Direct-To-Film (DTF) transfer technology has revolutionized printing by enabling creation of intricate, detailed designs on various surfaces. This process involves transferring digital images to film for etching fine lines onto metal, glass, and other materials with remarkable accuracy, offering superior line resolution, versatility, and production of complex artwork as thin as 0.1 millimeters. DTF Printing is popular among professionals for high-quality prints in custom metal signage, artistic installations, and industrial components. It has transformed sectors like fashion, art, and manufacturing by providing a cost-effective, precise solution for achieving intricate designs with enhanced line clarity and print quality.

In the realm of precision printing, DTF (Direct To Film) transfer technology stands out for its ability to reproduce thin lines and intricate details with remarkable accuracy. This article delves into the intricacies of DTF transfers, highlighting their advantages over traditional methods in achieving detailed prints. We explore key components essential for accurate reproduction, provide a step-by-step guide to the DTF printing process, address common challenges, and showcase diverse real-world applications of DTF prints.

- Understanding DTF Transfer Technology

- Advantages of Using DTF for Thin Line Reproduction

- Key Components in Achieving Accurate Details

- Step-by-Step Guide to DTF Printing Process

- Common Challenges and Their Solutions

- Real-World Applications of DTF Prints

Understanding DTF Transfer Technology

The DTF (Direct-To-Film) transfer technology has revolutionized the printing industry, particularly in creating intricate and detailed designs on various surfaces. This innovative process involves transferring a digital image directly onto a film, which is then used to etch fine lines and delicate patterns onto metal, glass, or other materials. The beauty of DTF lies in its ability to reproduce thin lines with remarkable accuracy, ensuring every detail is crisp and precise. This technology has gained immense popularity among professionals who demand high-quality, detailed prints, such as custom metal signage, decorative accents, and architectural elements.

DTF Printing offers a range of advantages, from superior line resolution to unmatched versatility in materials. The technique allows for the creation of complex artwork with lines as thin as 0.1 millimeters, making it ideal for intricate designs. This level of precision ensures that prints are not just visually stunning but also structurally sound, especially when applied to functional objects. DTF Transfers have become a game-changer, enabling creators and manufacturers to bring their most detailed visions to life across diverse applications, from artistic installations to industrial components.

Advantages of Using DTF for Thin Line Reproduction

Using DTF (Direct to Film) transfer technology offers significant advantages when it comes to reproducing thin lines and intricate details in printing. This innovative process allows for exceptional accuracy, ensuring that even the most delicate linework is precisely replicated on various materials. DTF Printing provides a high level of control over line thickness, enabling printers to achieve precise and consistent results.

With DTF, the potential for fine detail reproduction is unparalleled. The technology’s ability to capture intricate patterns and lines with exceptional clarity makes it ideal for creating detailed designs, technical drawings, and artwork that requires sharp, accurate lines. This advantage is particularly valuable in industries such as engineering, architecture, and graphic design where precise illustrations are essential. DTF Transfers have revolutionized printing by providing a cost-effective solution for producing high-quality, detailed prints while maintaining the original line integrity.

Key Components in Achieving Accurate Details

Achieving accurate detail reproduction in transfers, especially those with thin lines and intricate designs, relies on several key components. Firstly, the DTF (Direct to Film) transfer process plays a pivotal role. This technology allows for precise printing directly onto the transfer material, ensuring every line and curve is captured flawlessly. The quality of the DTF prints is influenced by the resolution and color depth of the digital file, making high-quality source art indispensable.

Additionally, the choice of DTF transfer media significantly impacts outcome. Specialized films designed for detail-rich transfers offer improved clarity and adhesion, enabling crisp reproduction even in the tiniest gaps. Proper pre-press preparation, including cleaning and activating the substrate, is equally crucial to guarantee a secure bond between the transfer and the final material, be it fabric, leather, or wood.

