DTF (Direct-To-Film) film sheets, made from advanced materials like polypropylene or polyester, are essential for creating detailed and vibrant textile prints on various fabrics. Quality control involves rigorous inspections of raw materials and file preparation to ensure precision cutting, color accuracy, and durability. Despite challenges like ink bleeding and misregistration, optimal results can be achieved through proper material selection, equipment maintenance, up-to-date software, and strict quality control checks, meeting industry standards for DTF film sheets in custom printing and heat transfers.

“Unleash the full potential of your DTF (Direct To Film) printing process with our comprehensive guide. This article delves into the intricacies of DTF film sheets, highlighting their materials and pivotal role in achieving top-tier prints. We demystify the quality control process, offering insights to ensure consistent performance. Additionally, discover common pitfalls and learn preventive strategies for flawless DTF film sheets. Maximize your printing accuracy and efficiency with these expert tips, tailored specifically for this innovative technology.”

- Understanding DTF Film Sheets: Materials and Their Importance

- Quality Control Process for Ensuring Optimal Performance

- Common Issues and How to Prevent Them in DTF Film Sheets

Understanding DTF Film Sheets: Materials and Their Importance

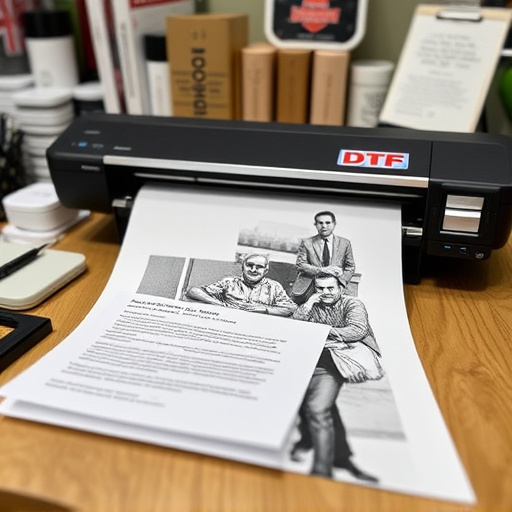

DTF (Direct-To-Film) film sheets are a crucial component in the world of textile printing and custom DTF heat transfers. These high-quality, precision-cut films serve as a medium to transfer intricate vibrant designs onto various fabrics. The materials used in DTF film sheets play a significant role in ensuring the longevity and quality of the final print.

Manufactured with advanced technologies, these sheets offer superior adhesion, color accuracy, and durability. The specific materials, including polypropylene or polyester, are chosen based on their compatibility with different printing methods and fabric types. Understanding the composition and properties of DTF film sheets is essential for printers to achieve exceptional results, ensuring that custom DTF transfers meet industry standards and customer expectations.

Quality Control Process for Ensuring Optimal Performance

The quality control process for DTF (Direct to Film) film sheets is a critical step in ensuring optimal performance and exceptional results during printing and transfer. It involves a series of meticulous checks at each stage, from raw material inspection to final product testing. By implementing rigorous quality standards, manufacturers can guarantee the integrity of the DTF film sheets, ensuring they meet the required specifications.

This process begins with examining the raw materials used for preparation, including the selection of high-quality base films and ink formulations. Proper file preparation is also paramount; designers should optimize their DTF files, considering aspects like resolution, color profiles, and bleed settings to prevent errors during printing. Additionally, random samples from each batch are selected and tested for precision cut accuracy, color consistency, and overall print quality, ensuring that the final products adhere to the highest standards.

Common Issues and How to Prevent Them in DTF Film Sheets

DTF film sheets, while offering numerous benefits for custom printing and transfers, are susceptible to several common issues that can compromise their quality. One of the primary concerns is ink bleeding, which occurs when ink seeps into adjacent areas, leading to smudges and distorted designs. This issue can be prevented by ensuring proper preparation of the film sheet, including using high-quality materials and adhering to recommended printing guidelines. Another frequent problem is misregistration, resulting in misaligned prints, especially during complex multi-color jobs. Careful calibration of your printing equipment and utilizing registration marks on the film sheets can significantly reduce this issue.

To maintain top-notch DTF transfers ready to press, fast delivery times, and customized designs, it’s crucial to address these potential problems proactively. Regular cleaning and maintenance of your printer, using up-to-date software for optimal settings, and implementing quality control checks at every step can ensure consistent, professional results with custom DTF transfers. These practices not only enhance the overall aesthetics but also contribute to a smoother production process, satisfying both printers and customers alike.

DTF film sheets are a crucial component in various industries, demanding meticulous quality control to ensure optimal performance. By understanding the materials and their unique properties, implementing a structured quality control process, and proactively addressing common issues, manufacturers can produce superior DTF film sheets. Adhering to these insights not only enhances product consistency but also safeguards against potential drawbacks, ultimately fostering trust among consumers and ensuring a competitive edge in the market.