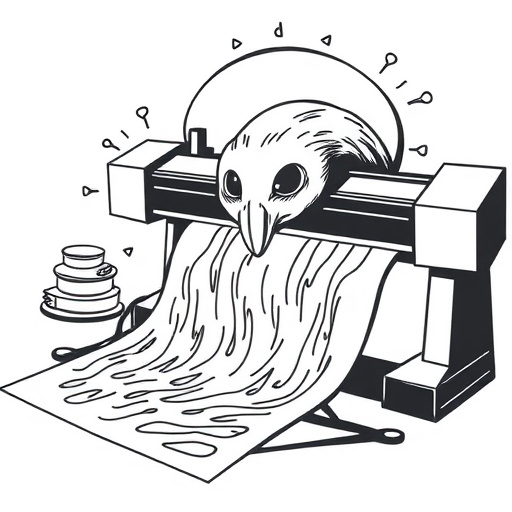

DTF (Direct-to-Film) printing is a cutting-edge technology revolutionizing visual content creation with unparalleled detail and color accuracy. It involves preparing film surfaces, applying specialized inks and coatings, and offers diverse applications from art to 3D printing. Top-tier DTF results heavily depend on high-quality inks and coatings from reputable suppliers. Substrates, ranging from papers to synthetic films, significantly impact print quality and durability, requiring careful selection based on project needs. Advanced techniques like UV curable inks and high-resolution printing enhance detail and color accuracy. The industry boom is driven by demand for customizable, high-quality packaging, with DTF's ability to align with sustainability goals making it a dynamic modern solution. Case studies highlight its versatility across e-commerce, advertising, and fashion industries.

“Unleash the potential of direct-to-film (DTF) printing with our comprehensive guide. This article explores the world of premium DTF transfer products, offering an in-depth look at the process and its advantages. From understanding the fundamentals to uncovering top ink and coating sources, we demystify this cutting-edge technology. Discover how the right substrates and advanced techniques enhance results, while exploring industry trends and inspiring case studies. Dive into the future of DTF printing with these essential insights.”

- Understanding Direct-to-Film (DTF) Printing: An Overview of the Process and Benefits

- Top Sources for High-Quality DTF Ink and Coatings

- The Role of Substrates in DTF Printing: Choosing the Right Material

- Advanced Techniques for Optimal DTF Transfer Results

- Industry Trends and Innovations in DTF Printing Technology

- Case Studies: Successful DTF Printing Projects and Their Secrets

Understanding Direct-to-Film (DTF) Printing: An Overview of the Process and Benefits

Direct-to-Film (DTF) printing is a cutting-edge technology that has revolutionized the way we reproduce and enhance visual content, especially for films and photography enthusiasts. This innovative process allows for high-quality printing directly onto various film types, offering an unparalleled level of detail and color accuracy. The beauty of DTF lies in its ability to capture intricate patterns, textures, and colors from the original film, ensuring a faithful reproduction that brings the visual experience to life.

The DTF printing process involves several steps, starting with the preparation of the film surface, followed by the application of specialized inks and a protective coating. This meticulous approach guarantees not only exceptional print quality but also longevity, as the coated films are resistant to fading and degradation over time. Moreover, DTF printing offers versatility in terms of media types, accommodating different film formats and structures, catering to a wide array of creative applications, from fine art prints to architectural visualizations and even 3D printing materials.

Top Sources for High-Quality DTF Ink and Coatings

When it comes to top-tier DTF Printing, the quality of your ink and coatings plays a pivotal role in achieving exceptional results. To ensure the best output, consider sources renowned for their commitment to excellence and innovation in DTF ink formulation. These suppliers often employ advanced technologies and strict quality control measures to deliver products that meet the highest industry standards.

Among the leading options, you’ll find specialty chemical manufacturers specializing in custom-tailored DTF inks and coatings. They offer a wide range of options catering to specific application needs, from flexible packaging to rigid substrates. Additionally, established printing equipment manufacturers often have their own lines of high-performance DTF inks, providing both the hardware and consumables for seamless integration and optimal results.

