DTF (Direct-to-Fabric) Prints revolutionize textile design by enabling intricate patterns and vibrant colors to be permanently bonded to polyester fabrics with unparalleled precision. This modern method eliminates traditional steps, offering a versatile solution for fashion, home decor, and promotional items. Polyester's superior strength and smooth surface make it ideal for DTF prints, ensuring long-lasting, detailed artwork resistant to fading. The process involves carefully balancing ink viscosity, printing temperature, and curing methods to achieve optimal adhesion. Direct to fabric (DTF) printing produces professional results suitable for various applications, with future trends suggesting deeper integration of smart fabrics and interactive technologies.

“Discover the revolutionary world of DTF (Direct to Fabric) prints, a game-changing technique transforming the textile industry. This article explores the art of transferring films onto polyester fabrics, offering an innovative and efficient solution for diverse applications. From understanding the fundamentals of DTF prints to delving into the evolution, material choices, formulation science, and application methods, we unravel the secrets behind this technology’s rising popularity. Uncover its advantages, explore real-world uses, and gaze into future trends shaping the fabric printing landscape.”

- Understanding DTF Prints: A Brief Overview

- The Evolution of Film Transfers for Fabrics

- Polyester as a Base Material: Properties and Advantages

- Formulating Adhesion: Key Considerations

- Application Techniques for Optimal Results

- End-Use Applications and Future Trends

Understanding DTF Prints: A Brief Overview

DTF (Direct-to-Fabric) Prints, also known as DTP (Direct-to-Polyester), offer a cutting-edge method for applying intricate designs and images directly onto polyester fabrics. This innovative technique revolutionizes traditional printing methods by eliminating the need for intermediate steps like film transfers or screen printing. With DTF, designers can achieve vibrant, long-lasting results with exceptional detail and color accuracy.

The process involves using specialized printers that deposit pigment inks directly onto the fabric’s surface, creating a permanent bond. This direct adhesion ensures that the print remains durable even after repeated washings, making it an ideal choice for various applications, from fashion and home decor to promotional merchandise. DTF Prints deliver a unique blend of aesthetics and functionality, captivating audiences with their crisp visuals and touch-sensitive textures.

The Evolution of Film Transfers for Fabrics

The evolution of film transfers for fabrics, particularly Digital Thermal Transfer (DTF) prints, marks a significant shift in the way we reproduce and integrate visual art with textile design. Traditional methods relied heavily on hand painting or intricate embroidery, limiting both the time invested and the level of detail achievable. With DTF Prints, this landscape has drastically changed. This modern technique allows for high-resolution, full-color imaging directly onto a variety of fabrics, including polyester. The process involves transferring heat-sensitive ink from a film to the fabric, resulting in vibrant, long-lasting prints that rival traditional painting techniques.

This innovation has democratized access to textile design, empowering artists and designers alike. From fashion designers seeking unique material expressions to small businesses looking to create personalized textiles, DTF Prints offer a versatile and efficient solution. Moreover, its compatibility with polyester fabrics, known for their durability and versatility, expands the creative possibilities across numerous industries, from apparel to home decor, revolutionizing how we think about bringing art to life in a tangible form.

Polyester as a Base Material: Properties and Advantages

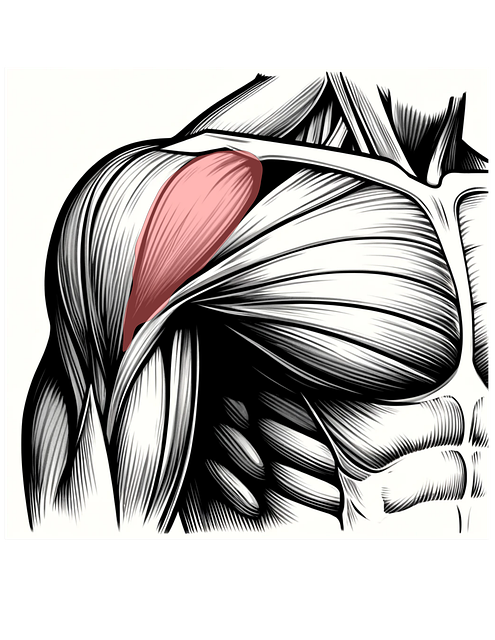

Polyester serves as an ideal base material for film transfers, boasting exceptional strengths that lend itself perfectly to creating durable DTF prints. Its inherent resistance to shrinking and stretching ensures the crispness and longevity of images transferred onto fabric. Furthermore, polyester’s smooth surface facilitates easy application of films, minimizing bubble formation and other transfer defects.

The material’s rigid structure provides a solid foundation for intricate designs, enabling sharp detail retention. Polyester’s affinity for adhering to various coatings enhances the overall durability of DTF prints, making them resistant to fading and cracking over time. This makes polyester-based film transfers a popular choice among artists and designers looking to create vibrant, long-lasting artwork on fabric media.

Formulating Adhesion: Key Considerations

When formulating adhesion for DTF (Direct-To-Fabric) prints involving polyester fabrics, several critical factors come into play. The key consideration is understanding the chemistry behind the inks and the fabric’s surface properties. Polyester, known for its smoothness and durability, requires specific adhesives to ensure proper bonding with ink layers.

The process involves selecting appropriate polymers that can interact effectively with both the fabric and ink. Adhesion promoters or primers might be necessary to enhance the compatibility between these materials. Additionally, factors such as ink viscosity, temperature settings during printing, and curing methods all influence the final adhesion strength. Balancing these variables is essential to achieve long-lasting, vibrant DTF prints on polyester fabrics.

Application Techniques for Optimal Results

To achieve optimal results with film transfers on polyester fabrics, several application techniques can be employed. One effective method is direct to fabric (DTF) printing, which involves transferring the desired image directly onto the polyester surface using heat and pressure. This process ensures a crisp, long-lasting print that becomes an integral part of the fabric itself. DTF Prints offer a vibrant color range and sharp detail, making them ideal for various applications, from fashion to home decor.

Proper preparation of both the fabric and the design is key. Pre-treating the polyester with appropriate primers can enhance adhesion, while using high-quality transfer papers guarantees a precise transfer during the heating process. By controlling temperature and pressure settings, you can prevent smudging or excessive melting of the polyester, resulting in a professional finish that resists fading and maintains its integrity even after multiple washes.

End-Use Applications and Future Trends

The versatility of film transfers formulated for polyester fabrics has opened up a myriad of end-use applications, from fashion and textiles to home décor and even automotive interiors. DTF Prints, or Direct to Fabric Printing, is revolutionizing the way we think about wearable art and custom designs. This technology allows for high-quality, durable prints on a variety of polyester materials, enabling creative professionals to bring their vision to life in ways never before possible.

Looking ahead, the future trends in film transfers and DTF Prints suggest an even greater integration with smart fabrics and interactive technologies. As the demand for unique, personalized, and technologically advanced textiles grows, expect to see innovations that combine aesthetic appeal with functional benefits. This could include responsive fabrics that change color or pattern based on environmental factors or user interaction, paving the way for a new era of dynamic and adaptable DTF Prints.