The DTF Curing Oven is a game-changer in DTG (Direct to Garment) printing, offering businesses an efficient and effective solution for high-quality custom apparel production. This advanced equipment combines precise temperature control and rapid drying times, significantly reducing manual curing time while achieving vibrant, long-lasting prints on various materials. Ideal for high-volume printing operations, it boosts production speed and overall efficiency, empowering professionals and businesses to streamline their printing workflows and gain a competitive edge.

The DTF Curing Oven is transforming industrial processes, offering a game-changing solution for rapid curing and drying. This advanced technology boosts speed and workflow efficiency, addressing key challenges in various sectors. By understanding its unique features and benefits, businesses can harness the power of DTF curing to streamline operations, reduce cycle times, and achieve superior outcomes. Explore real-world applications to uncover why this innovative oven is a must-have for modern manufacturing.

- Understanding the DTF Curing Oven and Its Unique Features

- How DTF Curing Ovens Boost Speed and Efficiency in Workflows

- Real-World Applications and Benefits of DTF Curing Technology

Understanding the DTF Curing Oven and Its Unique Features

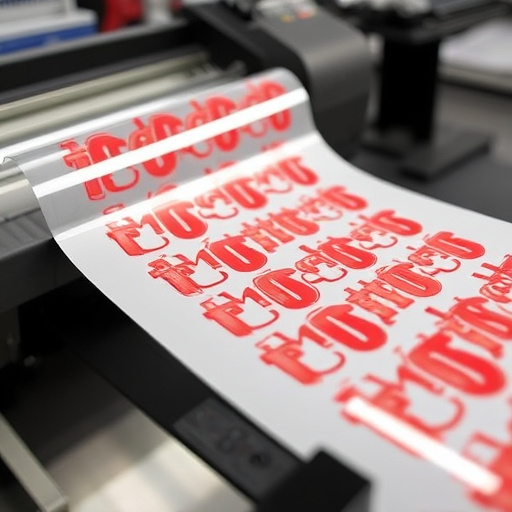

The DTF Curing Oven is a game-changer in the world of DTG (Direct to Garment) printing, revolutionizing the way businesses approach custom apparel. This advanced piece of equipment is designed to streamline the entire dtf curing process, from application to final product. What sets it apart is its unique ability to offer precise temperature control and rapid drying times, ensuring high-quality dtf transfers with consistent results.

By utilizing innovative technology, the oven provides an optimal environment for ink curing, allowing designers and printers to achieve vibrant, long-lasting prints on a variety of materials. Its efficient workflow design reduces the time typically required for manual curing, making it an ideal solution for high-volume printing operations. Whether you’re a professional in the industry or a business looking to enhance your DTG capabilities, understanding the intricacies of this oven and its potential can significantly boost your production speed and overall efficiency.

How DTF Curing Ovens Boost Speed and Efficiency in Workflows

The DTF (Direct to Fabric) Curing Oven is a game-changer in the print-on-demand and custom apparel industries. Its primary advantage lies in significantly speeding up the production process, which is crucial for businesses aiming to enhance workflow efficiency. With this technology, the curing step, often a time-consuming aspect of the dtf printing process, is optimized, eliminating the need for lengthy drying times. This innovation allows printers to produce high-quality, printed fabrics at an accelerated rate, meeting the growing demands of modern businesses.

Moreover, these ovens enable precise temperature control, ensuring consistent and excellent results every time. By offering a streamlined approach to the dtf custom apparel production, it empowers businesses to handle larger orders without compromising quality or speed. Users can simply upload their own gang sheet designs and let the oven do its magic, revolutionizing the way they manage their printing workflows.

Real-World Applications and Benefits of DTF Curing Technology

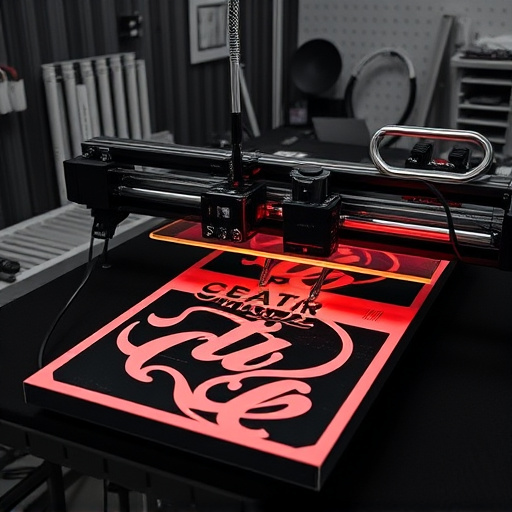

The DTF Curing Oven is a game-changer in various industries, offering a streamlined approach to material hardening and drying processes. Its real-world applications are vast, from manufacturing and automotive to graphics printing and even fashion design. This innovative technology accelerates production by significantly reducing cure times, allowing businesses to meet the ever-growing demand for rapid prototyping and small-batch production.

One of its key advantages is the ability to achieve precise color matching during the dtf curing process, ensuring consistent and vibrant results in applications like dtf logo transfers. This precision extends to various materials, enabling efficient processing of diverse substrates without compromising quality. By optimizing workflow efficiency, the DTF Curing Oven empowers businesses to enhance productivity, reduce labor costs, and deliver products faster, ultimately gaining a competitive edge in their respective markets.

The DTF Curing Oven represents a significant advancement in additive manufacturing, offering unparalleled speed and efficiency gains. By leveraging its unique capabilities, manufacturers can streamline workflows, reduce production times, and unlock new possibilities in rapid prototyping and low-volume production. As the adoption of DTF curing technology continues to grow, its impact on various industries will only become more profound, making it a game-changer for those seeking to enhance their manufacturing processes.