for creating personalized dtf custom apparel, dtf garment printing, or intricate dtf heat transfers. With direct application to the substrate, DTF ensures fast and efficient production times, enabling businesses to meet demanding deadlines with ease.

Additionally, this technology provides exceptional image quality and vibrant colors, delivering visually stunning results. The process is also cost-effective, especially for smaller runs or unique designs, as it minimizes waste and requires less setup time compared to traditional printing methods. DTF’s ability to produce detailed, long-lasting prints directly onto film makes it a game-changer in the realm of custom printing, catering to various industries and applications.

Scaling Up: Strategies for Efficient DTF Printing Operations

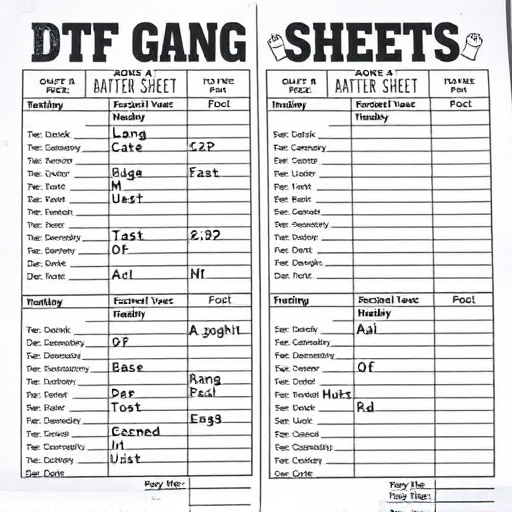

As your direct-to-film (DTF) printing business grows, scaling operations efficiently becomes paramount to meet increasing demand for custom dtf gang sheets and maintain high-quality standards. Implementing strategic practices is crucial for a seamless transition from small-batch production to larger-scale DTF custom apparel manufacturing. One key approach involves optimizing equipment and workspace layout, ensuring machinery is strategically positioned to minimize material handling and maximize throughput. This streamlined workflow enables faster turnaround times without compromising the meticulousness required for intricate dtf transfer film designs.

Additionally, leveraging advanced software solutions can significantly enhance productivity. Automation tools can streamline order processing, inventory management, and quality control checks, allowing operators to focus on complex design elements rather than administrative tasks. By integrating these strategic changes, your DTF printing operations will be well-equipped to handle higher volumes while retaining the precision and creativity that set custom DTF gang sheets apart in a competitive market.

Direct-to-film transfers (DTF) offer a revolutionary approach to custom printing, streamlining production and expanding creative possibilities. By understanding the basics and leveraging efficient scaling strategies, businesses can unlock the full potential of DTF technology. As demand grows, adopting best practices for DTF printing operations ensures faster turnaround times, higher quality outputs, and cost-effectiveness, making it an ideal solution for scaling custom printing services.