Understanding modern consumer preferences is crucial for unlocking the full potential of DTF Hot Peel Films in the market. Today's consumers demand high-quality, customized products, driving a shift towards specialized packaging. Manufacturers are leveraging advanced technologies to produce versatile DTF gang sheets suitable for promotional materials, point-of-sale displays, and industrial packaging. The ability to offer on-demand, custom DTF solutions meets consumer expectations, positioning these films as essential tools for efficient and effective packaging strategies. Key trends include enhanced print quality, speed, and durability, along with a focus on accommodating smaller orders and sustainable production methods.

“In today’s competitive market, understanding consumer demand is key to unlocking the full potential of the DTF Hot Peel Film industry. This article delves into the intricate relationship between consumer preferences and the evolution of DTF Hot Peel Films. We explore how market dynamics drive innovation, highlighting key features and trends that shape this sector. Furthermore, we discuss strategic approaches to meet rising expectations for customization, sustainability, and more, ensuring the industry’s continued growth.”

- Understanding Consumer Preferences: Unlocking the Market's Potential for DTF Hot Peel Films

- The Impact of Demand on Innovation: Key Features and Trends Shaping the Industry

- Strategies to Meet Consumer Expectations: Customization, Sustainability, and Beyond

Understanding Consumer Preferences: Unlocking the Market's Potential for DTF Hot Peel Films

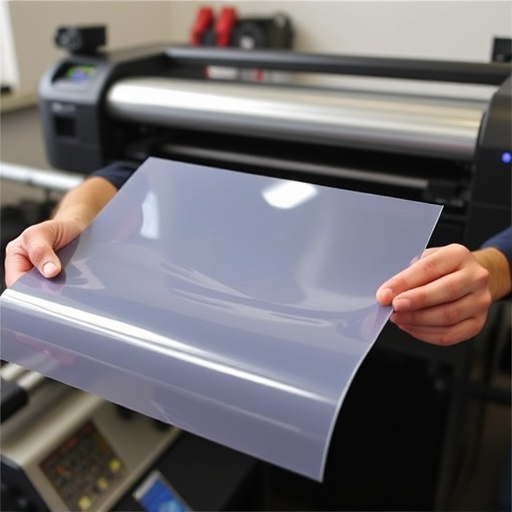

Understanding consumer preferences is key to unlocking the immense potential for DTF Hot Peel Films in the market. Today’s consumers demand products that are not only high-quality but also tailored to their specific needs and preferences. This shift towards customization has significantly impacted various industries, and the world of packaging is no exception. For DTF Hot Peel Films, this means creating solutions that cater to a wide range of applications, from promotional materials and point-of-sale displays to specialized industrial packaging.

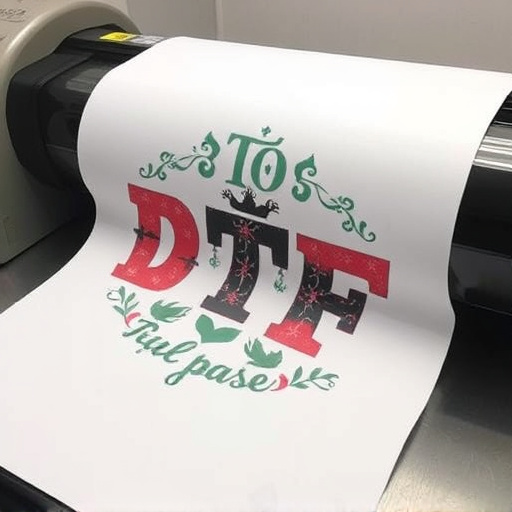

By leveraging advanced technologies and innovative design approaches, manufacturers can develop custom DTF gang sheets that offer unparalleled versatility. These sheets, when utilized in DTF transfer by size, allow for precise application across diverse substrates, further enhancing their market appeal. The ability to create on-demand, customized dtf gang sheet builder solutions not only meets but exceeds consumer expectations, positioning these films as indispensable tools for businesses seeking efficient and effective packaging strategies.

The Impact of Demand on Innovation: Key Features and Trends Shaping the Industry

The demand for DTF Hot Peel Film is a powerful catalyst for innovation within the industry. As consumers increasingly seek unique and personalized products, manufacturers are responding with advanced technologies and features. Key trends in DTF printing services showcase this evolution, with a focus on enhancing print quality, speed, and versatility. One notable trend is the integration of more vibrant and durable inks, enabling intricate designs that captivate end-users.

Additionally, the ability to accommodate smaller orders without compromising efficiency has gained prominence, catering to niche markets and personalized requests. This shift reflects a responsive industry that prioritizes flexibility and accessibility in the DTF printing process. As a result, businesses can offer tailored solutions, ensuring customer satisfaction and staying ahead of the competitive curve.

Strategies to Meet Consumer Expectations: Customization, Sustainability, and Beyond

To meet the evolving demands of consumers, DTF Hot Peel Film manufacturers are adopting innovative strategies that go beyond basic customization. One key trend is the increasing demand for direct to film transfers (DTF) that offer unparalleled levels of detail and accuracy in color reproduction, catering to both professional and hobbyist users. This technology allows for DTF custom orders, enabling clients to personalize their films according to specific needs and preferences.

Sustainability is another critical aspect driving DTF Hot Peel Film innovation. Consumers are increasingly conscious of the environmental impact of their purchases, pushing manufacturers to develop more eco-friendly production processes and materials. By prioritizing sustainability, these companies not only meet consumer expectations but also contribute to a DTF cost-effective solution that balances quality with responsible manufacturing practices.

DTF Hot Peel Films are transforming the packaging industry by meeting evolving consumer demands. As preferences shift towards innovative, convenient, and sustainable solutions, manufacturers are incorporating advanced features into these films. By understanding consumer expectations and embracing customization, sustainability, and emerging trends, the DTF Hot Peel Film market is poised for significant growth. This data-driven approach ensures that products not only meet but exceed consumer needs, solidifying the film’s position as a game-changer in packaging innovation.