Step-by-Step Guide to DTF Printing Process

The Direct to Form (DTF) printing process offers a precise and efficient method for creating high-quality prints with intricate details. Here’s a step-by-step guide to help you master this technique:

1. Design Preparation: Start by designing or sourcing artwork that features thin lines and delicate details. Ensure your design is optimized for DTF, with line weights suitable for the process. Use vector graphics or high-resolution raster images for best results.

2. Setting Up Your Workspace: Prepare a clean workspace equipped with a DTF printer, a computer running specialized printing software, and necessary materials like DTF transfer sheets and ink. Calibrate your printer according to the manufacturer’s instructions to achieve accurate color reproduction and line accuracy.

3. Loading and Pre-press: Load the DTF transfer sheet into the printer, ensuring proper alignment. The software will guide you through the pre-press stage, allowing you to adjust settings like print resolution, ink type, and printing mode to match your design’s requirements.

4. Printing Process: Initiate the print job. The DTF printer will precisely deposit ink onto the transfer sheet, accurately reproducing your design’s thin lines and details. Monitor the process for any errors or misalignments.

5. Curing and Application: After printing, cure the ink according to the recommended settings for your specific DTF system. Once cured, carefully apply the transfer sheet to your desired substrate, such as fabric, wood, or metal, using a hot press or iron. Ensure even pressure for a crisp, detailed finish.

6. Post-Processing: Remove any excess transfer material and inspect your print. Touch up any imperfections if needed. DTF prints deliver exceptional line accuracy and detail reproduction, making them ideal for applications requiring intricate designs.

Common Challenges and Their Solutions

In the pursuit of creating precise and detailed designs, especially in fields like graphic arts, manufacturing, and fashion, one often encounters challenges when attempting to transfer intricate patterns and thin lines. This is where DTF (Direct to Forme) transfers prove invaluable. Common hurdles include ensuring line clarity, preventing smudging or misalignment during the transfer process, and achieving consistent print quality across various materials.

However, DTF Printing offers robust solutions to these issues. The technique utilizes advanced technology to produce high-resolution DTF prints, making it ideal for intricate designs. Specialized inks and precise printing mechanisms ensure that thin lines remain crisp and accurate. Furthermore, the direct application method minimizes the risk of smudging, allowing for detailed transfers onto various surfaces. This makes DTF Printing a go-to method for achieving flawless, detailed reproductions in numerous applications, including fashion design, custom art pieces, and manufacturing prototypes.

Real-World Applications of DTF Prints

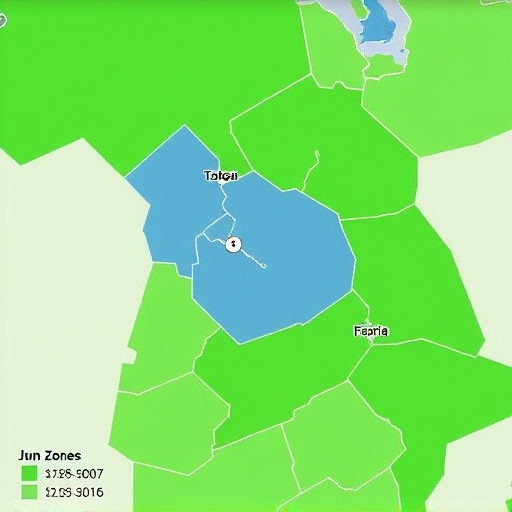

In various industries, DTF (Direct to Fabric) Transfers have become a game-changer for achieving precise and intricate designs. From fashion and apparel to decorative arts, DTF Prints offer an efficient method for reproducing complex patterns and details directly onto fabric. This technology enables artisans and designers to create vibrant, detailed artworks that were once laborious to achieve.

Real-world applications of DTF Transfers span diverse fields. In the fashion industry, clothing brands utilize DTF Printing to incorporate unique, personalized designs onto garments, allowing for limited-edition pieces and custom orders. For interior decorators, creating custom fabric patterns for curtains, throw pillows, or upholstery has become streamlined, offering clients a vast array of customizable options. Additionally, DTF Transfers find use in signmaking, enabling the production of high-quality, long-lasting graphics for outdoor signage, banners, and promotional materials.