Real-world performance verification is crucial for Cold Air Intake (CAI) systems, ensuring their design optimizes engine power and fuel efficiency. The method includes dynamic testing with sensors measuring temperature, pressure, and flow rates before and after CAI installation under diverse driving conditions. By comparing real data with theoretical predictions, engineers validate or optimize the CAI's performance, enhancing vehicle dynamics, fuel economy, and emissions reduction. This systematic approach blends theory and practice to accurately assess the CAI's impact on engine performance.

Real-world performance verification is a critical process ensuring vehicles meet expected standards in everyday conditions. This article delves into three key aspects: understanding real-world performance, exploring the significance of cold air intake performance testing, and examining effective evaluation methodologies. By implementing these strategies, we can ensure optimal engine performance, efficiency, and reliability. Specifically, the focus on cold air intake performance testing methodology highlights a vital step in achieving accurate real-world results.

- Understanding Real-World Performance Verification

- The Role of Cold Air Intake Performance Testing

- Methodology for Effective Real-World Performance Evaluation

Understanding Real-World Performance Verification

Real-world performance verification is a critical process that goes beyond bench testing, aiming to assess how a vehicle or engine performs in actual driving conditions. It involves using specialized techniques and tools to measure and analyze key metrics during normal operation. In the context of cold air intake (CAI) systems, this verification is essential as it can significantly impact engine power and efficiency.

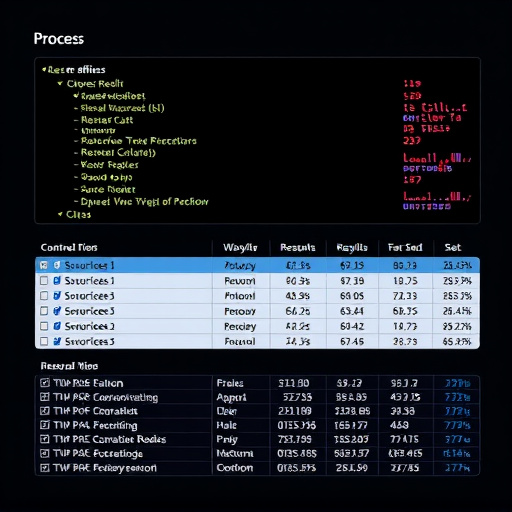

The methodology typically includes dynamic testing where sensors are employed to monitor changes in engine parameters like temperature, pressure, and flow rates both before and after the CAI installation. These tests are conducted under various driving scenarios, ensuring a comprehensive evaluation of the intake’s performance gains. By comparing the real-world results with theoretical predictions, engineers can validate or fine-tune the CAI’s design, ultimately delivering improved vehicle performance and fuel economy.

The Role of Cold Air Intake Performance Testing

In real-world performance verification, Cold Air Intake (CAI) plays a pivotal role in optimizing engine efficiency and power output. The cold air intake performance testing methodology involves evaluating how effectively a CAI system delivers cool, dense air to the engine, enhancing its ability to burn fuel efficiently. This process is crucial as it can significantly impact vehicle dynamics, especially in high-performance cars and race vehicles.

The testing methodology includes measuring flow rates, air temperature, and pressure differentials at various speeds and load conditions. By comparing these metrics against theoretical models and manufacturer specifications, engineers can identify performance gaps and fine-tune the CAI design for optimal efficiency. This data-driven approach ensures that the cold air intake not only enhances performance but also contributes to improved fuel economy and reduced emissions, making it a critical component in modern automotive engineering.

Methodology for Effective Real-World Performance Evaluation

When conducting real-world performance verification for cold air intake (CAI) systems, a systematic approach is crucial to ensure accurate and reliable results. The methodology should involve a combination of theoretical analysis and practical testing. Start by thoroughly studying the CAI’s design and specifications, understanding its claimed benefits and potential impacts on engine performance. This initial step provides a baseline for comparison during testing.

Next, select appropriate test scenarios that mimic real-world driving conditions. This includes varying speeds, altitudes, and engine loads. Utilise advanced instrumentation to measure key parameters such as air flow rates, pressure differentials, and temperature changes before and after the CAI. By analyzing these data points, you can quantify the CAI’s performance gains or any potential issues that might affect overall engine efficiency and power output.

Real-world performance verification is an indispensable process in automotive tuning, ensuring modifications enhance vehicle dynamics rather than hinder them. By combining scientific methodologies with practical testing, such as cold air intake performance testing, we gain a deeper understanding of how components interact in real-world scenarios. This approach allows for informed decisions, leading to optimized engine performances without compromising reliability. Adopting effective evaluation methods, including systematic data collection and analysis, is crucial for achieving accurate results, ultimately benefitting both enthusiasts and professionals in the automotive industry.