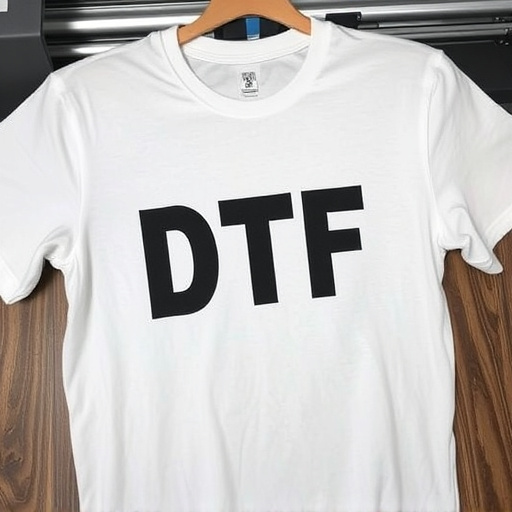

The DTF (Direct to Film) Heat Press is a cutting-edge technology that revolutionizes design transfer creation and application, offering unparalleled versatility with both hot and cold peel films. This innovative system enables businesses to efficiently produce high-quality dtf design transfers with minimal effort, perfect for small batch runs or on-demand printing. With fast delivery times, superior quality designs, and control over the transfer process, the DTF Heat Press is ideal for professionals seeking dynamic, personalized items. Key benefits include quick cutting times, safe removal of intricate designs, and simplified bulk order management, enhancing printing efficiency for custom apparel, signage, and more.

Discover the revolutionary power of the DTF Heat Press, a game-changer in the printing industry. This cutting-edge technology seamlessly integrates hot and cold peel films, offering unparalleled versatility. Unlock a world where vibrant, high-quality designs can be effortlessly transferred to various materials—from textiles to promotional products.

In this guide, we’ll explore the benefits of DTF (Direct-to-Fabric) heat press technology, its unique film applications, and practical tips for achieving flawless results.

- Understanding DTF Heat Press Technology

- Benefits of Using Hot and Cold Peel Films

- Applications and Best Practices for DTF Heat Press with Peel Films

Understanding DTF Heat Press Technology

The DTF (Direct to Film) Heat Press is a game-changing technology revolutionizing the way we create and apply design transfers. Unlike traditional methods, this innovative system allows for both hot and cold peel films, offering unparalleled versatility in the print industry. With a DTF Heat Press, businesses can efficiently produce high-quality dtf design transfers with minimal effort.

This technology enables fast delivery of customized products, making it an ideal choice for small batch runs or on-demand printing. The ability to use hot and cold peel films ensures that designers and printers have more control over the transfer process, resulting in superior quality and longer-lasting designs. Whether you’re a professional graphic designer or a business owner looking to offer unique, personalized items, understanding DTF Heat Press technology is a step towards staying ahead in the market with dynamic and high-quality dtf transfers.

Benefits of Using Hot and Cold Peel Films

Using hot and cold peel films with a DTF Heat Press offers numerous advantages for businesses and designers looking to enhance their printing process. One of the key benefits is speed and efficiency; these films enable quick, precise cutting, ensuring fast turnaround times for orders, which is especially advantageous for meeting tight deadlines or accommodating dtf fast delivery requests.

Additionally, cold peel films allow for easy removal of the printed design from the press plate, reducing the risk of damage to the delicate artwork. This feature is crucial when handling intricate designs or working with various materials. Furthermore, with the option to upload your own gang sheet, businesses can maintain control over their printing templates and easily manage bulk orders, streamlining production and catering to diverse customer needs.

Applications and Best Practices for DTF Heat Press with Peel Films

The DTF Heat Press is a versatile tool that opens up a world of creative possibilities for designers and printers. Its unique ability to work with both hot and cold peel films makes it suitable for a variety of applications, from creating custom t-shirts and accessories to designing eye-catching signage and decor. One of the key benefits of using DTF (Direct-to-Film) transfers ready to press is the precision and quality they offer.

When utilizing DTF Heat Press with peel films, best practices include ensuring your design software and DTF application instructions are perfectly aligned. It’s important to upload your own gang sheet, optimizing it for the specific film type and press settings. Proper preparation of the substrate, including cleaning and ensuring its surface is free from debris or oils, will yield better results. Additionally, paying attention to heat and pressure settings tailored to each material is crucial for achieving crisp, long-lasting prints without damaging the substrate or the film.

The DTF Heat Press, with its versatility in handling both hot and cold peel films, offers a wide array of creative possibilities. By understanding this technology and implementing best practices, businesses can harness the benefits of faster production times, enhanced print quality, and reduced waste, revolutionizing their custom product offerings. Whether for promotional items or personalized gifts, the DTF Heat Press is an indispensable tool in today’s competitive market, enabling businesses to deliver high-quality, unique products promptly.