The Role of Substrates in DTF Printing: Choosing the Right Material

The choice of substrate is a critical aspect of Direct-to-Film (DTF) printing, as it directly impacts print quality and durability. When selecting materials for DTF applications, consider factors like compatibility with your printing process, desired final product, and environmental considerations. Substrates can range from traditional papers to specialized films, each offering unique properties. For instance, high-quality photo papers provide exceptional image clarity and texture, making them ideal for fine art prints or photography. On the other hand, synthetic materials like polypropylene offer superior durability and water resistance, suitable for outdoor signage or products exposed to harsh conditions.

Understanding the specific requirements of your DTF project is key to making the right substrate choice. Factors such as print resolution, color accuracy, and adhesive properties should be considered in tandem with the end-use case. For instance, if creating labels or packaging, a flexible yet robust substrate may be needed to withstand bending or physical stress. Conversely, for fine art or archival printing, a neutral pH paper might preserve colors and prevent yellowing over time. With so many options available, exploring various substrates allows you to optimize your DTF Printing process and deliver exceptional results tailored to your specific needs.

Advanced Techniques for Optimal DTF Transfer Results

In the realm of DTF Printing, advanced techniques play a pivotal role in achieving optimal transfer results. These methods go beyond the conventional, employing sophisticated strategies to enhance image quality and ensure long-lasting durability. One such technique involves the use of specialized inks designed for direct-to-film applications. These inks are meticulously formulated to offer vibrant colors, exceptional opacity, and resistance to fading, ensuring that the final product retains its visual allure over time.

Additionally, precise printing techniques such as high-resolution digital printing and advanced screen printing methods contribute significantly. High-resolution printers capture intricate details with remarkable accuracy, while screen printing allows for precise control over ink deposition, resulting in crisp lines and sharp edges. Combining these advanced techniques creates a seamless fusion of technology and artistry, transforming direct-to-film transfers into a true masterpiece on various media surfaces.

Industry Trends and Innovations in DTF Printing Technology

The Direct-to-Film (DTF) printing industry is witnessing a surge in innovation, driven by the growing demand for high-quality, on-demand packaging solutions. This technology has evolved significantly over the years, transitioning from traditional screen printing methods to advanced digital printing techniques. Today, DTF Printing offers unparalleled precision and flexibility, enabling manufacturers to produce intricate designs with vibrant colors and exceptional detail. The industry’s trend towards customization and sustainability is also a significant factor, as businesses seek unique, personalized packaging that aligns with eco-conscious consumer preferences.

Innovations such as UV curable inks and advanced printing presses have revolutionized DTF Printing, ensuring faster production times, improved efficiency, and reduced waste. These advancements cater to the rising demand for premium, high-end products across various sectors, including electronics, beauty, and food & beverage. With the ongoing digital transformation, DTF Printing technology continues to adapt, offering businesses an efficient and cost-effective way to meet the dynamic packaging needs of modern markets.

Case Studies: Successful DTF Printing Projects and Their Secrets

Direct-to-film (DTF) printing has transformed various industries, delivering exceptional results in packaging, signage, and even fashion. Examining case studies of successful DTF projects provides valuable insights into its secrets. One standout example is a leading e-commerce retailer who utilized DTF for personalized product packaging. By integrating variable data printing, they achieved unique designs for each customer, enhancing brand engagement and customer satisfaction. The project’s success relied on high-resolution imaging, precise color matching, and a robust DTF printer capable of handling diverse material types.

Another inspiring case involves an outdoor advertising company that adopted DTF for large-scale, high-quality billboards. This approach allowed them to create vibrant, detailed visuals with intricate textures, captivating passersby. The key factors contributing to their success included advanced ink formulations optimized for exterior conditions and a printing process ensuring consistent color accuracy across extensive formats. These case studies highlight the versatility and potential of DTF Printing, setting benchmarks for innovation and quality in modern production processes.