Direct-to-film (DTF) printing is a cutting-edge technology in commercial printing, delivering high-quality, vibrant images for outdoor displays and packaging. It offers versatile media support, fast turnaround times, and customizable sizes, making it an efficient solution for marketing materials. The process involves a collaborative creative journey, rigorous quality assurance, and precise control to maintain superior print quality. DTF has successfully enhanced brand visibility and customer engagement in various sectors through case studies, demonstrating its revolutionary impact on visual communication. To achieve optimal results, focus on high-quality film stock preparation, equipment calibration, and meticulous attention to detail throughout the printing process.

“Direct-to-film (DTF) printing is a game-changer for commercial clients seeking high-quality, visually stunning outputs. This production method offers precise color reproduction and crisp details, making it ideal for various applications from branding to pop culture merchandise. In this article, we’ll guide you through the world of DTF prints, exploring its benefits, in-depth production process, quality control measures, and real-world case studies. Learn how DTF can elevate your projects, and discover best practices for exceptional results.”

- Understanding Direct-to-Film (DTF) Printing: An Overview for Commercial Clients

- Benefits of Choosing DTF Prints for Your Project

- The Process: From Concept to Final Product

- Quality Assurance and Control in DTF Production

- Case Studies: Successful DTF Projects in the Commercial Sector

- Best Practices and Tips for Optimal DTF Results

Understanding Direct-to-Film (DTF) Printing: An Overview for Commercial Clients

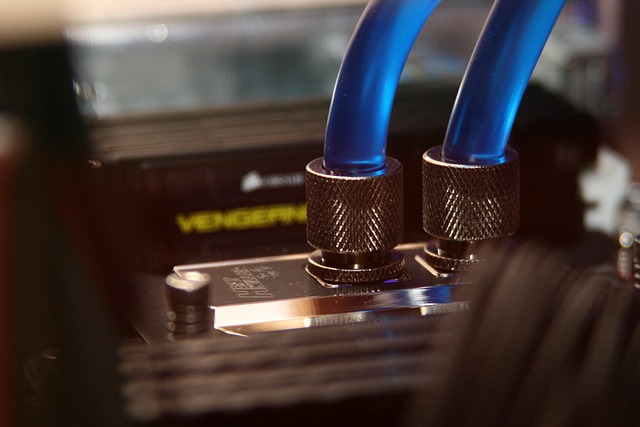

Direct-to-film (DTF) printing is a cutting-edge technique revolutionizing commercial printing, offering exceptional quality and versatility for various applications. This innovative process involves transferring ink directly onto film, bypassing traditional intermediate steps, resulting in crisp, vibrant DTF prints. The method is particularly advantageous for clients seeking high-resolution, durable images suitable for outdoor displays, packaging, or promotional materials.

DTF technology allows for a wide range of media types and sizes, catering to diverse commercial needs. From large-format billboards to intricate packaging designs, the versatility of DTF printing ensures that businesses can achieve exceptional visual impacts without compromising quality or durability. This efficient process reduces production time and waste, making it an attractive solution for companies looking to enhance their marketing campaigns with impactful visuals.

Benefits of Choosing DTF Prints for Your Project

Choosing Direct-to-Film (DTF) prints for your project offers numerous advantages that can significantly enhance its impact and effectiveness. Firstly, DTF technology allows for incredibly high-resolution outputs, ensuring your visuals are crisp and detailed, perfect for catching the attention of commercial audiences. This method directly prints onto various media, eliminating the need for intermediate steps, which reduces potential issues like misalignment or degradation in quality.

Moreover, DTF Prints provide exceptional color accuracy and vibrant hues, making them ideal for branding and marketing materials where maintaining brand identity is crucial. The direct application to glass, acrylic, or other transparent media enables unique display options, creating engaging, immersive experiences for your clients’ products. With fast turnaround times and the ability to customize sizes, DTF production is a versatile, efficient solution for commercial projects seeking high-quality, visually striking results.

The Process: From Concept to Final Product

The direct-to-film (DTF) transfer production process for commercial clients is an artful journey, meticulously crafted to bring creative visions to life on screen. It all begins with a concept—a client’s idea or a director’s vision. This initial phase involves extensive communication and collaboration between the production team and the client to ensure a clear understanding of the desired outcome. Storyboards and pre-production planning are essential tools to visualize and map out the final product.

As the process unfolds, high-quality source materials, such as prints or digital files, are prepared for transfer. The experts carefully select the appropriate film stock, considering factors like resolution, color accuracy, and grain structure to match the original intent. Each frame is then precisely transferred onto film, layer by layer, creating a negative that will serve as the master copy. This meticulous step ensures optimal image quality and allows for any necessary adjustments before the final print is made. Once approved, the negative undergoes a carefully controlled printing process, producing vibrant DTF prints ready to captivate audiences.

Quality Assurance and Control in DTF Production

In direct-to-film (DTF) production for commercial clients, Quality Assurance (QA) and Control are paramount to ensure the superior quality of final DTF prints. Rigorous QA processes involve meticulous monitoring at every stage, from raw material inspection to print evaluation. This includes checking for color accuracy, resolution, and consistency across the entire run, ensuring that each print meets or exceeds client expectations.

Control mechanisms in DTF production leverage advanced technologies like calibrated measurement tools and high-resolution scanners to catch even subtle deviations. Regular calibration of equipment and ongoing training for staff ensure a consistent standard of excellence. By implementing these QA and control measures, DTF production facilities can guarantee the aesthetic integrity and precision of their commercial prints, solidifying their reputation in a competitive market.

Case Studies: Successful DTF Projects in the Commercial Sector

In the commercial sector, direct-to-film (DTF) printing has emerged as a game-changer for marketing and advertising campaigns. Case studies highlight its success in various projects, showcasing the versatility and quality of DTF prints. For instance, a leading fast-food chain utilized DTF technology to create vibrant, large-scale outdoor billboards, significantly enhancing their brand visibility during peak hours in bustling metropolitan areas.

Another notable example involves a retail giant that implemented DTF-printed displays for its seasonal promotions. The ability to produce high-resolution, color-accurate prints on demand allowed them to swiftly adapt to market trends, resulting in increased customer engagement and improved sales. These real-world applications underscore the efficiency and effectiveness of DTF production methods in meeting commercial clients’ diverse visual communication needs.

Best Practices and Tips for Optimal DTF Results

When aiming for optimal Direct-to-Film (DTF) print results, a few best practices stand out. First, ensuring your film stock is of high quality and suitable for DTF printing is paramount. Choose films designed specifically for this process to achieve the best color accuracy and sharpness in the final prints. Additionally, proper preparation of the film is crucial; clean it thoroughly to remove any contaminants that could affect the print quality.

Another key tip is to calibrate your equipment regularly. Precise exposure settings and consistent press operation are essential for DTF success. Use test prints to fine-tune your process and maintain a consistent pressure and ink application during production runs. Remember, attention to detail at every step—from film selection to printing techniques—will result in exceptional DTF Prints that meet commercial client expectations.