Direct-to-Film (DTF) transfers are a cutting-edge print production method for creating high-resolution prints directly on film, ideal for cinema, photography, and graphic design professionals. The process involves specialized equipment transferring ink onto coated film, offering vibrant, detailed prints for various applications. DTF Printing requires advanced scanning, software enhancement, and strict quality control to ensure superior results. Material selection, including durable vinyl for outdoor use and high-quality paper for indoor, is crucial for tailored outcomes. Precision techniques capture intricate details, while multi-stage quality control guarantees exceptional print quality. Professional DTF services provide top-tier prints, suitable for short-run productions, custom designs, and diverse materials, catering to businesses and artists.

“Unleash the power of direct-to-film (DTF) transfers with our comprehensive guide tailored for professionals. This article navigates the intricate world of DTF printing, offering insights into creating high-quality prints that rival cinema standards. From understanding the fundamentals of DTF to selecting top-tier materials and mastering precision techniques, we cover it all. Discover how these professional services enhance various industries, ensuring optimal results with meticulous quality control. Elevate your projects with the art of DTF transfer.”

- Understanding Direct-to-Film (DTF) Transfers: A Professional's Guide

- The Process of Creating High-Quality DTF Prints

- Choosing the Right Materials for Optimal DTF Transfer Results

- Techniques to Ensure Precision and Detail in DTF Printing

- Quality Control and Inspection for DTF Transfers

- Benefits and Applications of Professional DTF Transfer Services

Understanding Direct-to-Film (DTF) Transfers: A Professional's Guide

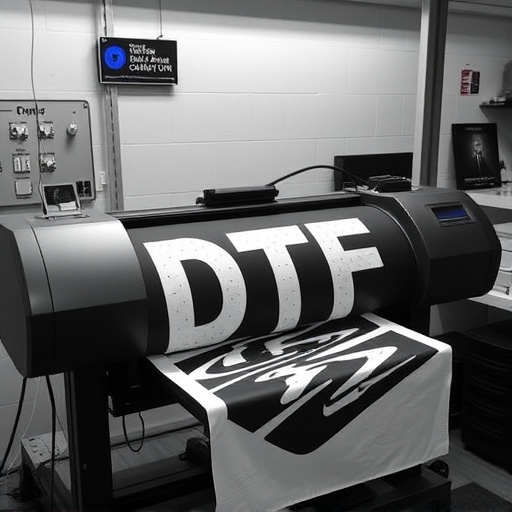

Direct-to-Film (DTF) Transfers are a cutting-edge method in print production that offers unparalleled quality and efficiency for creating high-resolution prints directly on film. This process is particularly valuable for professionals in industries like cinema, photography, and graphic design who require precise, accurate, and fast printing solutions. DTF Printing involves specialized equipment that transfers ink onto a coated film, enabling the creation of detailed, vibrant prints suitable for various applications, from large-format displays to fine art reproduction.

As a professional, mastering DTF Transfers opens up a world of creative possibilities. It allows for on-demand printing, eliminating the need for bulky presses or complex setups. DTF Transfer technology ensures that every detail is captured with exceptional clarity and color accuracy, resulting in prints that rival traditional printing methods. This guide aims to provide an insightful overview for professionals interested in integrating DTF into their workflow, exploring the process, benefits, and best practices for achieving optimal results with this innovative technique.

The Process of Creating High-Quality DTF Prints

The creation of high-quality Direct-to-Film (DTF) transfers involves a meticulous process that demands precision and expertise. It begins with preparing the original film, ensuring it’s clean and free from any damage. This may include digitizing the film frame by frame, using advanced scanning equipment to capture every detail accurately. Once scanned, specialized software is employed to enhance the image quality, adjust colors, and ensure optimal clarity for printing.

The next step is the actual DTF printing process. High-resolution printers are used to transfer the digital image onto a suitable film stock. The printer’s precision and the quality of ink play a significant role in achieving vibrant, accurate colors. After printing, the film is carefully inspected for any defects or inconsistencies. This rigorous quality control ensures that the final DTF prints meet the highest standards, delivering an authentic viewing experience akin to the original film.

Choosing the Right Materials for Optimal DTF Transfer Results

When creating direct-to-film (DTF) transfers for customers, selecting the appropriate materials is key to achieving exceptional results. The first step involves understanding the intended use of the final product. For instance, if the DTF prints will be exposed to outdoor elements or used in high-traffic areas, a durable vinyl with UV protection may be the best choice. On the other hand, for indoor applications like decorations or signage, a higher-quality paper or canvas could offer better detail and visual appeal.

Additionally, the type of ink used plays a significant role. For outdoor durability, solvent-based inks are recommended due to their resistance to fading and weather conditions. For interior use, however, latex or UV-curable inks can produce vibrant colors and crisp details while being suitable for various printing surfaces. By carefully considering these material options, professionals can ensure optimal DTF transfer outcomes tailored to each customer’s unique needs.

Techniques to Ensure Precision and Detail in DTF Printing

In the professional creation of direct-to-film (DTF) transfers for customers, ensuring precision and detail in DTF printing is paramount. High-resolution imaging techniques play a crucial role, capturing intricate details from original art or source materials. Using advanced scanners capable of 4K resolution or higher allows for accurate color representation and fine line reproduction, resulting in precise DTF prints.

Moreover, the use of specialized inks and coatings enhances print quality. High-quality UV curable inks offer vibrant colors and exceptional durability, while anti-glare or protective coatings can add a layer of protection to the final DTF transfer, ensuring its longevity. Precise registration techniques during printing are also essential to maintain the integrity of designs, especially when combining multiple layers or elements in a single DTF print.

Quality Control and Inspection for DTF Transfers

The professional creation of direct-to-film (DTF) transfers demands a meticulous approach to quality control and inspection. Every step of the process, from film selection to print application, must adhere to stringent standards to ensure optimal DTF results. Experts in this field employ advanced techniques to verify the integrity of each transfer, scrutinizing factors like resolution, color accuracy, and edge definition. High-resolution imaging and specialized lighting are often used to detect even the slightest imperfections in the final DTF prints.

Rigorous quality control involves a multi-stage inspection process. This includes visual examinations under controlled lighting conditions to identify any flaws or inconsistencies. Additionally, dynamic testing methods like print contrast analysis and color density checks ensure that every DTF transfer meets the required specifications. By maintaining rigorous quality standards, professionals guarantee that customers receive top-quality DTF prints, preserving the intended artistic vision for film enthusiasts and collectors alike.

Benefits and Applications of Professional DTF Transfer Services

Professional direct-to-film (DTF) transfer services offer a multitude of benefits for customers seeking high-quality prints. By leveraging advanced technologies and expert knowledge, these services ensure precise color reproduction, crisp details, and durable finishes that surpass traditional printing methods. DTF Printing is particularly well-suited for short-run productions, custom designs, and intricate patterns, making it an ideal solution for a diverse range of applications.

From promotional merchandise to custom art pieces, DTF Transfer services cater to various industries. For instance, businesses can create personalized items like phone cases, mugs, or apparel with intricate graphics and photos. Artists, too, find this method invaluable for reproducing fine art prints, ensuring their creations maintain the original artist’s intent. Moreover, DTF prints are versatile enough to be applied to a variety of materials, including fabric, metal, and wood, expanding the creative possibilities for both businesses and individuals alike.